27

workpiece to the bump 34, move the device along the guideway 26a in the direction of the

saw blade.

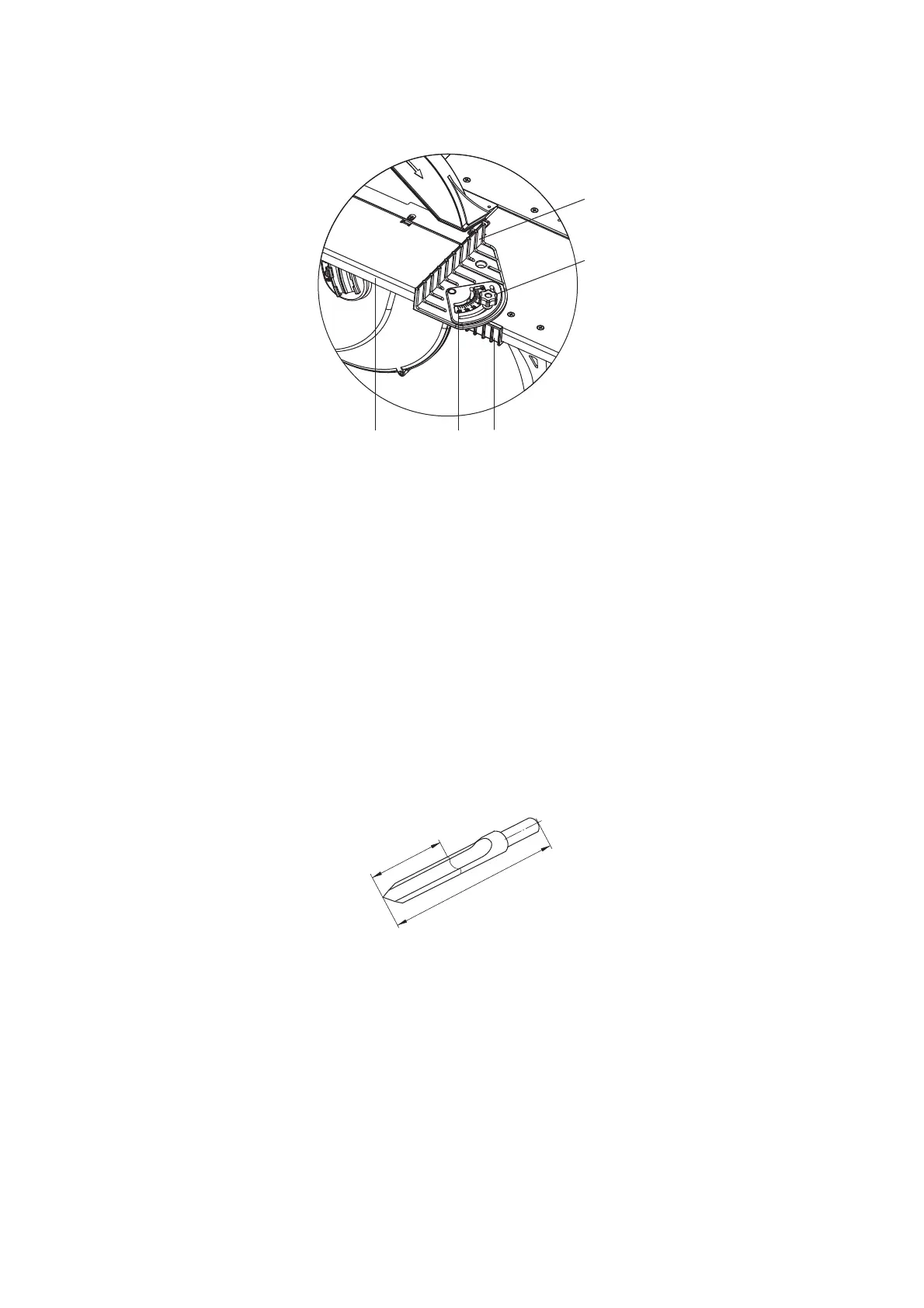

Fig. Т

The device construction for angular cross cutting

26а – leading edge; 33 – bump slide; 34 – bump; 35 – scale; 36 – flywheel for bump fixation

11.5 Milling with end cutters/drilling

Before starting, it is recommended to make the following adjustments:

To bring together the loading 2 and outfeed planing 3 tables, install them on the same

level with the cutting table 26 as described in the paragraph 11.2.1;

To lower the saw blade 25 to the lower position «min» on the cutting depth scale 37;

To install the cutting tool;

To adjust the table;

To install the ruler 12 with the angular bump 11.

11.5.1 Installing the end mill cutter/drill

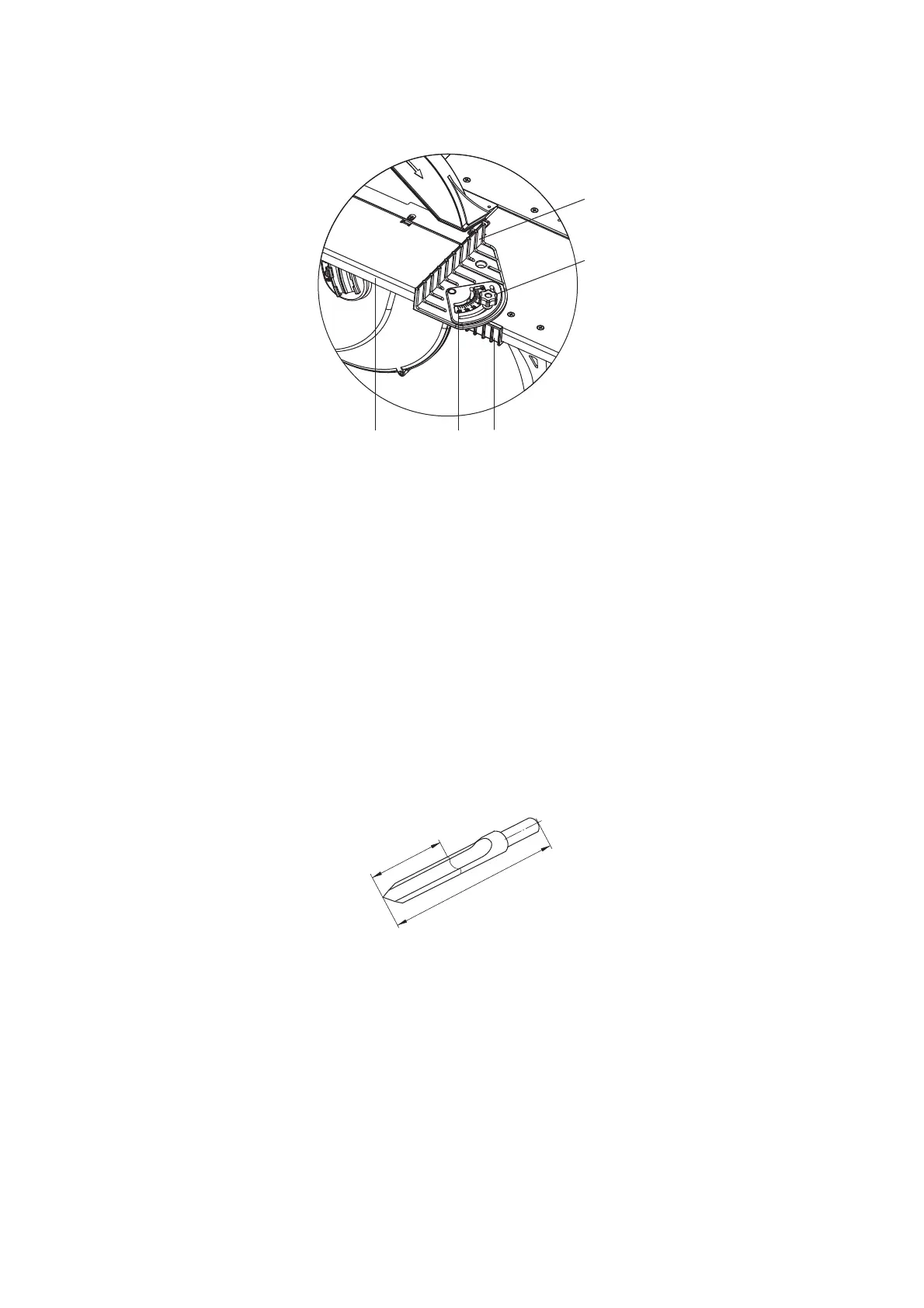

End mill cutters are used as a cutting tool as shown in the Fig. U.

Fig. U

End mill cutter

To install end mill cutter/drill, it is required to perform the following:

To remove knife’s block fencing 65 (Fig. Е);

To install the drill chuck 55(Fig. V) on the cutting surface of the knife block end;

To install and fix the end cutter47 or drill to the drill chuck 55;

To install fencing 51 of the end cutter 47 and fix it with screws 64.

The end mill cutter fencing has a sprung security cap 51a, which moves into the casing when

pressing the workpiece on the cap in the axial direction, opening the working part of the end

mill 47.

26а 35

34

36

33

40 mm

70 mm

Loading...

Loading...