21

EXPRESS DUAL • ED3000

© Bernhard and Company Limited

8. Maintenance

8.1

Grinding Wheel Replacement

NOTE Grinding wheels should always be tted by competent, trained personnel.

8.1.1 The grinding wheel (stone) is held on the carrier by a nut which should be loosened, using

the “C” Spanner provided, before the assembly is removed from the mainshaft.

8.1.2 Slide the grinding wheel to the left hand side of the machine (viewed from the operator

position).

8.1.3 Release the 2 allen screws in the bearing ange ring on the left hand end of the main

shaft.

8.1.4 Raise the mainshaft to its maximum height,

maintaining the shaft as horizontal as possible

until the right hand side comes up against the stop in the feed column and the left hand

side is at its maximum height. At this point the fork will drop away from the grinding wheel

assembly.

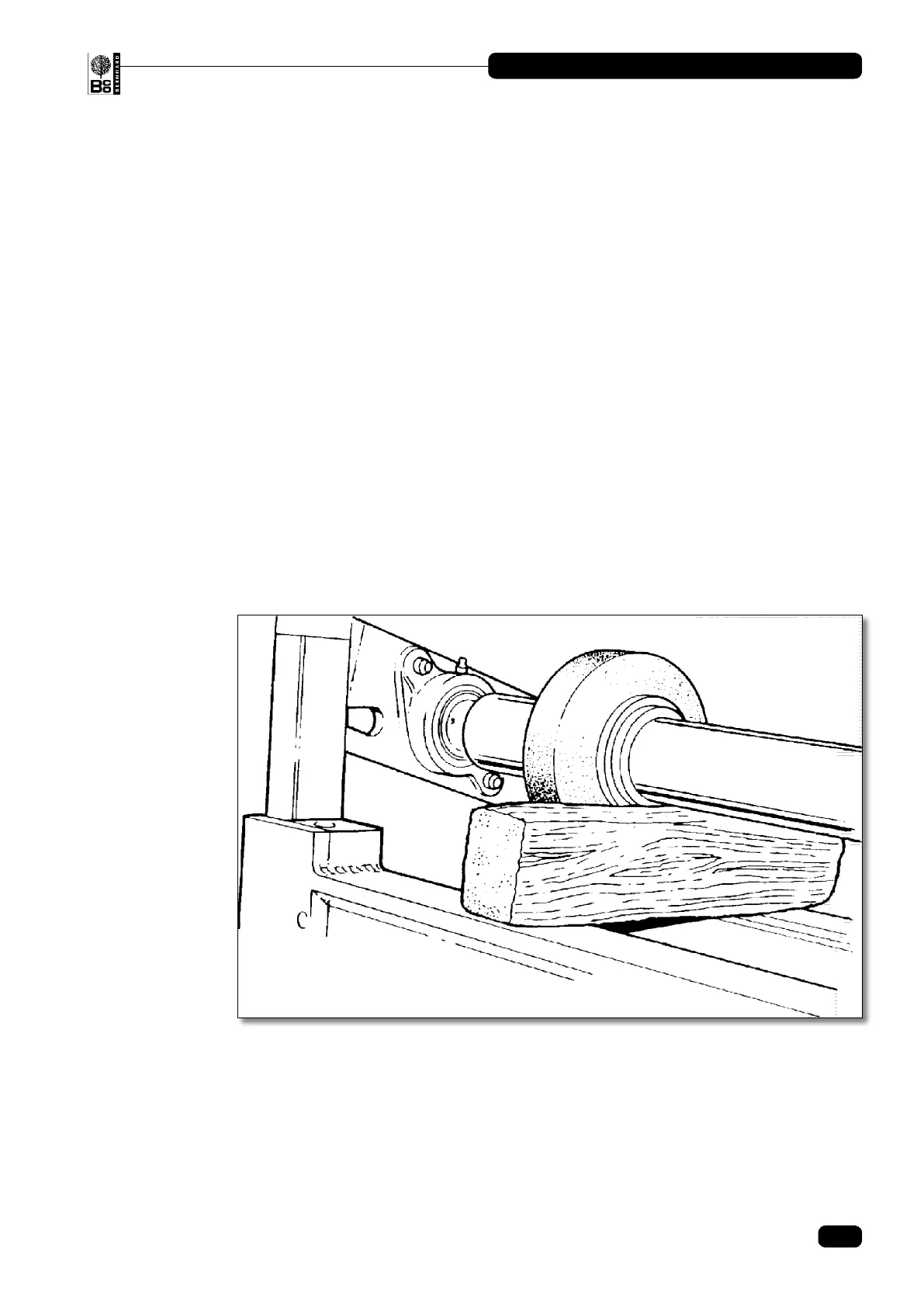

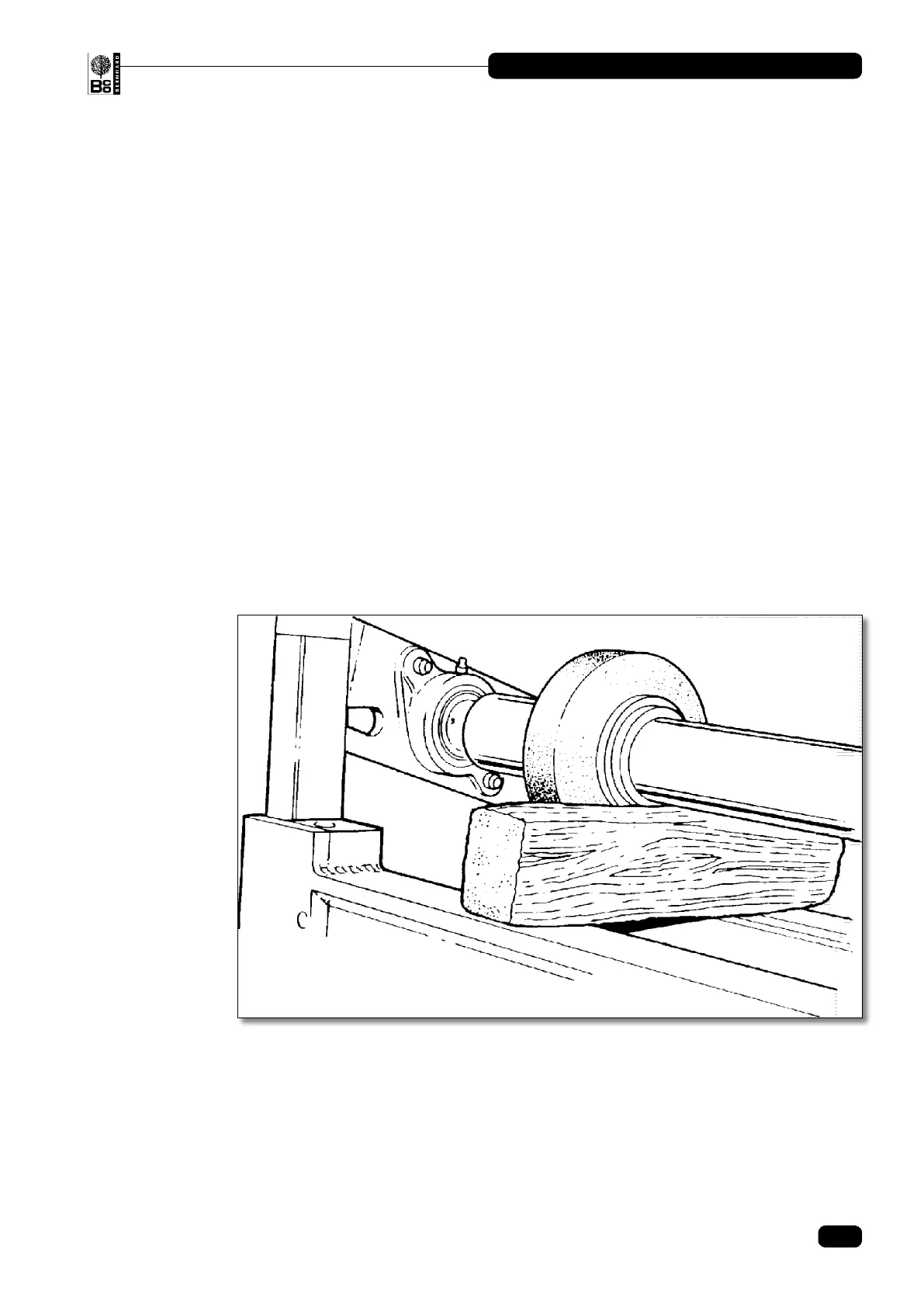

8.1.5 Place a wooden block under the mainshaft to the right hand side of the grinding wheel

assembly, bridging the front bed and front channel to take the weight of the mainshaft

when the side arm is removed (see Fig. 8.1.5).

Fig: 8.1.5

Loading...

Loading...