30

the fencing is adjusted by moving the horizontal rod 42 along the vertical rod 41.

11.6.3 Adjusting the milling depth

The milling depth of the disc cutter is installed similarly as in the case of saw blade (p. 11.2.2).

The milling depth scale 38 is located from the right side of the casing 30 of the saw blade

(Fig. B).

12. MAINTENANCE AND REPAIR

In order to maintain the machine in a permanent technical efficient and working condition, it

is necessary to service the machine each time before using it. It includes the following:

Performing exterior check;

Checking the fixing security of slicing blades;

Cleaning the machine.

The exterior check includes cable test, integrity of security fencing test.

Checking the fixing security of slicing blades is performed by tightening the screws 71 with

the wrench (Fig.К).

Cleaning includes removing dust, cuttings, wood particles with a brush or a vacuum cleaner

from the machine surface.

12.1 Replacing the slicing blades

Periodically, it is required to resharpen or replace the slicing blades, whenever they has dulled

noticeably (Fig. Y).

The cutting edge of the blade should be sharp and clean. There should not be any notches,

rough guide lines and cracks.

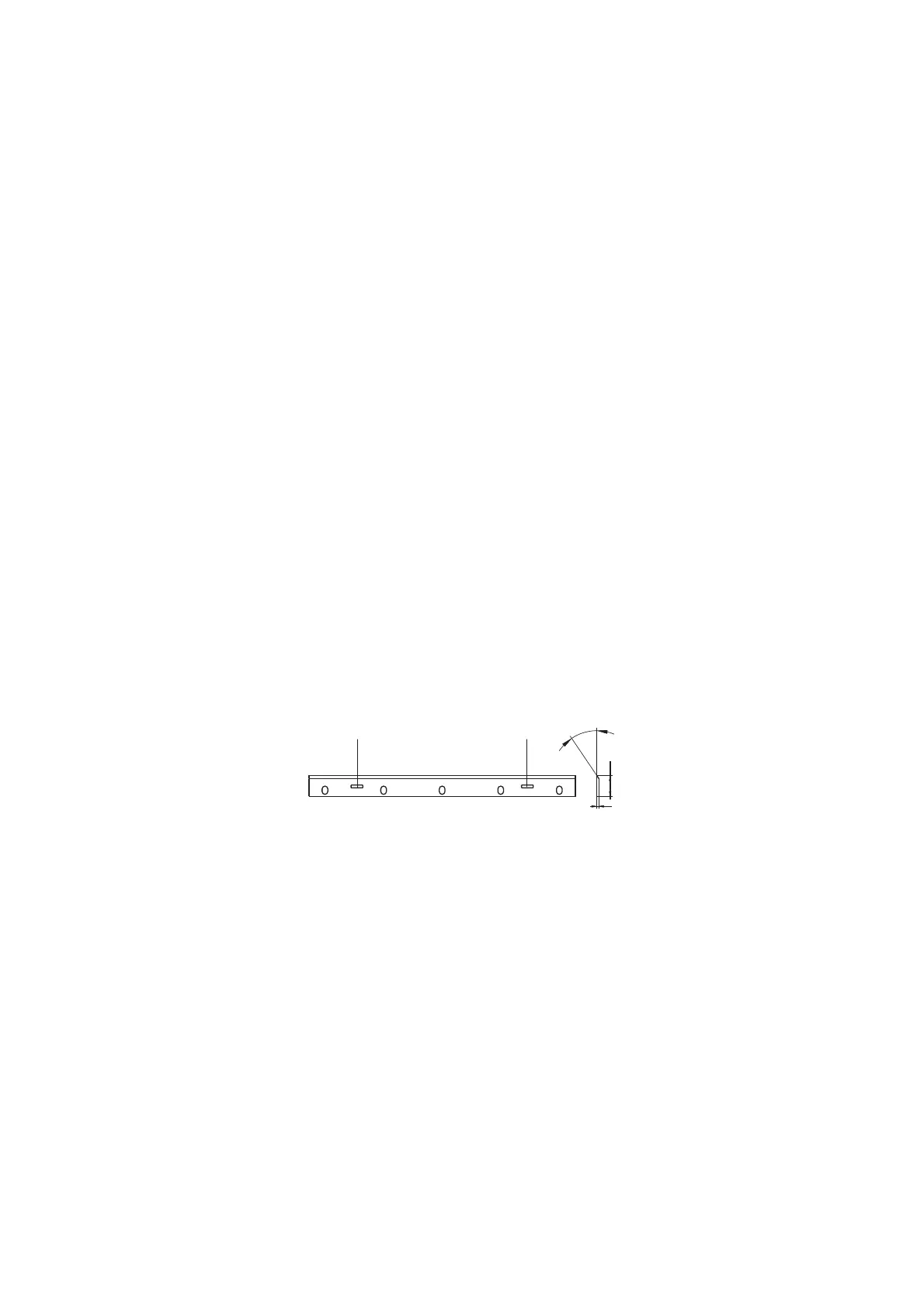

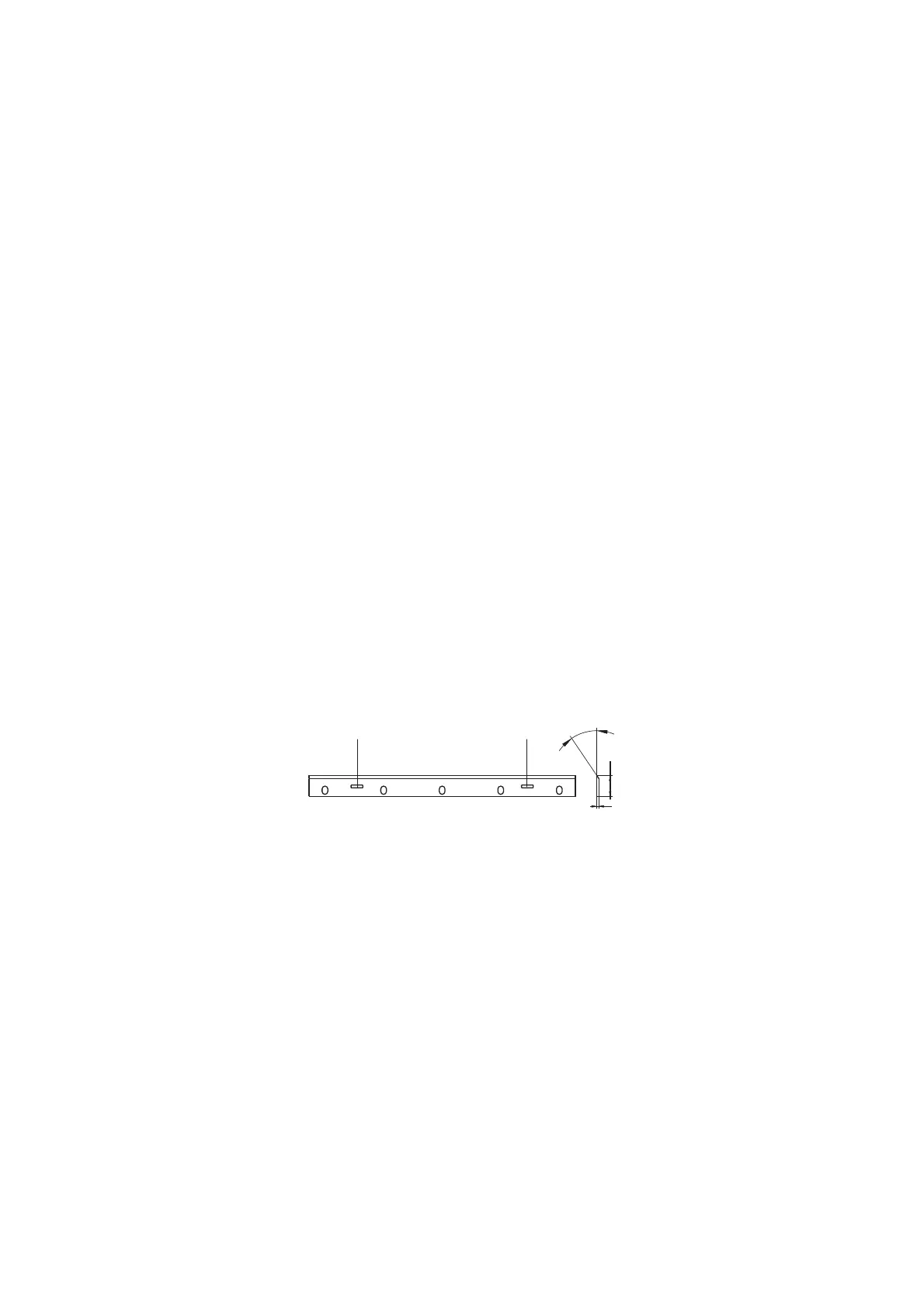

Fig. Y

Slicing blade

70a – slot

To the replace the knives, it is necessary to perform the following action:

remover the holder 69, by loosening the crews 71 (Fig. K);

replace the knife 70, installing it so that, the knife slots 70a fit the flags 73 (Fig. M);

install the holder 69 and fix it with the screws 71.

When installing the new blades, replacing fixing parts, and after resharpening, the difference

of the total mass of the knife kit with the fixing parts should not exceed 1 gram.

Adjust the knives as it is described in the paragraph 10.3.

70а 70а

40°± 5°

20

2

Loading...

Loading...