20

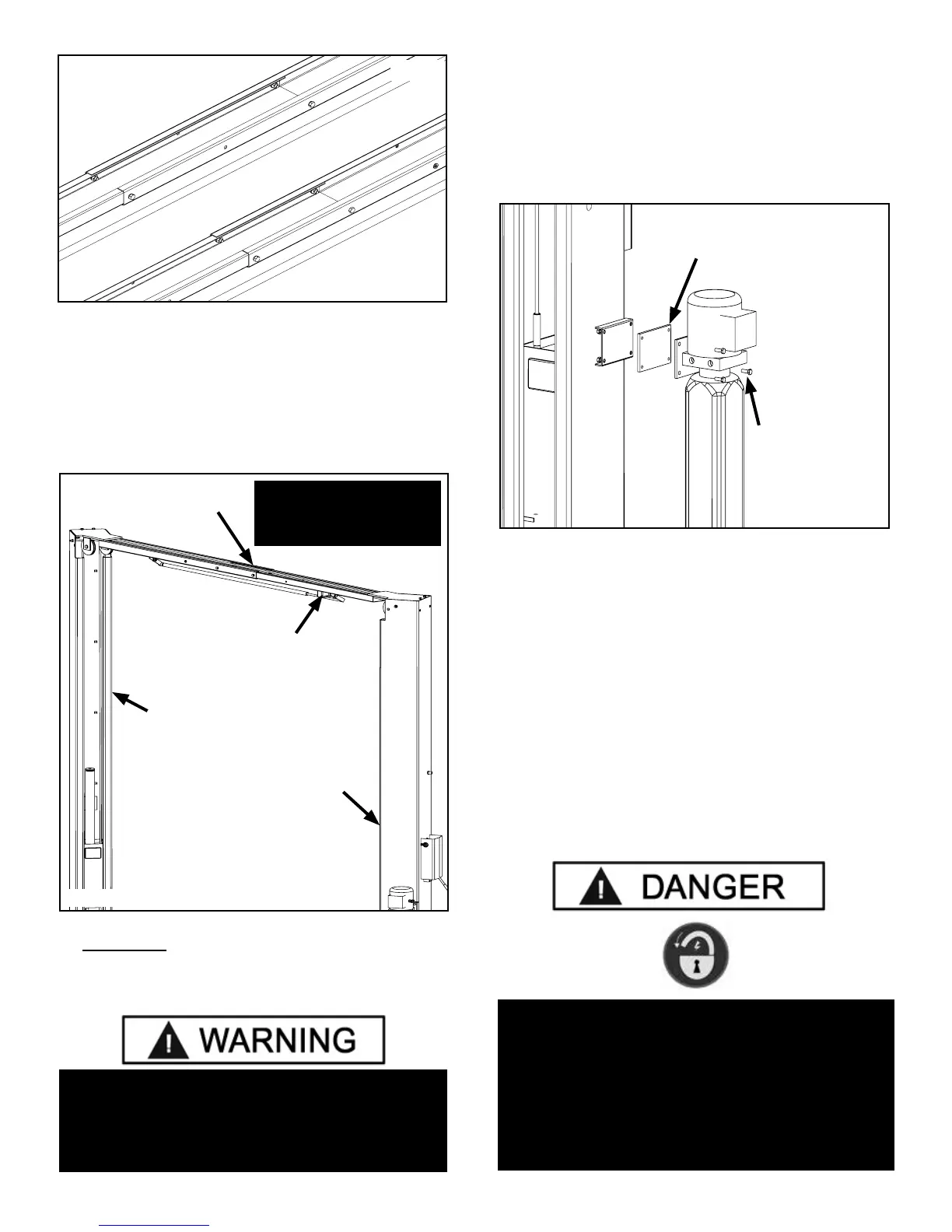

2. Adjust the Overhead Assembly width to match either

the Narrow or Wide conguration, and loosely tighten bolts.

(See Fig 7.1)

3. Using a lifting device, raise the Overhead Assembly

into position on top of the posts. Bolt Overhead Assembly

to the posts using the provided M10 hex head bolts, nuts

and washers.

4. YOU MUST POSITION THE SWITCH ENCLOSURE

ADJACENT TO POWER SIDE POST. (See Fig. 7.2)

5. Tighten the Overhead Assembly bolts.

STEP 8

(Mounting the Hydraulic Power Unit)

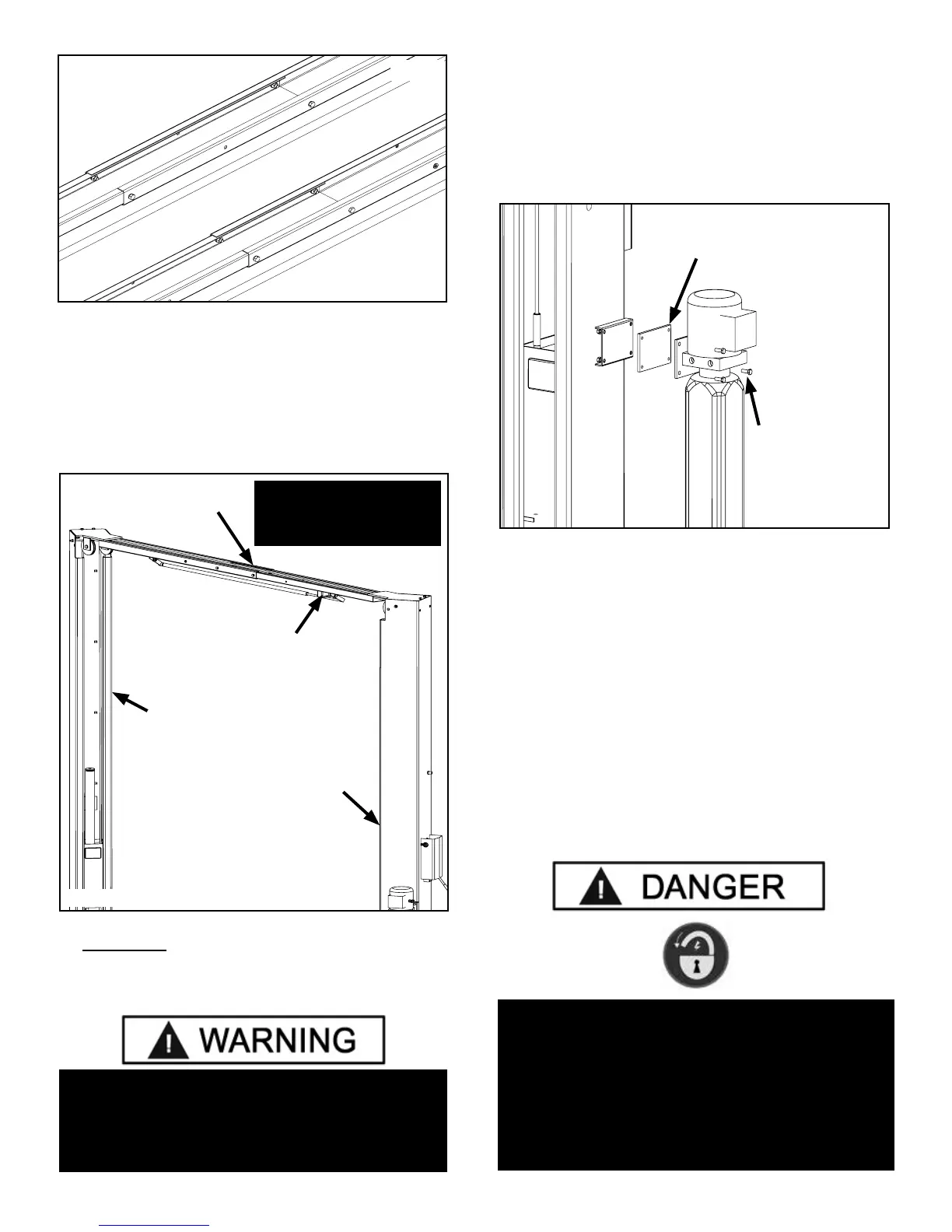

1. Attach the power unit to the POWER SIDE post. Install

the vibration dampener between the power unit and the

power unit mounting plate on the Power Side post, using

four M8 hex head bolts and nuts supplied. (See Fig 8.1)

2. Fill the reservoir with 10 WT. HYDRAULIC OR

APPROVED ATF FLUIDS SUCH AS DEXRON III,

DEXRON VI, MERCON V, OR MERCON LV (another

option ISO-32 grade) approximately four gallons. Make

sure the funnel used to ll the Power Unit is clean. Do

not connect power unit hydraulic hose assembly at this

time.

3. The standard power unit for your lift is 220 volt, 60HZ,

single phase. All wiring must be performed by a certied

electrician only. SEE WIRING INSTRUCTIONS AFFIXED

TO MOTOR FOR PROPER WIRING INFORMATION.

STEP 9

(Installing the Safeties and Safety Cable)

20

IF THE ANCHOR BOLTS WERE LOOSENED TO AID

ON THE INSTALLATION OF THE TOP TROUGH,

TIGHTEN ANCHOR BOLTS AS INDICATED

IN STEP 5 ITEMS 4 - 7.

Fig 7.1

Narrow Conguration

Wide Conguration

Fig 7.2

Off Side Post

Power Side Post

Overhead Assembly

Microswitch Bracket

Fig 8.1

Vibration Dampener

M8 x1.25 x 35mm

hex head bolts, M8

at washers and

M8 Nylock nuts

(Qty 4 ea.)

Position Overhead Assembly

with microswitch bracket

adjacent to Power Side post.

DO NOT PERFORM ANY MAINTENANCE OR

INSTALLATION OF ANY COMPONENTS

WITHOUT FIRST ENSURING THAT ELECTRICAL

POWER HAS BEEN DISCONNECTED AT

THE SOURCE OR PANEL AND CANNOT BE

RE-ENERGIZED UNTIL ALL MAINTENANCE

AND/OR INSTALLATION

PROCEDURES ARE COMPLETED.

Loading...

Loading...