18

8. Turn the screw marked “20 mA” so that it reads 20 mA on

the milliammeter.

9. Come back to the closed position and check that for the 0%

position, the signal current shows a value close to 0/4 mA

and repeatable.

5.6 Calibration of positioner (OPTION)

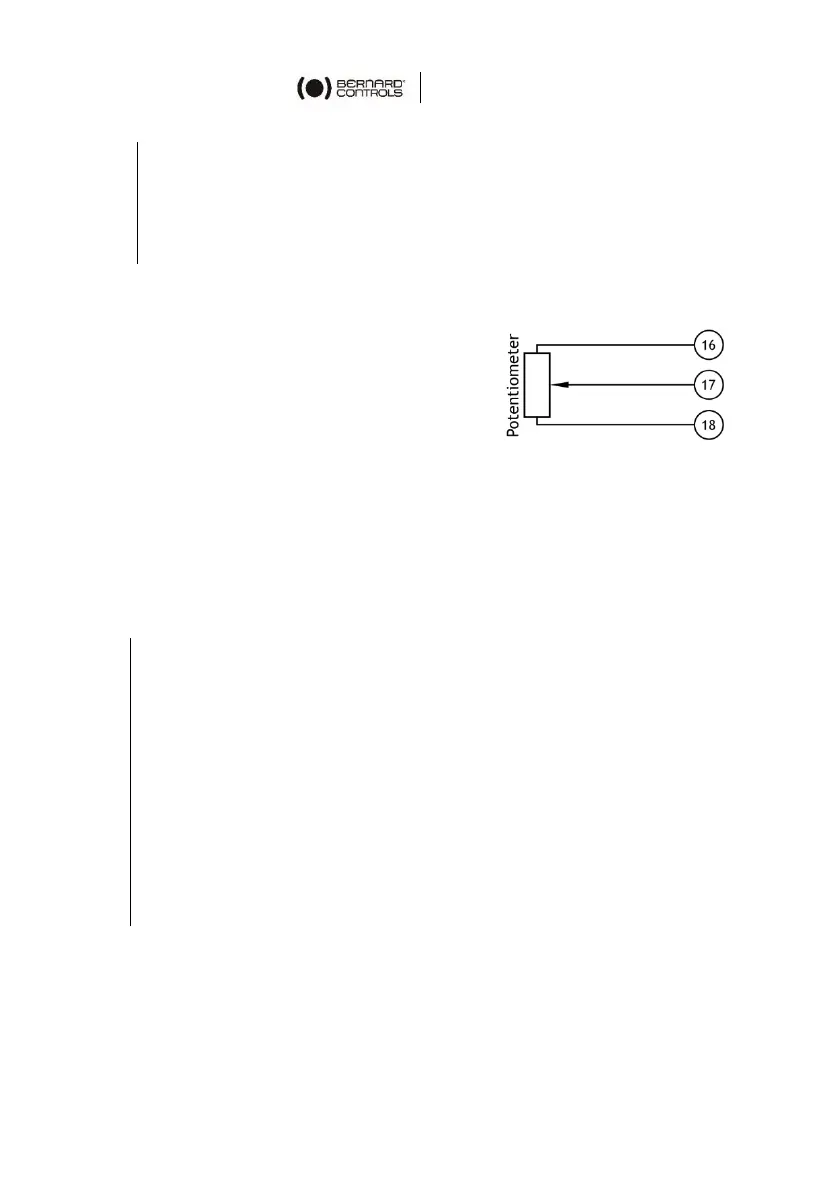

The potentiometer used for actuator

signal feedback is driven by the position

indicator rod.

For clockwise closing:

• The 0% position indicates a closed

valve.

• The 100% position indicates an open valve.

The resistance value is measured between terminals 16 and 17.

How to calibrate potentiometer

You can calibrate the zero of the potentiometer with the 0% position

screw. Use a flat blade screwdriver to turn this screw.

1. Drive the actuator to the CLOSED position.

2. Hold the pinion located just under the plate marked with the

0% position while turning the potentiometer screw.

3. Adjust the potentiometer so that the resistance value exceeds

0 Ohm and regularly increases, then turn backwards to reach

the closest value to 0 Ohm.

4. Drive the actuator to the OPEN position and write down the

resistance value corresponding to the 100% position.

5. Come back to the CLOSED position and check that the

resistance shows a repeatable near zero value for the 0%

position.

Signal inversion

To change the signal variation direction, invert the potentiometer

wires on the terminal block (e.g. for a connection on 16/17/18,

invert 16 and 18).

Loading...

Loading...