1818

STEP 4

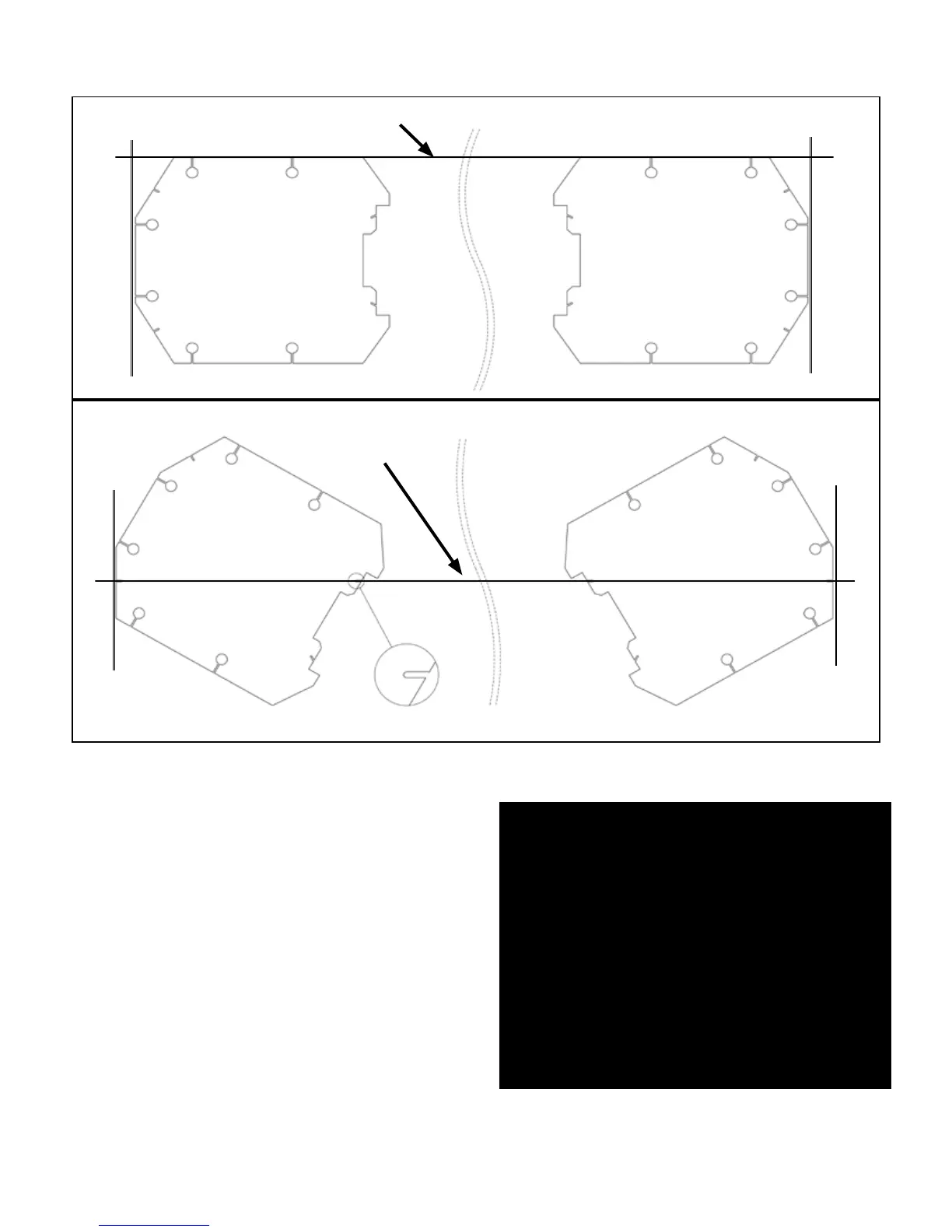

(Site Layout)

1. Determine which side of the lift will be the approach side.

2. Now determine where the power unit will be located.

The POWER SIDE column has the power unit mounting

bracket attached to the side.

3. Use the chart on page 12 to determine which lift width

layout you would like to use. Also, you can see image above

for reference.

4. Once a location is determined, use a carpenter’s chalk

line to layout an alignment line for the post locations. Keep

all dimensions square within 1/8” (3mm) or malfunction of

the lift can occur. (See Fig 4.1)

5. After the post locations are properly marked, use chalk

or crayon to make an outline of the posts on the oor at each

post location using the post base plates as a template.

6. CHECK ALL DIMENSIONS TWICE and make sure that

the layout is perfectly square.

STEP 5

(Installing the POWER SIDE post)

1. Before proceeding, double check measurements and

make certain that the base plate of each post is aligned

with the chalk line.

CHALK LINE

CHALK LINE

FOR XPR-10AS CONFIGURATIONS USE NOTCHES TO ALIGN POSTS.

FOR XPR-10S CONFIGURATIONS USE BASE PLATE EDGES TO ALIGN POSTS.

NOTE:

BENDPAK LIFTS ARE SUPPLIED WITH

INSTALLATION INSTRUCTIONS AND CONCRETE

FASTENERS MEETING THE CRITERIA AS

PRESCRIBED BY THE AMERICAN NATIONAL

STANDARD "AUTOMOTIVE LIFTS - SAFETY

REQUIREMENTS FOR CONSTRUCTION, TESTING,

AND VALIDATION" ANSI/ALI ALCTV-2011. LIFT

BUYERS ARE RESPONSIBLE FOR ANY SPECIAL

REGIONAL STRUCTURAL AND/OR SEISMIC

ANCHORING REQUIREMENTS SPECIFIED BY ANY

OTHER AGENCIES AND/OR CODES SUCH AS THE

UNIFORM BUILDING CODE (UBC) AND/OR

INTERNATIONAL BUILDING CODE (IBC).

OUTSIDE

BASEPLATE

OUTSIDE

BASEPLATE

OUTSIDE

BASEPLATE

OUTSIDE

BASEPLATE

Fig 4.1

Loading...

Loading...