26

with the cutting table 26 (the lines "close" on scale will coincide). To do so, unscrew the

flywheels 6, lift the lever-stick 4 and 5 (Fig. E), and then tighten the flywheels again 6. The

locking clip 52 will automatically block the planing tables 2 and 3.

11.2.2 Installing the cutting depth

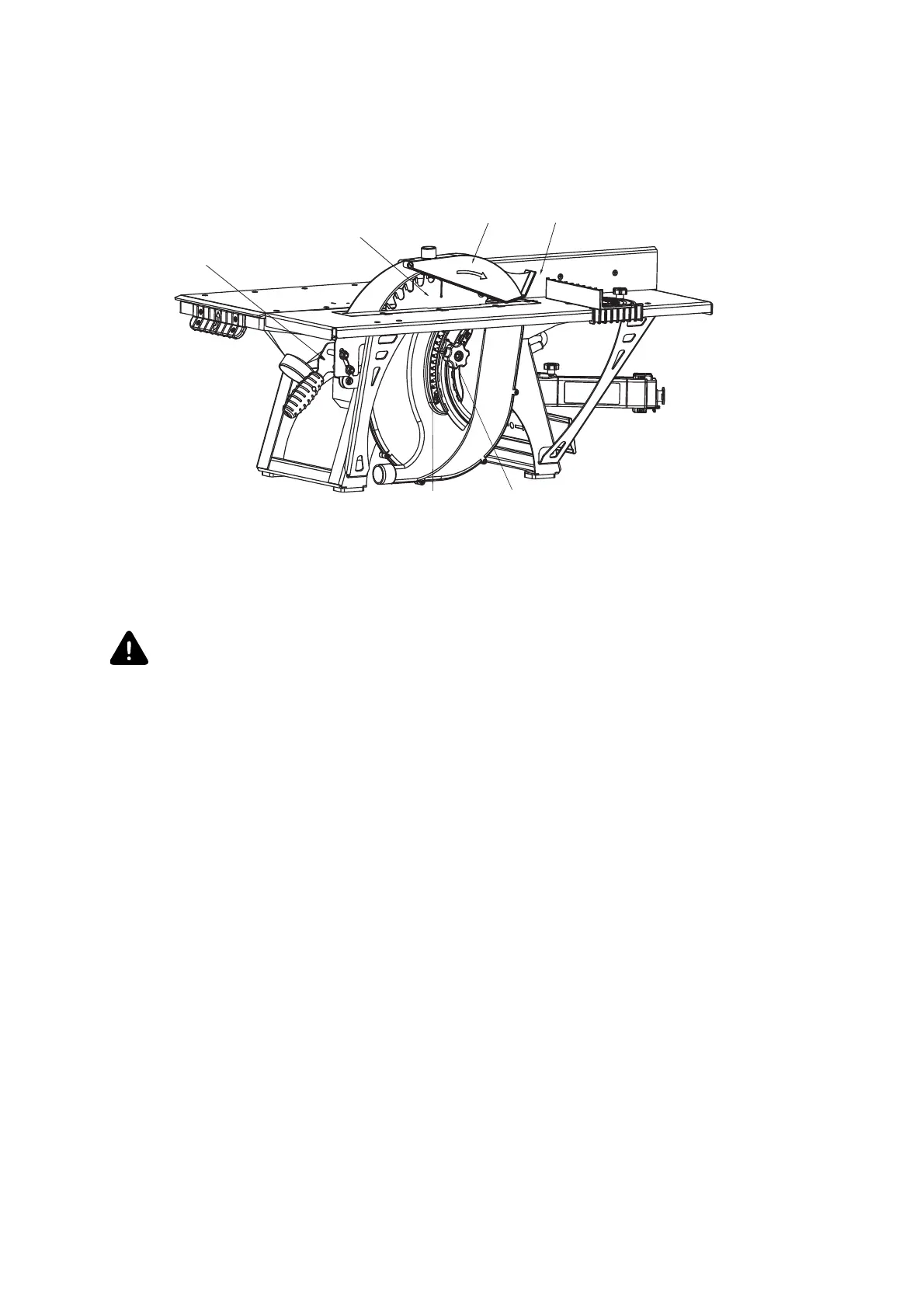

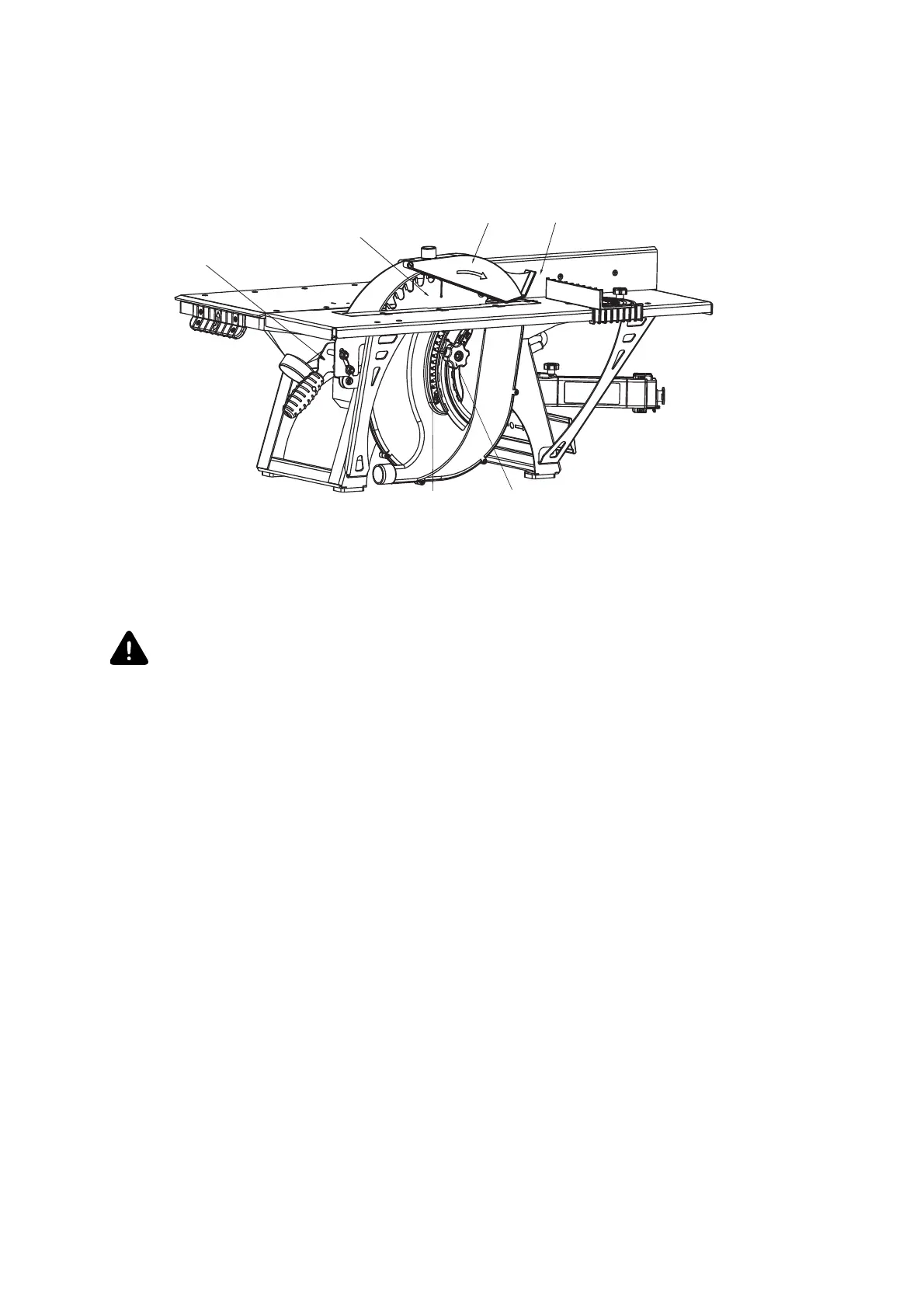

Fig. S

Installing the cutting depth

12 – ruler of the angular bum; 25 – saw blade; 27 – lever for lifting and lowering the saw blade; 29 – fencing of saw

blade; 32 – flywheel for saw blade/cutter disc fixation; 37 – cutting depth scale

Cutting depth installation is performed only when the cutting and planing tables are

brought together and set to the same level.

Adjusting the cutting depth is made with the help of the lever 27 by moving it up/down, after

releasing the flywheel 32. The depth of cutting is set on the scale 37 and fixed by the flywheel

32.

11.3 Longitudinal angular cutting with the use of a ruler

The ruler 12 with an angular bump 11 (Fig. Q, S) is fixed to the planing loading table with the help

of the flywheels.

The distance between the saw blade and the ruler can be measured by moving the lower part

of the angular bump in slots and moving the holes 2a of the loading table 2. Thus, you can

set any cutting width.

The ruler is installed both perpendicularly to the table and angularly (p. 11.1.4) and should fit

to the table at any rotating angle.

11.4 Angular cross cutting with the use of device

To install the device, it is necessary to set the slide 33 (Fig. T) through the open edge of the

table so that the hoop on the bottom covered the leading edge 5 of the cutting table.

The bump 34 can be rotated relative to the slide 33, setting and fixing it perpendicularly to

the cut of the saw blade or angularly (–45° to +45°) to make the beveling cut. Install the

desired cutting angle, rotating the bump 34 and fixing it by the flywheel 36. Pressing the

27

25

32

29 12

37

Loading...

Loading...