4

3A

3B

RPS SPRING RETURN PNEUMATIC ACTUATOR

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

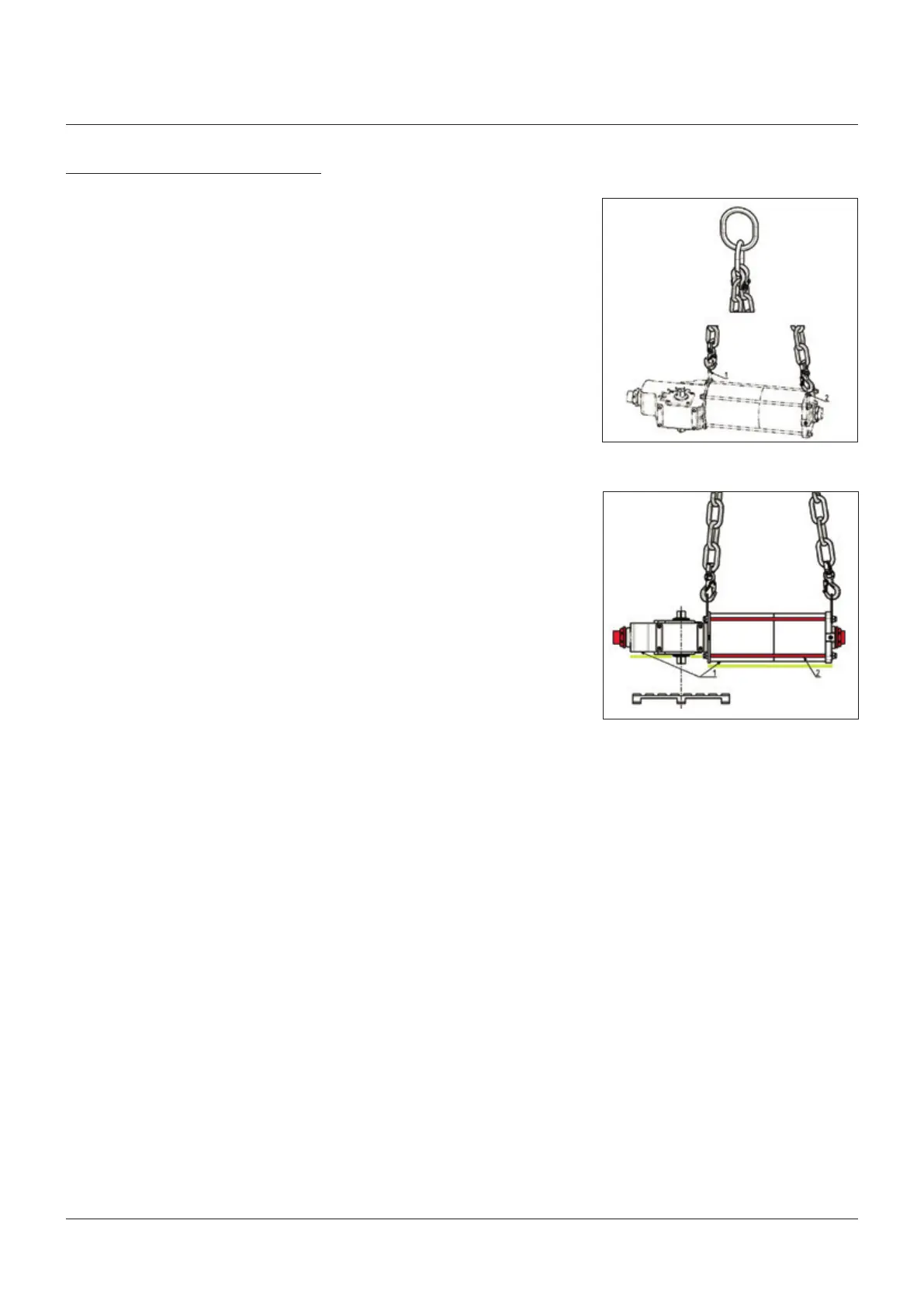

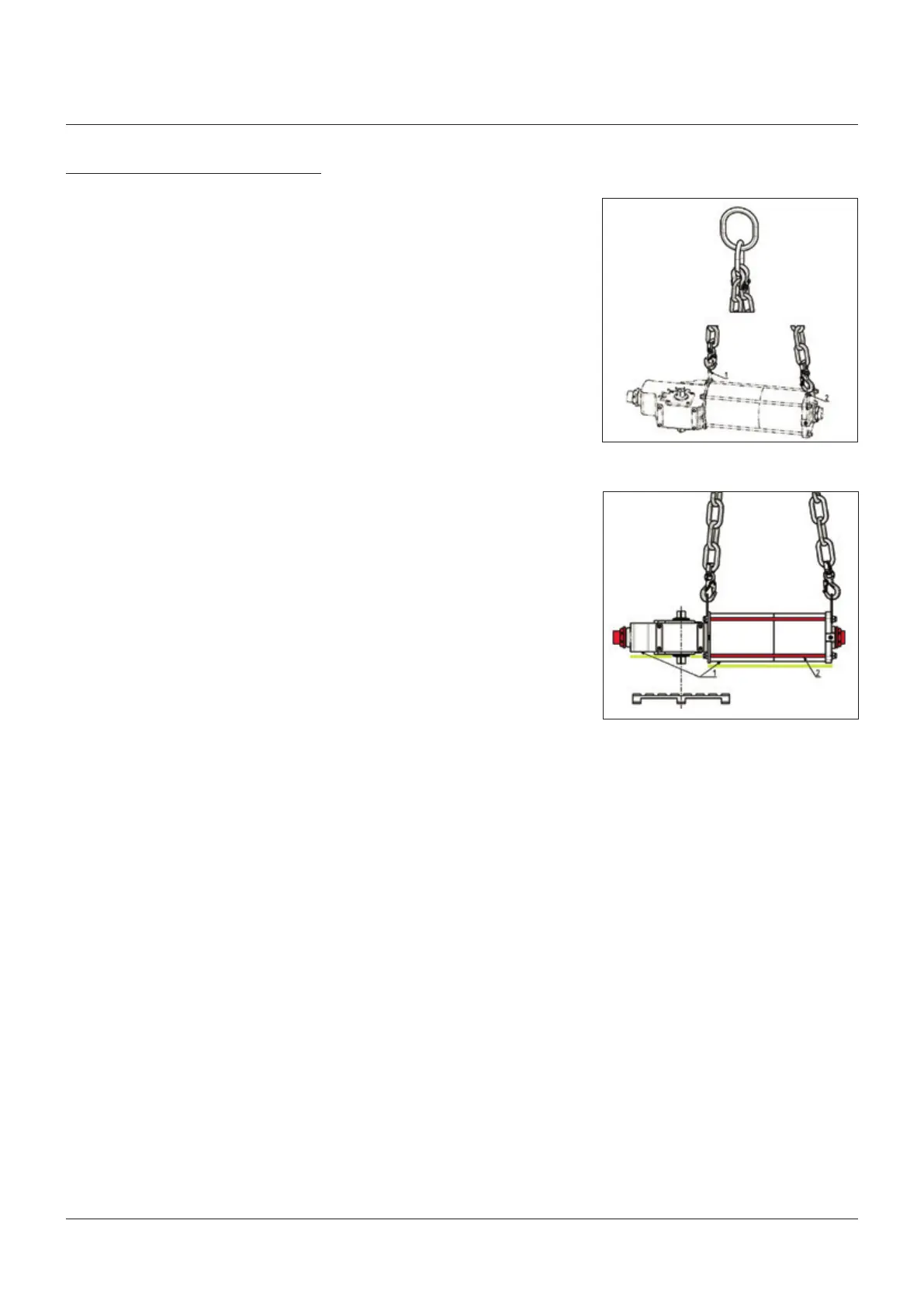

2.2 Actuator handling

A. Valve stem with vertical axis

IMPORTANT

The lifting and handling should be made by

qualified staff and in compliance with the laws and

provisions in force.

WARNING

The fastening points are appropriate for the lifting

of the actuator alone and not for the valve and

actuator assembly.

Avoid that during the handling, the actuator

passes above the staff.

The actuator should be handled with appropriate

lifting means. The weight of the actuator is

reported on the delivery bill.

For a correct lifting procedure, please refer to

figure 3A, 3B.

A. Valve stem with horizontal axis

The actuator can also be lifted to assemble

directly onto the valve with stem with horizontal

axis. To make this operation easier, Biffi

suggest to move the lifting eyelet from its

standard position, and place it in the suggested

position, see figure 4.

2 INSTALLATION

2.1 Checks upon actuator receipt

• Check that the model, the serial number of

the actuator and the technical data reported

on the identification plate correspond with

those of order confirmation (section 1.2).

• Check that the actuator is equipped with the

fittings as provided for by order confirmation.

• Check that the actuator was not damaged

during transportation: if necessary renovate

the painting according to the specification

reported on the order confirmation.

• If the actuator is received already assembled

with the valve, its settings have already been

made at the factory.

If the actuator is delivered separately

from the valve, it is necessary to check,

and, if required, to adjust, the settings of

the mechanical stops (section 3.4) and of

microswitches (if any) (section 3.5).

FIGURE 3A, 3B

Lifting points for RPS actuators

1 = Points of support

2 = Do not lay the actuator on tie-rods

WARNING

Do not lay the actuator on accessories (manual

hand pump, manual jackscrew, pneumatic control

system etc.)

1, 2 = Lifting eyelets

Loading...

Loading...