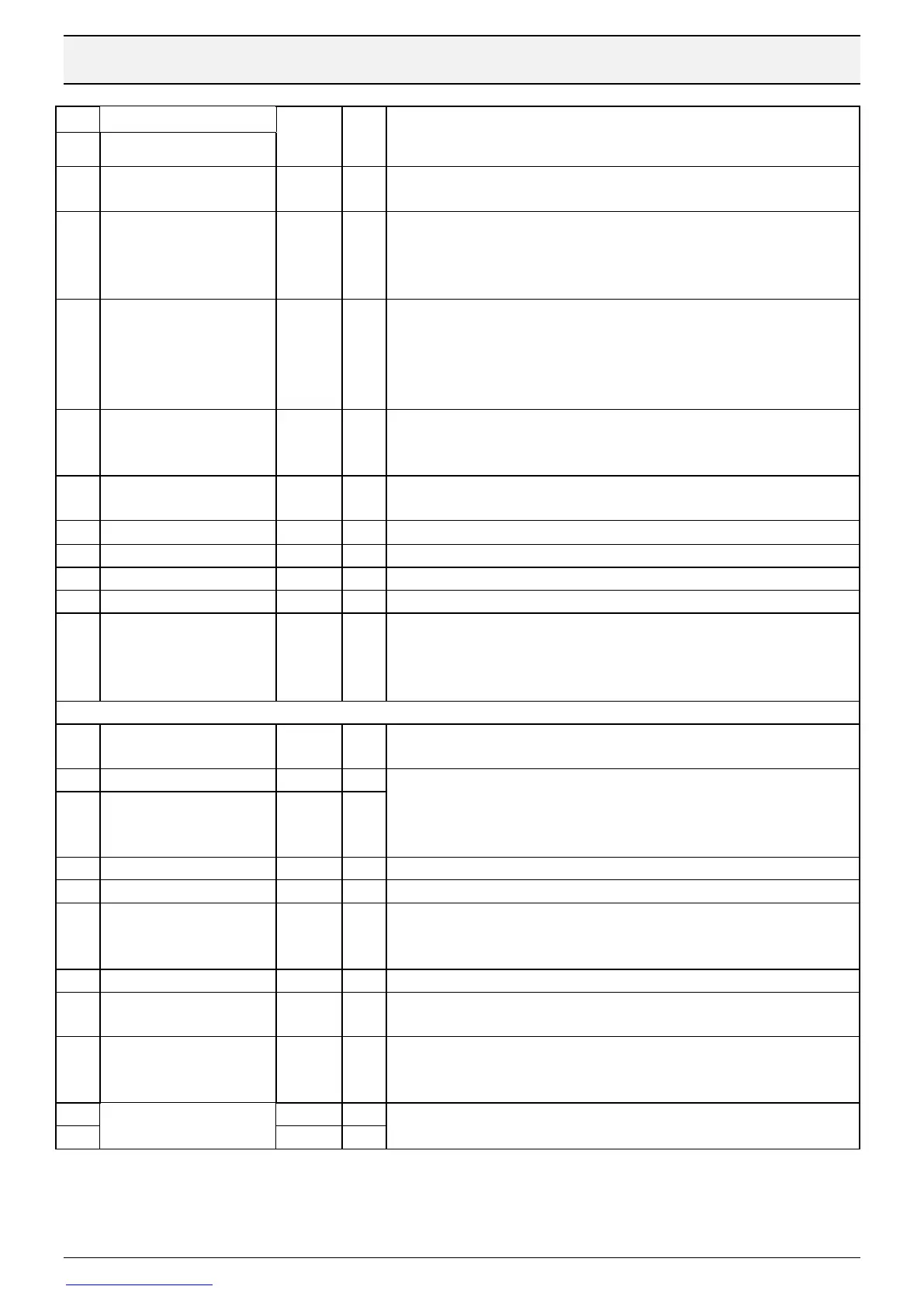

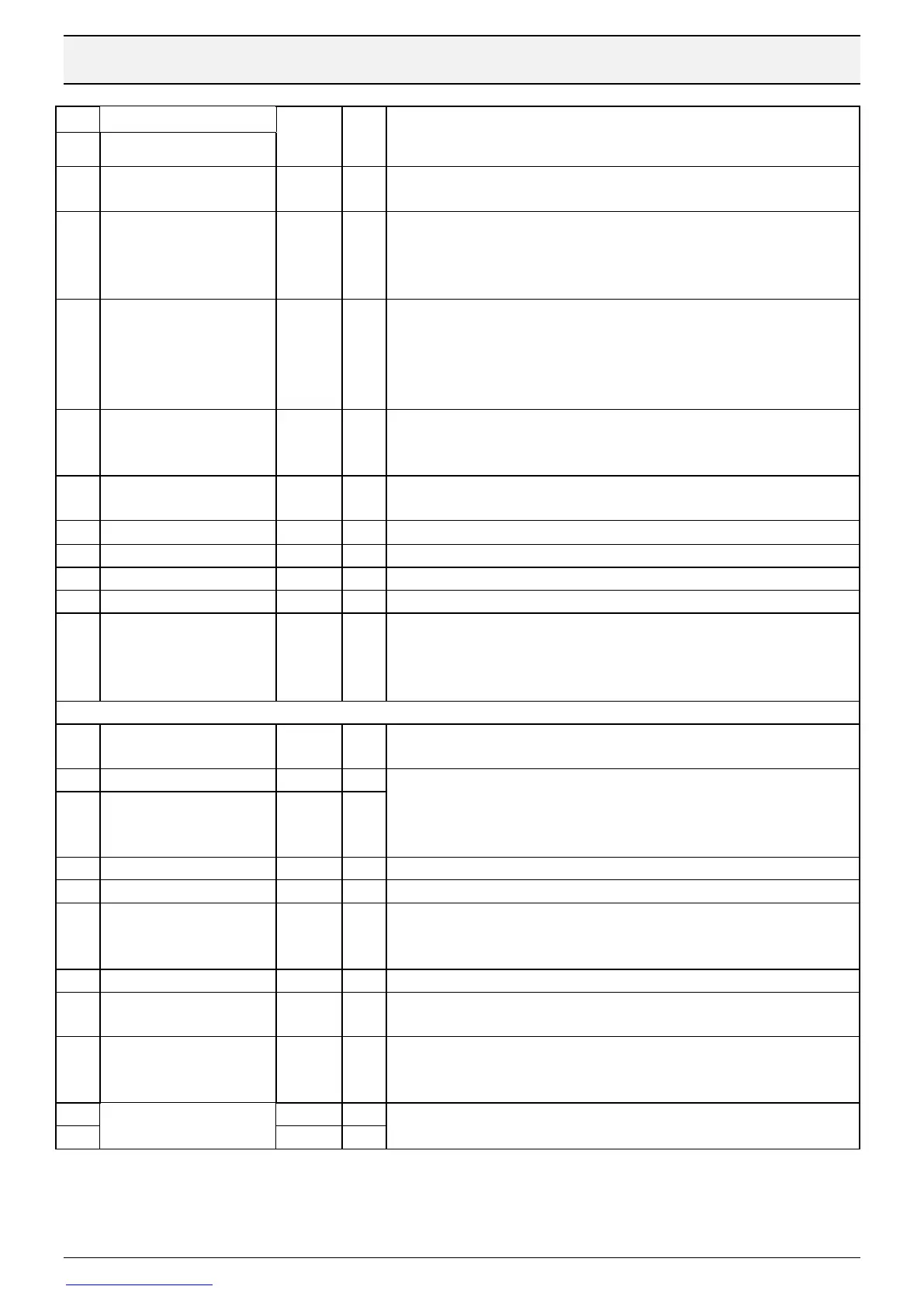

Beijer Electronics Frequency Inverter BFI-H3 KI00363D 2021-07

www.beijerelectronics.com 21 (32)

0: 0-10 V 3: 0-20 mA 4: t 4-20 mA, trip if signal is below 3 mA

5: r 4-20 mA, ramp to Preset Speed4, P2-04, if signal is below 3 mA.

(Setpoint value–Feedback value) of PID controller multiplied by P3-01 to

produce output from PID controller.High value cause instability.

Accumulated error in the PID control between (Setpoint value–Feedback

value) to influence the output from PID controller. P3-02 is time constant.

Larger values provide damped response. Lower values result in a faster

system response but may result in instability. 0= Turned off

The Differential time constant references the rate of change of the

feedback signal over time and works to slow the rate of change of the PID

controller, particularly as it approached the set-point. Shorter time will

decrease overshoot but slow down response and may lead to instability.

0= Turned off.

0: Direct Operation. Increase of motor speed increase feedback signal

1: Inverse Operation. Increase in motor speed should decrease feedback

signal

PID Digital Reference

source

0: PID-reference in P3-06

1: Analog reference on terminal 6

PID–reference: 0-100 % of PID-feedback signal if P3-06=0

Maximum output frequency in % of P1-01

Minimum output frequency in % of P1-01

0 : Analog Input 2 (Terminal 10)

0: Internal ramps are always used.

0,1-100: When PID-error is less than setting internal ramps are not used

and PID–controller ramps output frequency. Drive can react quickly to

small errors.

Extra special PID functions

Scaling factor of displayed PID feedback. If analog input is 0–10 V(=0-

100%) and is equal to 0-10 bar pressure setting is 0,1.

PID Sleep mode parameters. P3-14 defines output frequency at which the

drive will enter standby mode (stop). Drive enters standby mode if motor

speed remains below level in P3-14 for time period in P2-27. Display will

show Standby. Function disabled if P2-27=0.

PID Wake up level. When PID error > P3-13 drive will restart motor.

2nd PID Digital Reference

Second PID reference activated by a digital signal.

≠ 0: Burst pipe protection function enabled.

If PID feedback, when starting motor, is not > P3-17 within time P3-16 the

drive will trip with "Pr-Lo" (pressure low trip).

% of PID feedback signal. See P3-16.

Burst Pipe Detection Trip

Delay

Delay/filtering false trip due to overshoot or undershoot of sensor signal.

For instance pressure shocks due to valves going on and off.

0: PID loop will continue running as long as P gain (P3-01) ≠ 0.

1: PID loop will only run when drive is enabled. If drive is not running, PID

output will reset to 0 (Including integral result).

Drive can be started with speed in P2-07 without PID active. When time

from start in P6-11 has elapsed the drive enters automaticall PID-control.

If PID-control is to be performed by serial, Fieldbus or Ethernet, contact Beijer Electronics.

Loading...

Loading...