7

caldaie

Solenoid valves

Modulator

that gas flowing to the burner is stopped very quickly under

any faulty condition.

The modulator is an integral part of the gas valve; the operator

modulates by changing the current to the coil to let the right

quantity of gas to flow to the burner (Sect. 1.5.1 page 3).

1.5.18 Safety valve

(POS. 16 APPENDIX - A page 77)

The safety valve is located underneath the circulator (Sect. 1.5.3

page 3) and has the job of protecting water circulation from

eventual over pressure caused, for example, by an increase in

the volume of primary fluid due to heating effect. The valve is

gauged to an operating pressure of 3 bar.

1.5.19 Expansion tank (POS. 17 APPENDIX - A page 77)

The expansion tank is located between the two uprights of the

framework and has the job of compensating the increased

volume of primary fluid from heating effect, thanks to the work

done by a rubber membrane loaded with nitrogen beforehand

at 1 bar.

It has been scaled to meet with all engineering solutions

normally used in domestic central heating units. The current

production expansion tank has a capacity of 8 l. and is adequate

for a system containing about 100 l. It may eventually be

integrated with an auxiliary if it should prove to be insufficient.

1.5.20 Fan (C.S.I. only)

(POS. 18 APPENDIX - A page 77)

The fan is located above the combustion chamber (Sect. 1.5.2

page 3) and serves to expel combustion products from the air

box (Sect. 1.5.11 page 5).

Specifically designed for this kind of application, it has the

characteristic of being absolutely silent with top performance.

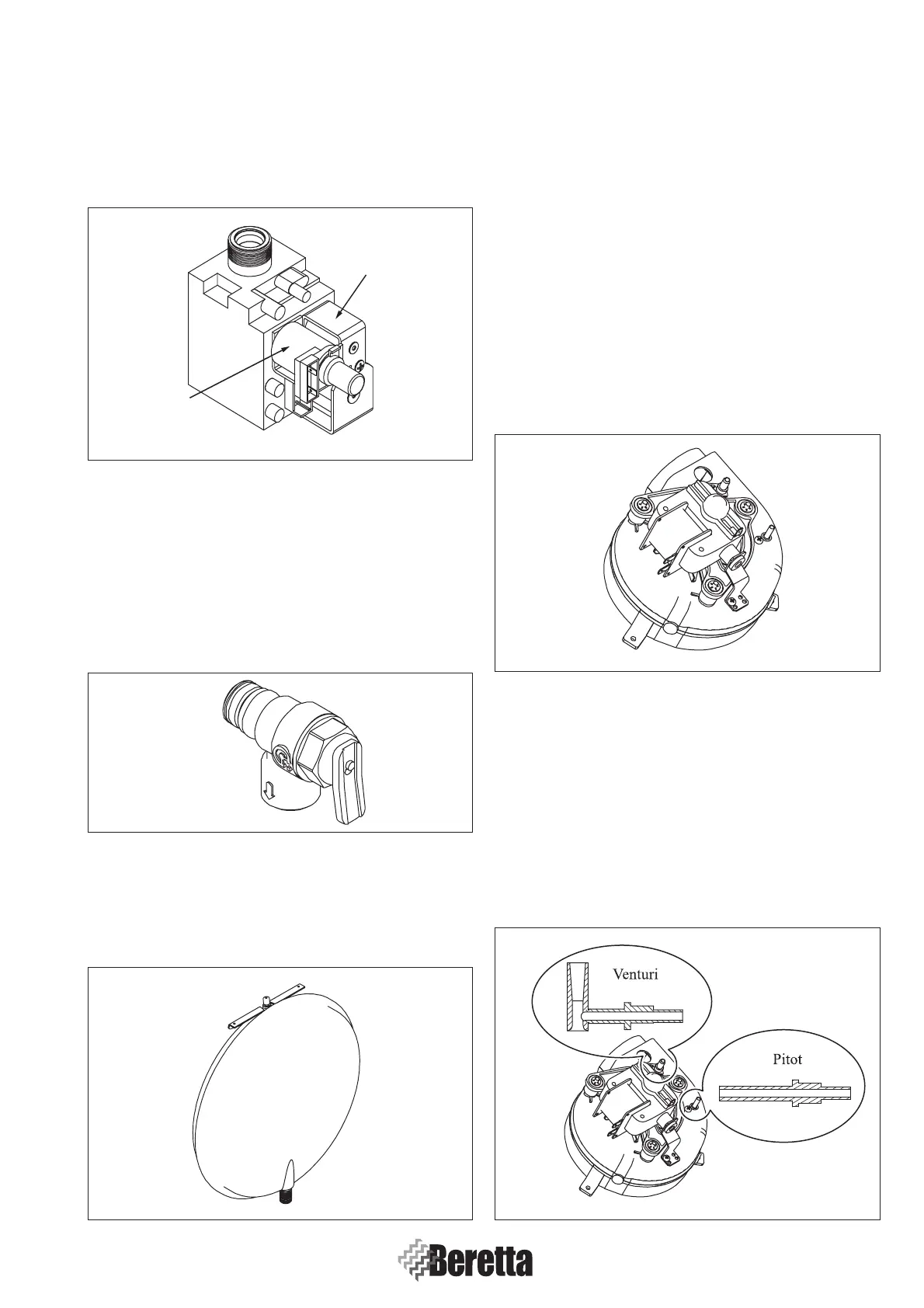

1.5.21 Venturi and Pitot tube (C.S.I. only)

(POS. 19 APPENDIX - A page 77)

The Venturi and Pitot tube are installed on the fan screw conveyor

(Sect. 1.5.20 page 7) and continuouslycorrect scavenging of

products of combustion.

The first device has the job of signalling static pressure value

as combusted gas flows through, while the second measures

the total pressure. The difference in pressure works on the safety

pressure switch membrane (Sect. 1.5.8 page 4), through two

small tubes, switching on the microswitch.

Fig. 1.19

Fig. 1.20

Fig. 1.21

Fig. 1.22

Fig. 1.18

Loading...

Loading...