11

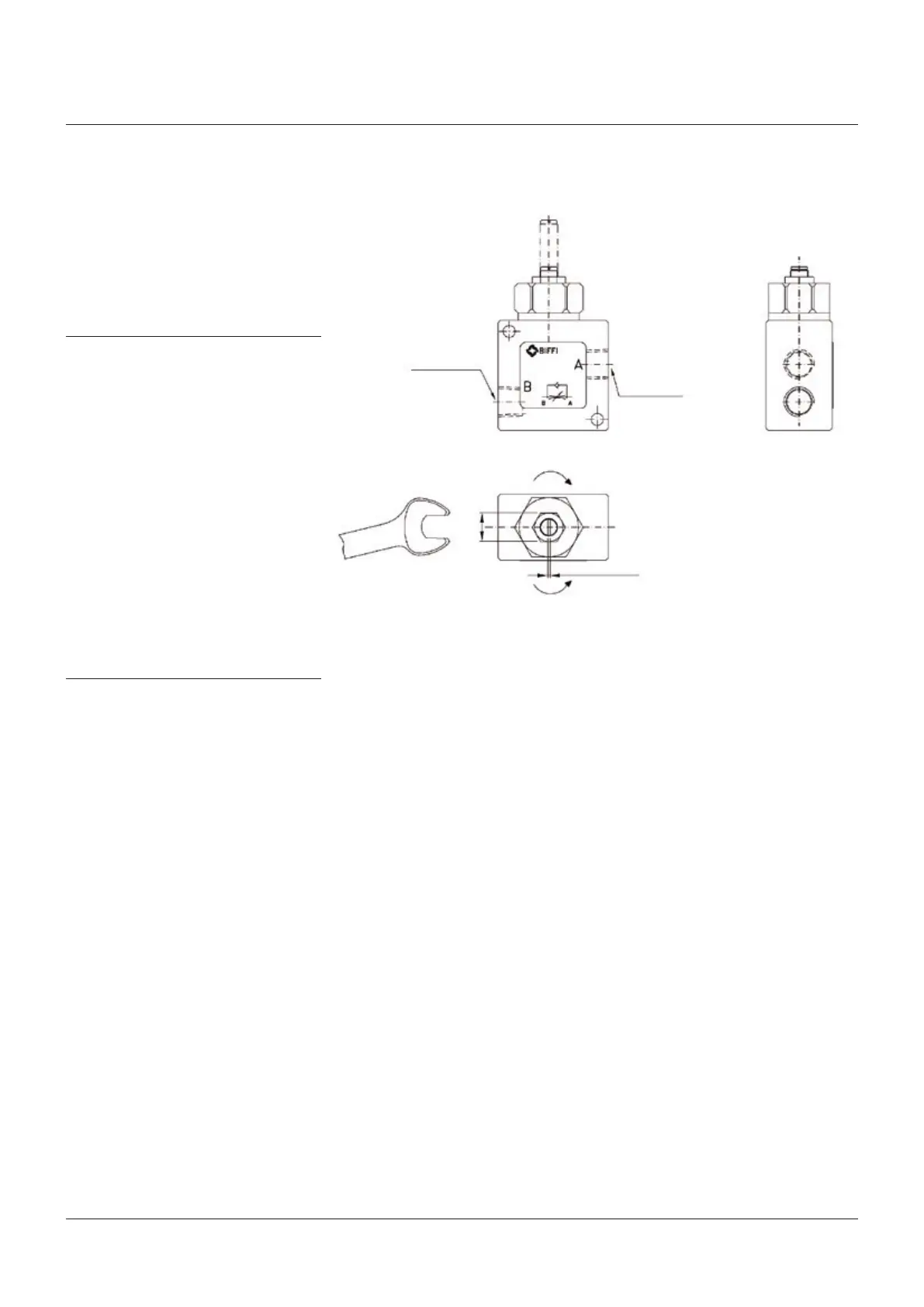

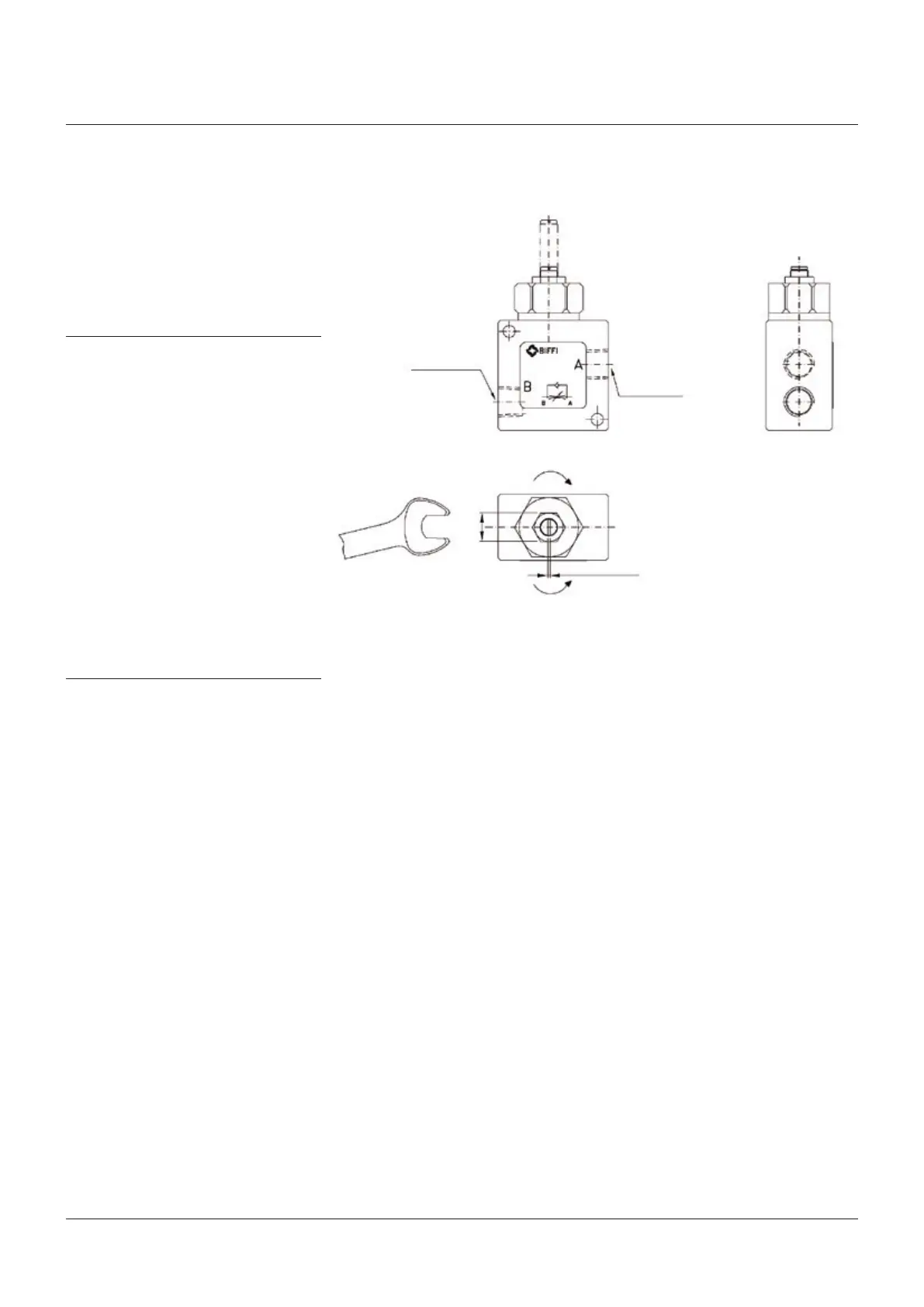

3.5 Calibration of the operating time

(optional- if foreseen)

The calibration of the operating time is made

according to customer requirements and to

technical data sheet included in technical

documentation. If necessary it’s possible to

modify or reset the operating time through

the flow regulator valve placed on inlet of

pneumatic supply (figure 19).

Pneumatic connection

Pneumatic connection

(close) screw for decrease speed

(open) unscrew for increase speed of operation

Screwdriver

Wrench

FIGURE19

Example of operating time adjustment by flowregulator valve (please refer to specific operating

diagram)

4 OPERATIONAL TESTS AND INSPECTIONS

IMPORTANT

To ensure the guaranteed SIL Level, according

to IEC 61508, the functionality of actuator must

be checked with regular intervals of time, as

described following.

For safety related applications, the following

test operation has to be performed:

1. Full stroke of actuator once a year.

2. Partial stroking test at least every six

months (if applicable, please refer to

operating diagram and operate accordingly).

3. Visual inspection-checks , according to

section 5.1, but with a frequency of once

a year.

For standard applications please refer to

section 5.1.

5 MAINTENANCE

IMPORTANT

Before executing any maintenance operation, it

is necessary to close the pneumatic supply line

and discharge pressure from the cylinder of the

actuator and from the control unit (if foreseen).

WARNING

Installation, commissioning and maintenance

and repair works should be carried out by

qualified staff.

5.1 Periodic maintenance

RPS actuators are designed to operate long-

term in heavy-duty operating conditions,

without maintenance needs.

IMPORTANT

Periodicity and regularity of inspections is

particularly influenced by specific environmental

and working conditions.

They can be initially determined experimentally

and then be improved according to actual

maintenance conditions and needs.

Anyway every 2 years of operation the following

is recommended:

• Check that the actuator operates the valve

correctly and with the required operating

times. If the actuator operation is very

infrequent, carry out a few opening and

closing operations with all the existing

controls (remote control, local control,

emergency controls, etc.), if this is allowed by

the conditions of the plant.

• Check all the paint-coat of the actuator.

If some areas are damaged, repair the

paint-coat according to the applicable

specification.

• Check there are no pneumatic leakages If

necessary tighten the nuts of the pipe-fittings.

• Check the integrity of worn out parts (gaskets,

pads etc.).

• If there is an air filter on the actuator, bleed

the condense water accumulated in the cup

by opening the drain cock. Disassemble the

cup periodically and wash it with soap and

water; disassemble the filter: if this is made

up of a sintered cartridge, wash it with nitrate

solvent and blow through with air. If the filter

is made of cellulose, it must be replaced

when clogged.

RPS SPRING RETURN PNEUMATIC ACTUATOR

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Loading...

Loading...