Bertec Corporation Instrumented Treadmill Manual 11

Site Preparation

In case of a oor installation, at least a 60 cm (2 ft) area on all sides of the treadmill should be clear and unobstructed for a proper

installation.

In case of a pit installation, pit length and width should be at least 120 cm (4 ft) larger [60 cm (2 ft) on each side] than the

dimensions of the treadmill (L x W). In case of suspended ooring these minimum dimensions apply to the units of the raised

oor that needs to be removable (to decide on the exact locations of the support columns for suspended ooring consult Bertec

Corporation for detailed dimensional drawings). For a ush tread surface, 6 mm (¼”) should be added to the height of the

treadmill (parameter H in Figures 7 and 8). As indicated previously, the oor (bottom of the pit) should be at within ±⅛". The

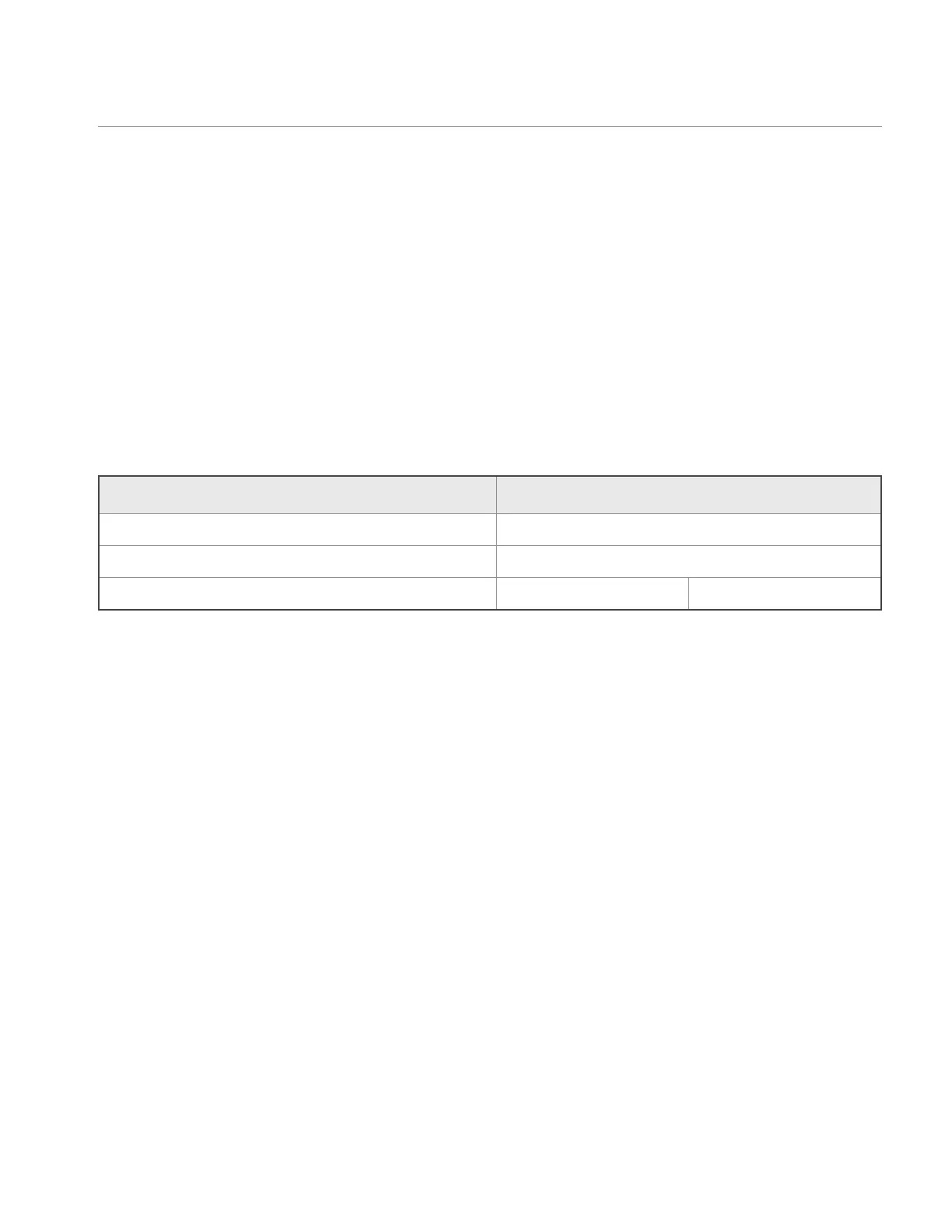

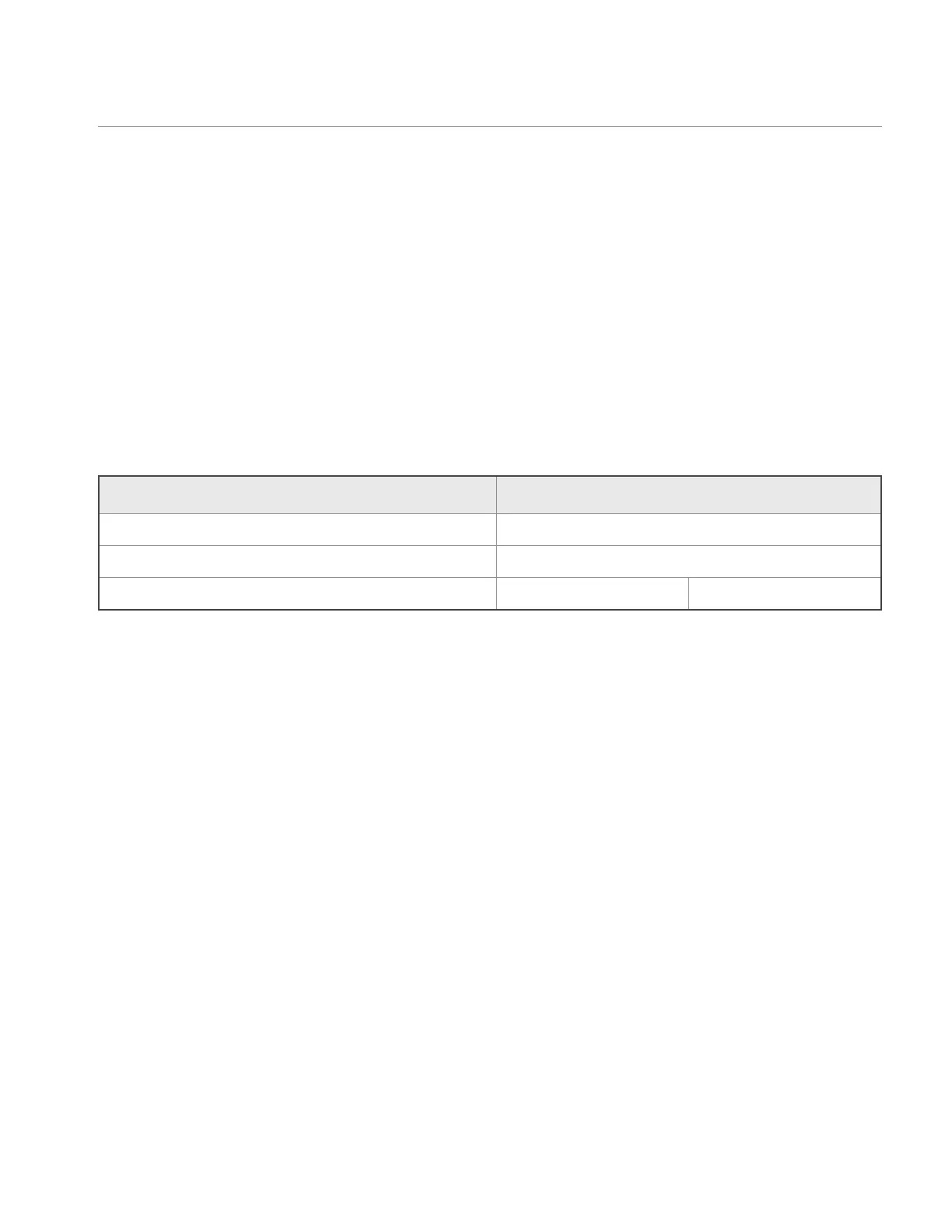

following table summarizes the required dimensions for the treadmill pit:

FIGURE 4: Required pit dimensions for instrumented treadmill

Parameter Dimensions

Minimum pit length, cm (in) L + 120 (L + 48)

Minimum pit width, cm (in) W + 120 (W + 48)

Pit depth, mm (in) H + 6 (H + 0.25) Tolerance: ±3 mm (±⅛")

Note that for systems with the optional incline module, extra space is needed between the treads and adjacent false ooring to

allow the extra rotational motion of the incline unit.

Incorporating a wire conduit into the pit construction is recommended for safety reasons to avoid tripping over the cables. The

recommended diameter is 10 cm (4”) for straight conduits and 13 cm (5”) for conduits with bends and turns. Since the standard

length of the cables running between the treadmill and the electronics control unit is 9 m, the cable conduit lengths should be

sized accordingly allowing for any amount of extra slack cable needed. A guide wire should be available in the conduit to run the

cables. Alternatively, the cables can be run under the false ooring. In case of oor installations, over-the-oor cable covers can

be used as a safety precaution.

The pit should be cleaned thoroughly after construction and should be free of any debris and dust. Cleaning with a vacuum

cleaner is strongly recommended, as dust particles will prevent the mounting plate epoxy to attach to the oor properly.

Installation

Loading...

Loading...