9

1

1

2

3

2

2

P

3

4

5

1

P

RPS SPRING RETURN PNEUMATIC ACTUATOR

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

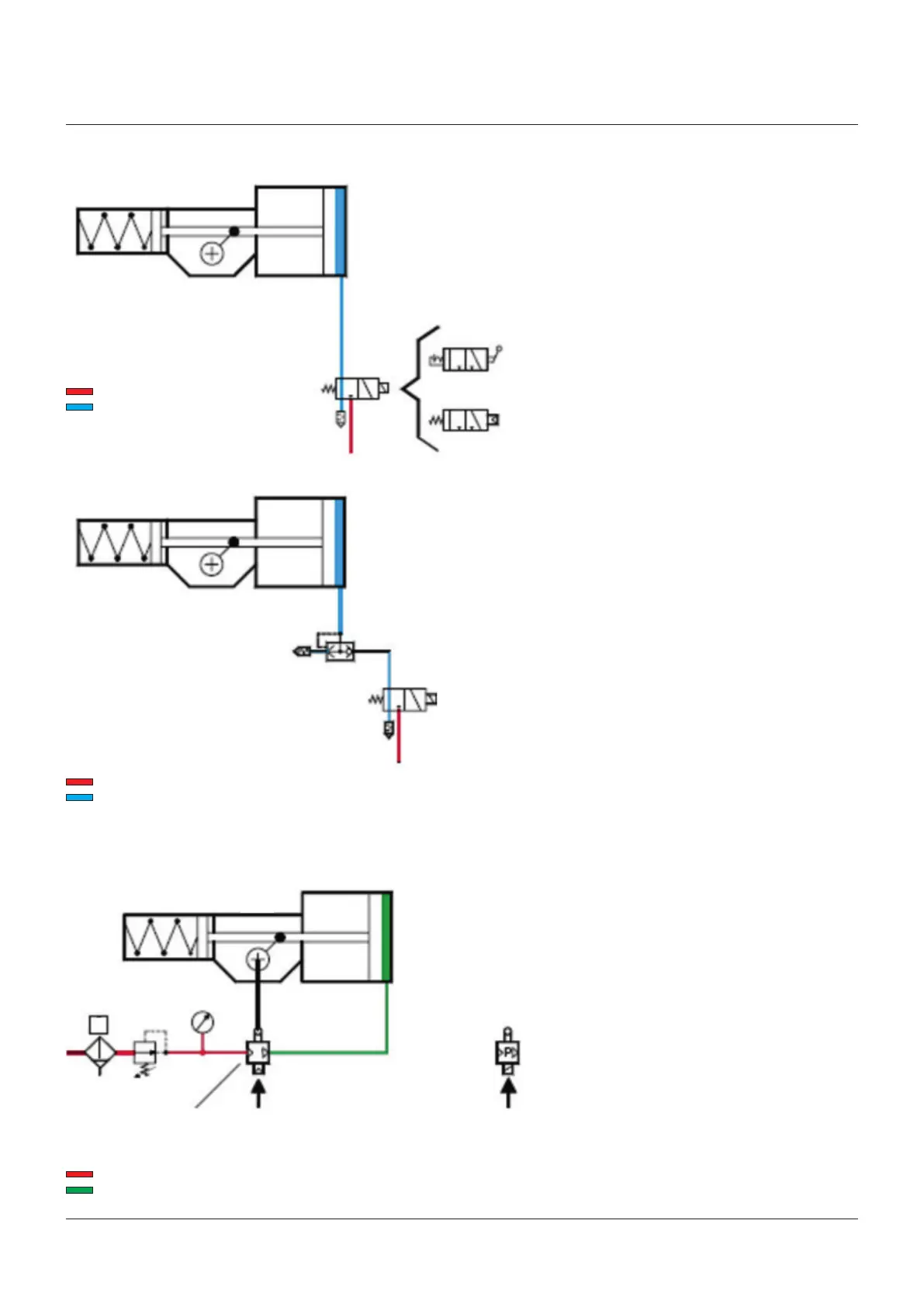

On-Off service: three way control valve

The diagram shows the simplest On-Off

control. The control valve (2) has two positions.

In one position the gas supply pressure is

connected to the cylinder chamber, and the

actuator performs the “pneumatic” operation.

In the other position the cylinder is connected

to the exhaust and the actuator moves under

the operation of the spring.

The control valve can have many types of

actuating devices (solenoid, manual control,

pneumatic pilot, spring, etc.).

The spring return control valves allow

“failsafe” operation.

On-Off service: quick spring operation

When fast action is required under spring

operation, a quick exhaust valve (3) is installed

in the cylinder directly port to exhaust the gas

from the cylinder directly to the atmosphere.

When the control valve (2) opens to the

atmosphere a differential pressure is created

across the quick exhaust valve (3) causing it

to open. The resultant high flow capacity from

cylinder to atmosphere allows quick spring

operation of the actuator.

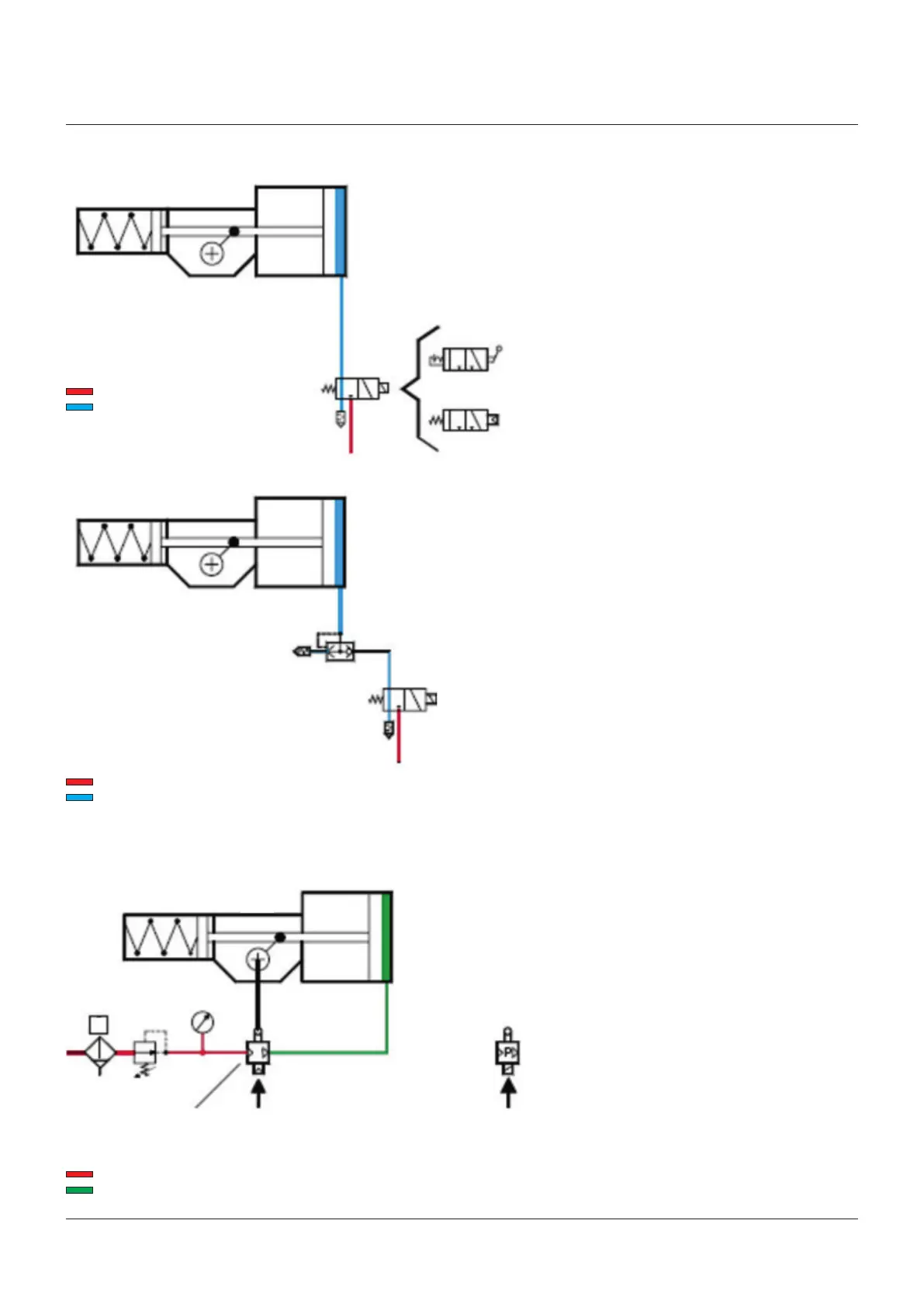

Modulating service

When modulating control is required as a

function of a pneumatic or electric control

signal, a positioner (5) is used, which controls

the supply to the actuator cylinder to keep the

valve in the required angular position.

The positioner has a mechanical linkage to the

actuator, for a feedback of the valve position.

Pressurized air

Atmospheric pressure air

Manual

control

Pneumatic

pilot control

Pneumatic

positioner

Pneumatic

control signal

Electric

controlsignal

Electropneumatic

positioner

Pressurized air

Atmospheric pressure air

Pressurized air (supply)

Reduced pressure air

Solenoid

control

FIGURE 8A

FIGURE 8B

FIGURE 8C

Loading...

Loading...