31 Bentone

Suction line tables

The suction line tables consist of theoretically calculated

values where the pipe dimensions and oil velocity have

been matched so that turbulences will not occur. Such

turbulences will result in increased pressure losses

and in acoustic noise in the pipe system. In addition to

drawn copper piping a pipe system usually comprises

4 elbows, a non-return valve, a cut-off valve and an

external oil filter.

The sum of these individual resistances is so insignificant

that they can be disregarded. The tables do not include

any lengths exceeding 100 m as experience shows that

longer lengths are not needed.

The tables apply to a standard fuel oil of normal

commercial quality according to current standards. On

commis sioning with an empty tube system the oil pump

should not be run without oil for more than 5 min. (a

condition is that the pump is being lubricated during

operation).

The tables state the total suction line length in metres at

a nozzle capacity of 2,5 kg/h. Max. permissible pressure

at the suction and pressure side is 2,0 bar.

Purging

On 1-pipe systems it is necessary to purge the pump.

On 2-pipe systems purging is automatic through the

return line.

1.1.1 Suction line tables

1.1.1.1 Overlying tank

1-pipe system

0 90 75 56 45

0,5 100 83 63 50

1 110 92 69 55

2 131 109 82 65

3 152 126 95 76

4 172 144 108 86

30 150 22 113 11 56 150 7 37 119 4 23 74 150

33 150 25 126 12 63 150 8 41 133 4 26 83 150

37 150 27 139 13 69 150 8 46 146 5 28 92 150

44 150 33 166 16 82 150 10 55 150 6 34 109 150

50 150 38 192 18 96 150 12 63 150 7 39 127 150

57 150 43 218 21 109 150 14 72 150 8 45 144 150

d (mm)

Nozzle*/Düse*

Gicleur*/Ugello*

(US GPH)

0,50 0,60 0,80 1,00 1,50 2,00 4,00 6,00 9,50

H (m)

4 4 4 4 4 6 4 6 4 6 8 4684 6 8 10

*A2L pumps : sum up the 2 nozzles / A2L-Pumpen : Summe der zwei Düsen

pompe A2L : somme des 2 gicleurs / Per le pompe A2L aggiungere n.2 ugelli

Two-pipe system

0 2 15 50 124

0,5 2 16 56 138

1 2 18 61 150

2 3 22 73 150

3 4 26 85 150

4 4 30 97 150

11 38 96 150 7 27 71 150 20 54 116 150 16 46 100 150

12 42 107 150 8 31 79 150 23 61 130 150 19 52 112 150

13 47 118 150 9 34 88 150 26 68 144 150 21 57 124 150

16 56 141 150 11 41 105 150 31 81 150 150 26 69 148 150

19 66 150 150 13 48 122 150 36 94 150 150 31 81 150 150

22 75 150 150 16 55 139 150 42 108 150 150 35 92 150 150

d (mm)

35/45 55 65 75 95

60 77 102 130 150

Pump/Pumpe

Pompe/Pompa

Q** (l/h)

4 6 8 10 6 8 10 12 6 8 10 12 8 10 12 14 8 10 12 14

H (m)

**Q = pump capacity @ 0 bar / Pumpenleistung bei 0 bar

capacité de l'engrenage à 0 bar/portata della pompa a 0 bar.

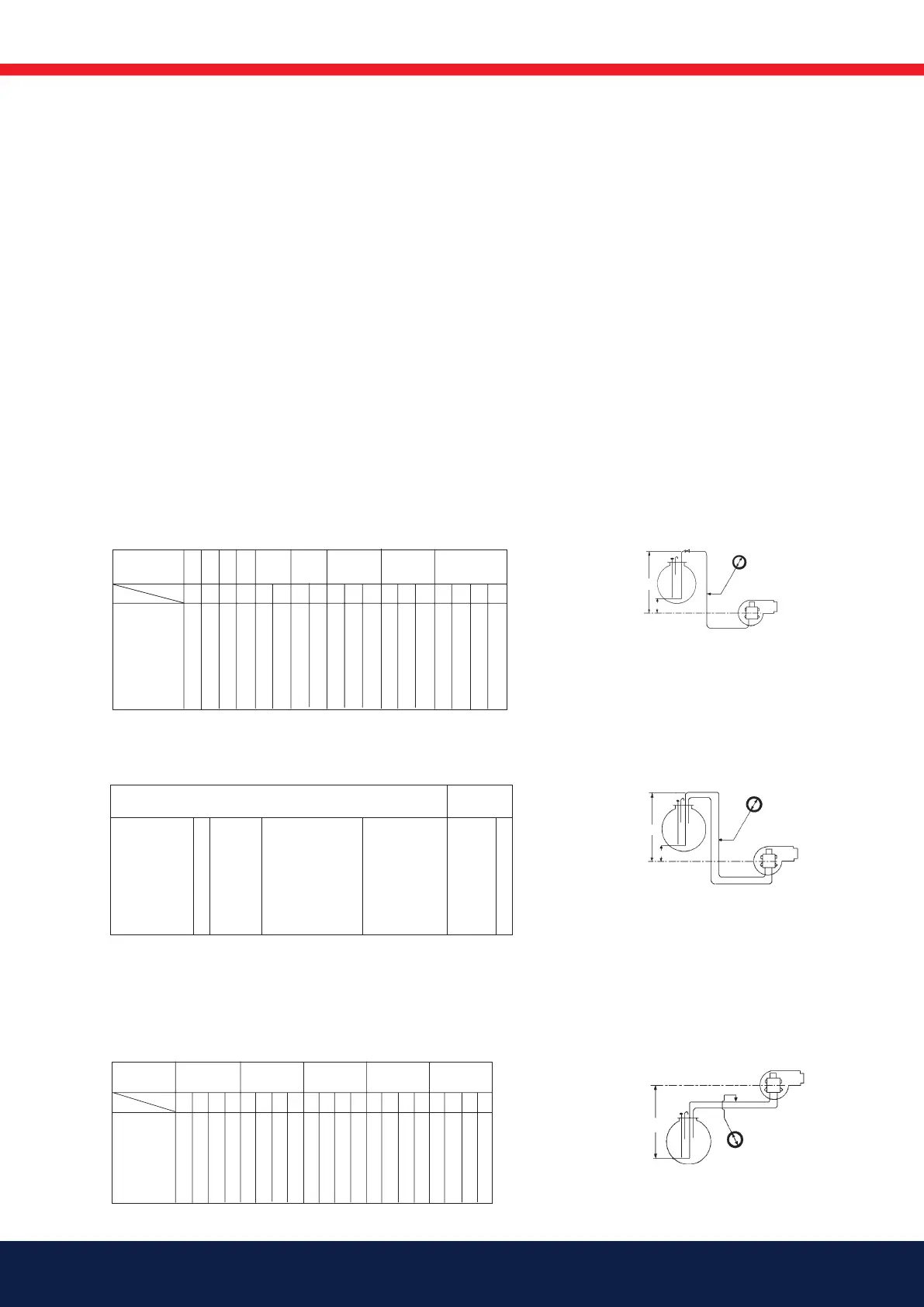

One pipe siphon feed system

Einstranginstallation - Tank höher als Pumpe

Installation monotube en charge

Impianti monotubo a sifone

E

d

E max. = 20 m

(E-H) max. = 4,5 m

H

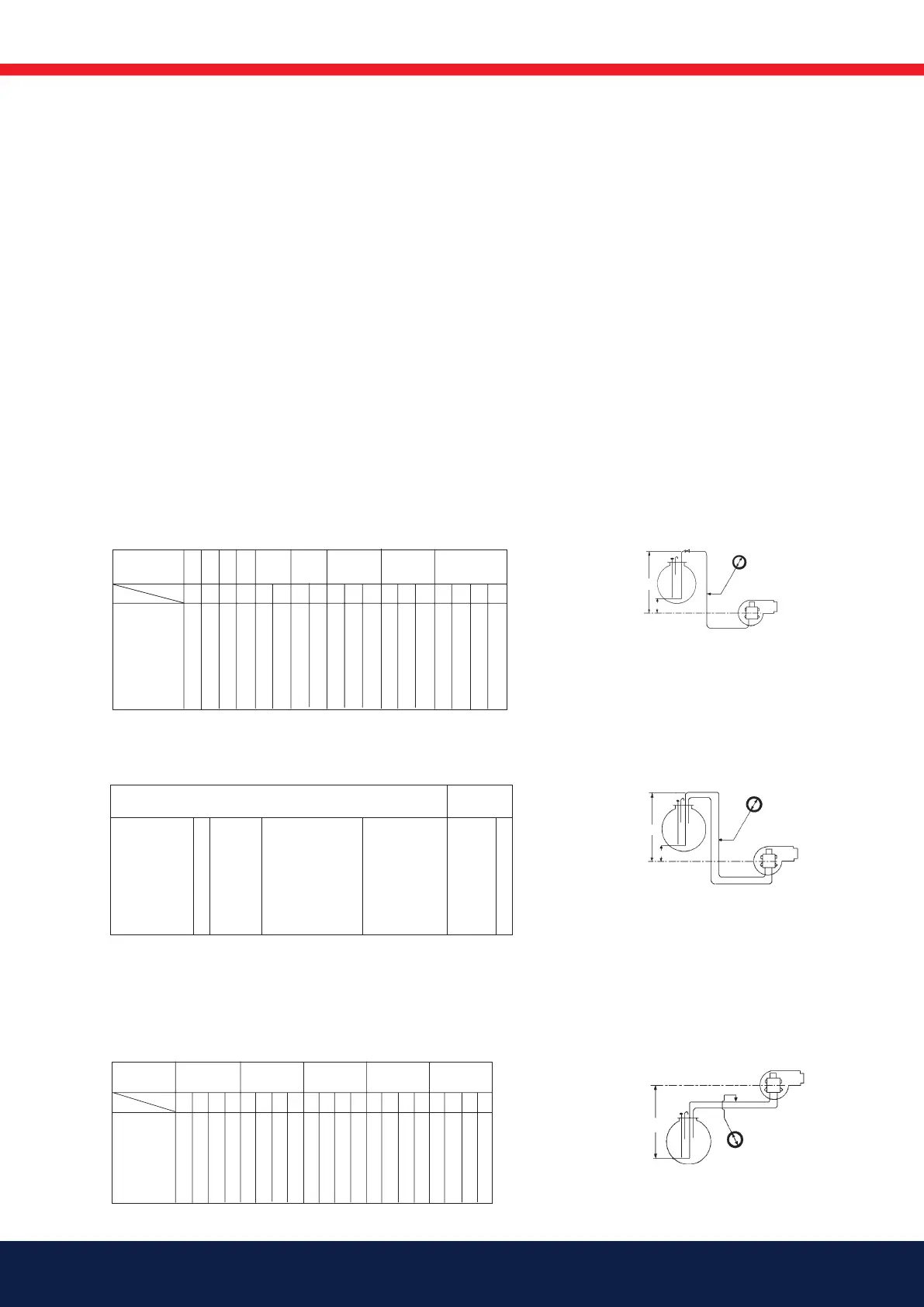

Two pipe siphon feed system

Zweistranginstallation - Tank höher als Pumpe

Installation bitube en charge

Impianti bitubo a sifone

D

H

D max. = 20 m

(D-H) max. = 4,5 m

d

1.1.1.1 Underlying tank

1-pipe system

With an underlying tank a 1-pipe-system is not recommended

Two-pipe system

0 15 50 124 150

0,5 13 44 109 150

1 11 38 95 150

2 7 26 66 138

3 3 14 37 79

84 19

11 38 96 150 7 27 71 150 20 54 116 150 16 46 100 150

9 33 84 150 6 24 62 132 17 48 103 150 14 40 88 150

8 29 73 150 4 20 54 115 15 41 89 150 12 34 76 144

5 19 51 107 2 13 37 80 9 28 61 116 7 23 52 100

10 28 60 6 20 44 4 14 33 65 11 28 55

5 14 9 6 14 4 11

d (mm)

35/45 55 65 75 95

60 77 102 130 150

Pump/Pumpe

Pompe/Pompa

Q** (l/h)

6 8 10 12 6 8 10 12 6 8 10 12 8 10 12 14 8 10 12 14

H (m)

Two pipe lift system

Zweistranginstallation - Tank tiefer als Pumpe

Installation bitube en aspiration

Impianti bitubo in aspirazione

H

H max. = 4,5 m

d

Loading...

Loading...