4A1PC-T V2.1 NMV-D2M-EN 11-02-04.doc PM VAV - Subject to technical changes

VAV – Module NMV-D2M

Legend

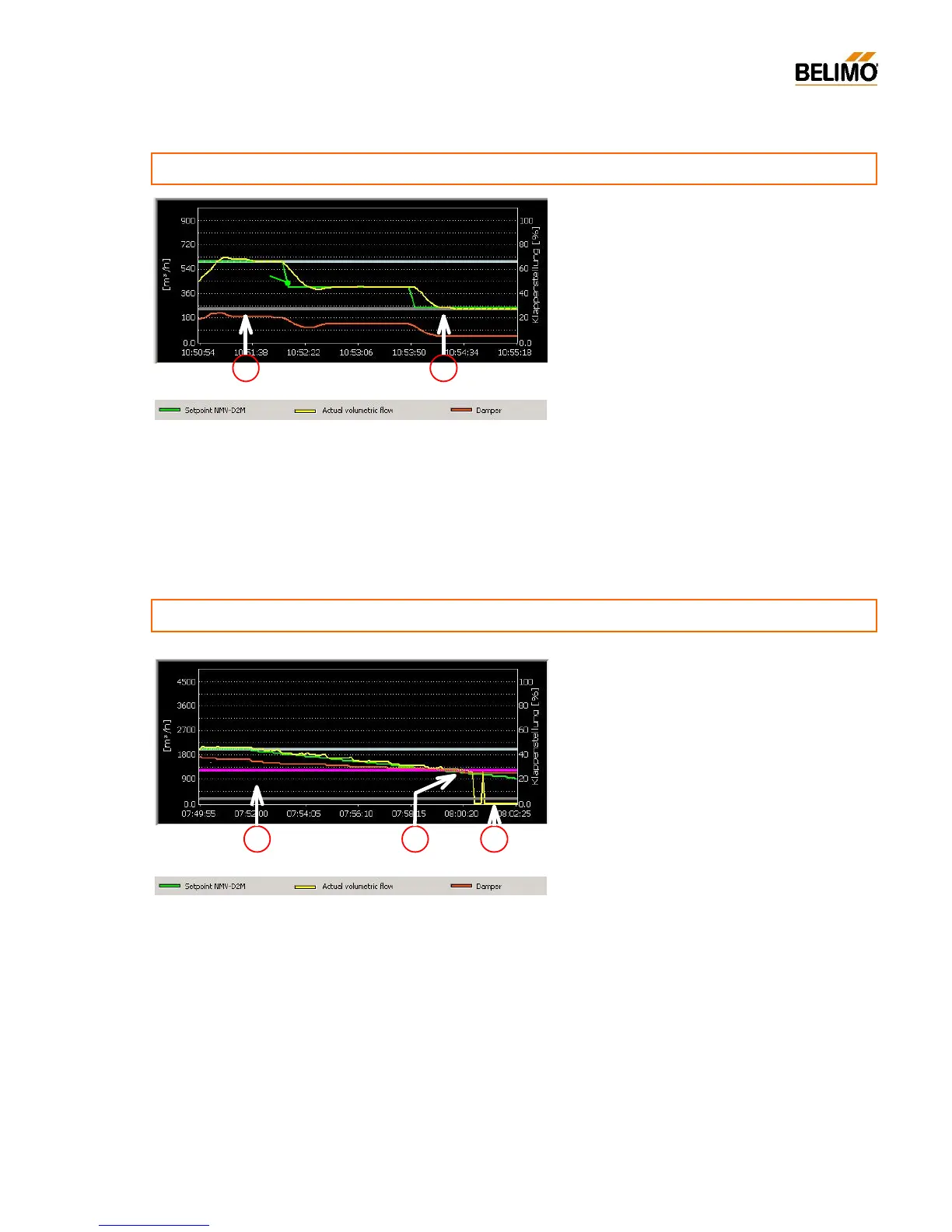

Sequence

a) Step 1: V’max

- Volumetric flow at setpoint

- Damper control range ~42%

b) Step 3: V’min

- Volumetric flow at setpoint

- Damper control range ~28%

.........................................................................

excessive system supply pressure

Suggestion for optimising

Set the fan and pressure control so that the damper

position of the VA-V/ CAV-boxes in V’max opera

approximately 80%

Suitable Test-Sequences

- BasicTest Max-Min 5m.txt

Cause

Fan or pressure control rated too high or set up too

Suggestion for a remedy

- Increase the operating flow rate setting so that the

V’min volumetric flow setting corresponds to an ac-

tive differential pressure setting of more than 2 Pa.

- Investigate changing the air box (smaller nominal

diameter).

.............................................................................................................

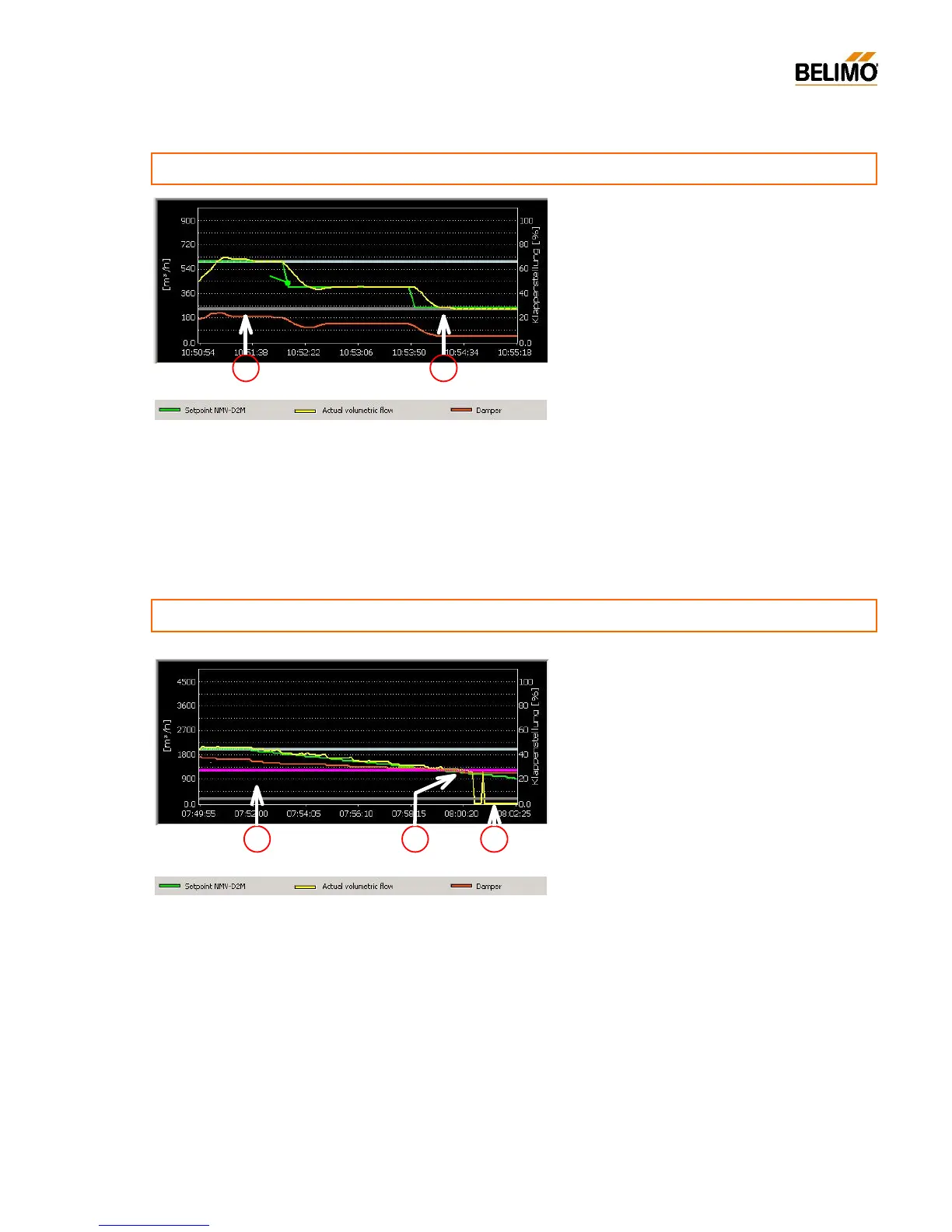

Sequence

a) The setpoint is reduced in 1% steps

b) - Setpoint less than active differential pressure

2 Pa

- NMV-D2M function

Leakage-flow suppression activated

c) - Setpoint less than active differential pressure

2 Pa

- Actual volumetric flow rate = 0

Suitable Test-Sequences

- Test 5 Max-Min-Max [1%] 37m.txt

- Test 4 Max-Mid-Min 9m.txt

Note:

If the system does not attain the required supply pressure – during the

Test start – the Test-Sequence is discontinued and the fault alarm ‘In-

adequate supply air pressure’ is given.

See:

- Air box manufacturer’s documentation on minimum air flow for the VAV-/CAV-

box

- section ‘N-S1.2.1 Control range’

Causes and consequences

- VAV-/CAV-box oversized for the required value of

volumetric flow

- Oversized air boxes are being operated in a difficult-

to-control, sometimes uncontrollable, range

- The function range of the VAV-/CAV-box must not

exceed 2 Pa. Otherwise the air box will be operated

near leakage-flow suppression, i.e. in the uncontrol-

lable range.

a

NMV-D2M – Diagnosis

Legend

Loading...

Loading...