Beijer Electronics Frequency Inverter BFI-H3 KI00363D 2021-07

www.beijerelectronics.com 28 (32)

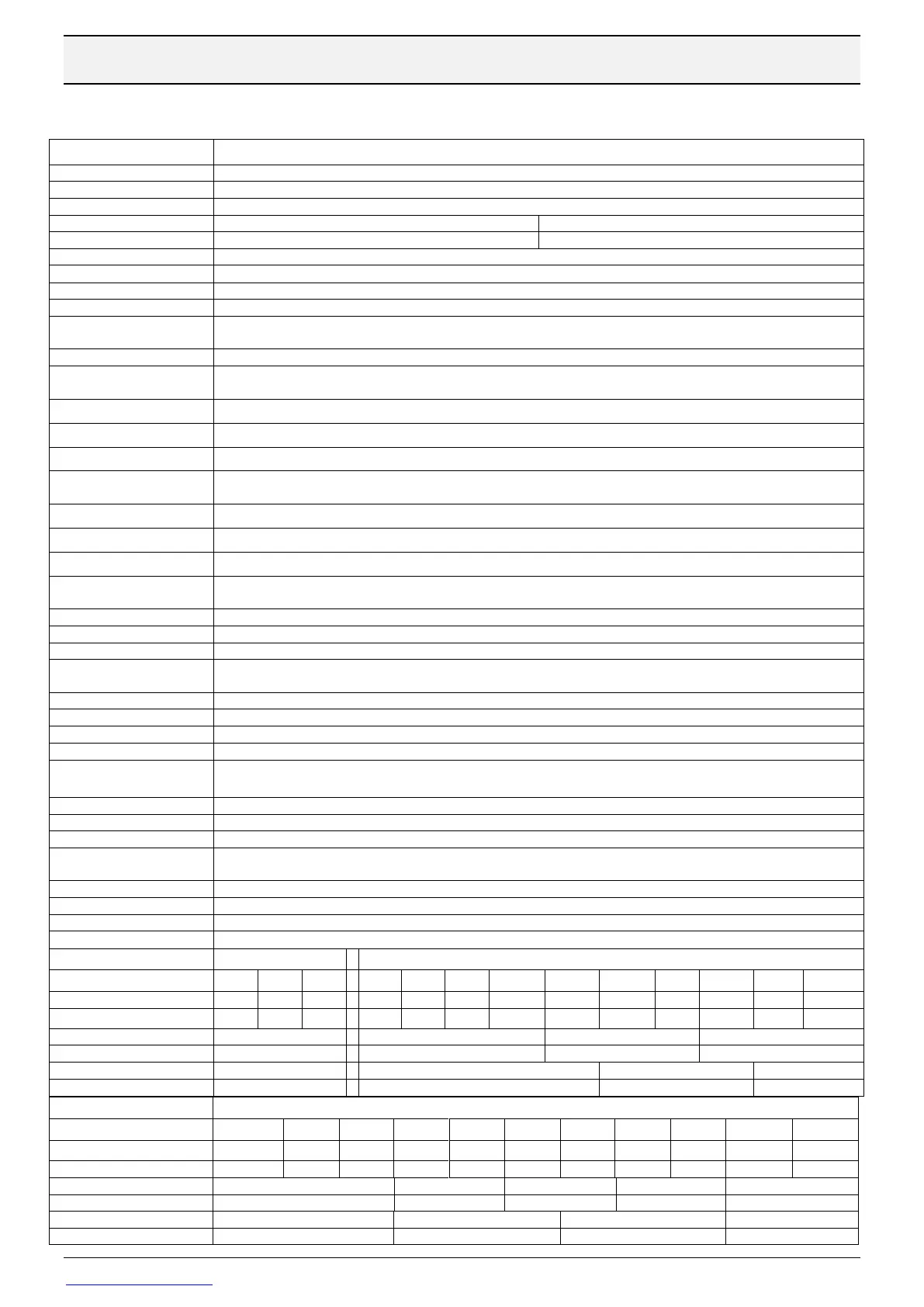

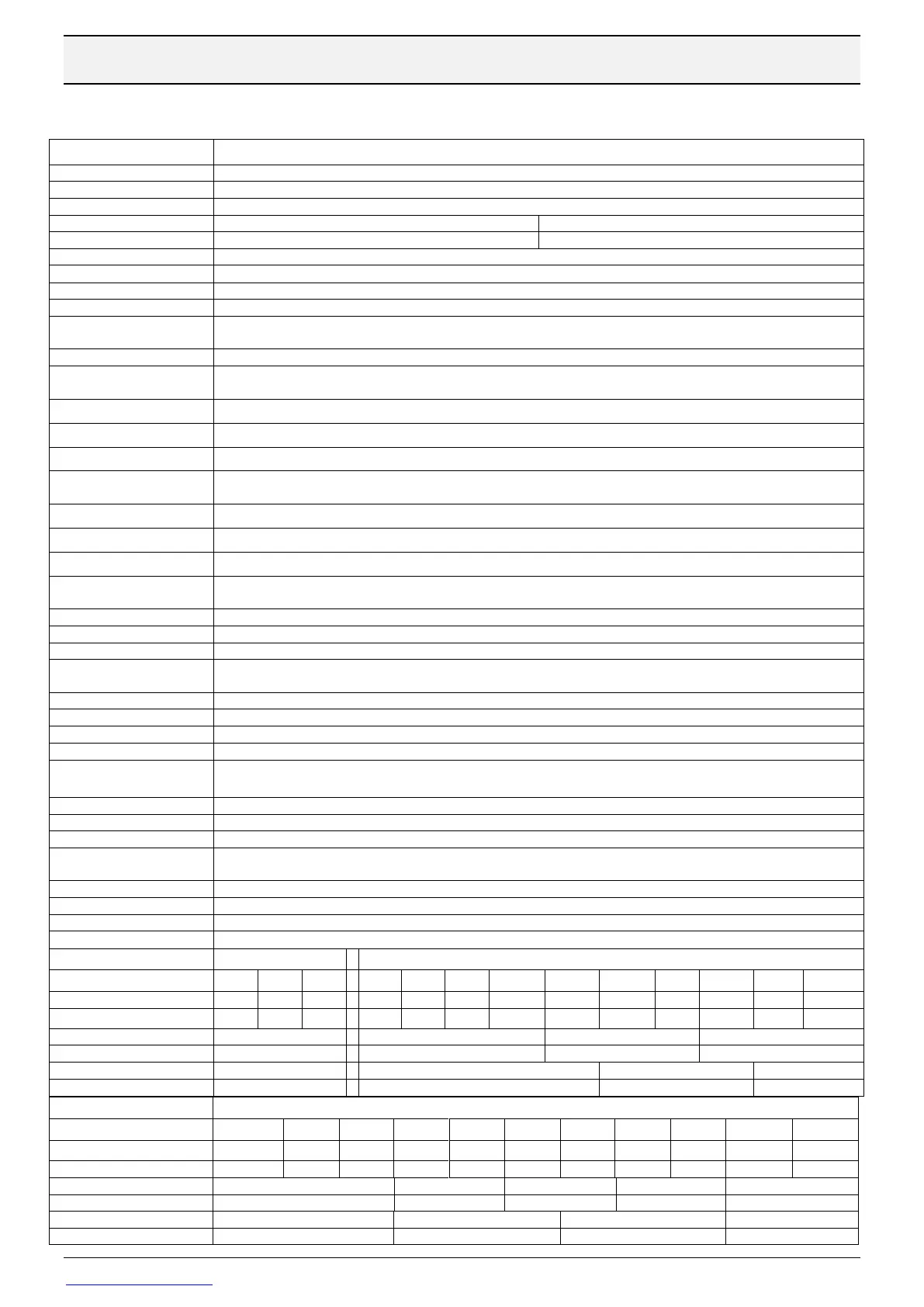

7 General specification

165% of rated current for 4,0 s; 110 % for 1 min

3-fas, 0 V to Supply voltage

Maximum 3 % between phases for full load operation

4, 8, 12, 16, 24 or 32 kHz. Increased switching frequency might decrease output current.

Constant torque, Variable torque, Voltage boost, PM motor support, , Brushless DC motor (BLDCM) support,

Synchronous reluctance motor support, LSPM motors

Digital, Hand/Auto buttons, Keypad, Modbus RTU, Bacnet and Fieldbuses

Digital Preset speed, Digital motor potentiometer, analog 4 – 20 mA, 0 –10 V, Scaling of digital setpoint Keypad,

Modbus RTU, Bacnet, Fieldbuses and Ethernet.

3 x Programmable Digital Input and 2 x User-selectable Digital or Analog Inputs,

2 x User-selectable Digital or Analog Inputs. 4-20 mA or 0-10 V , 12 bits

2 x Programmable Relay (single pole and 2-pole ), Maximum load 6,0 A with 230 V or 5A with 30 VDC.

Drive enabled, Drive healthy, At Target Frequency, Output Frequency ≥ Limit, Output Current ≥ Limit, Analog

Input 2 Level ≥ Limit, Fire Mode Active, Maintenance, Drive Available, Assist Pump 1 Control

2 x User-selectable Digital or Analog Output, 0-10 V DC. Maximum current 20 mA. 10 bits.

Output Frequency, Output motor current or Output motor power.

One with sink logic and one with source output; IEC 61608, IEC 61800-5-2, IEC 62061, ISO 13849

Modbus RTU and BacNet onboard.

Profibus DP, CC-Link, Device Net, Ethernet IP, Modbus TCP, Profinet, Ethercat, Powerlink by option board

0 to 6000 sec, 2:nd deceleration ramp,

Ramping / Fast stop / Coasting / DC-brake Zero speed holding time

Current limit, Input and output loss phase detection, Trip level is resistance >2,5 kOhm

PID-control, Built-in plc, Spin start, Standby mode, Automatic restart, Skip frequency, Stop method at Voltage

interruption, Energy Optimizer, Parameter access lock,

Fire Mode, Stir, Pipe fill protection, Motor preheating, Cascade multi pump, Pump cleaning function

EN60529 : IP20, IP55 or IP66; EN 60721-3-3: IP20: 3S2/3C2; IP55/66: 3S3/3C3

IP20: -10 ºC to +50 ºC , IP55/66: -10 ºC to +40 ºC, Storage temperature is -40 ºC to +60 ºC

No airborne dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and

metallic particles), high moisture, salt or chemical content environments

2000 meter above sea level, Derate above 1000 m: 1 %/100m

IEC 60068-2-29, IEC 60068-2-64, IEC 60068-2-6

IEC 61608, IEC 61800-5-2 (SIL2, PFHd= 1,23E-09 1/h, SFF=50), IEC 62061 (SILCL 2), ISO 13849-1 (PL d)

2014/30/EU

Use shielded motor cable. Built-in EMC-filter, Fulfils Category Class C1, C2, C3 and C4

EN61000-3-12, Fulfilled without the need for Line Reactors 3 for values of R

SCE

> 185

CE, cUL, UL, RoHS, Carbon Trust

Loading...

Loading...