REV A 4-6 122832

ing information can be used to install and test the pump by

simulating a wheel motor load.

Bi-Directional Flow Test Kit Installation

Disconnect the system hoses at the wheel motor, or sys-

tem hoses from the pump and connect the Bi-Directional

Flow Test Kit. (Special care should be taken to prevent con-

tamination debris from entering pump or wheel motor sys-

tem ports).

NOTE: Using the Bi-Directional Flow Test Kit, determina-

tion of directional flow is not necessary. The flow meter may

be connected in either direction into the forward and reverse

high pressure system lines.

NOTE: The following adapter fittings will be required when

connecting the Bi-Directional Test Kit (Excel P/N 783886 or

Hydro-Gear P/N 70661):

PG/PL Series Pumps require two 771311 adapter fittings

PJ Series Pumps require two 771311 adapter fittings

CAUTION: Ensure all fittings and hoses are attached

securely. This test is being completed on the vehicle’s high

pressure system lines. Failure to perform this properly could

result in bodily injury.

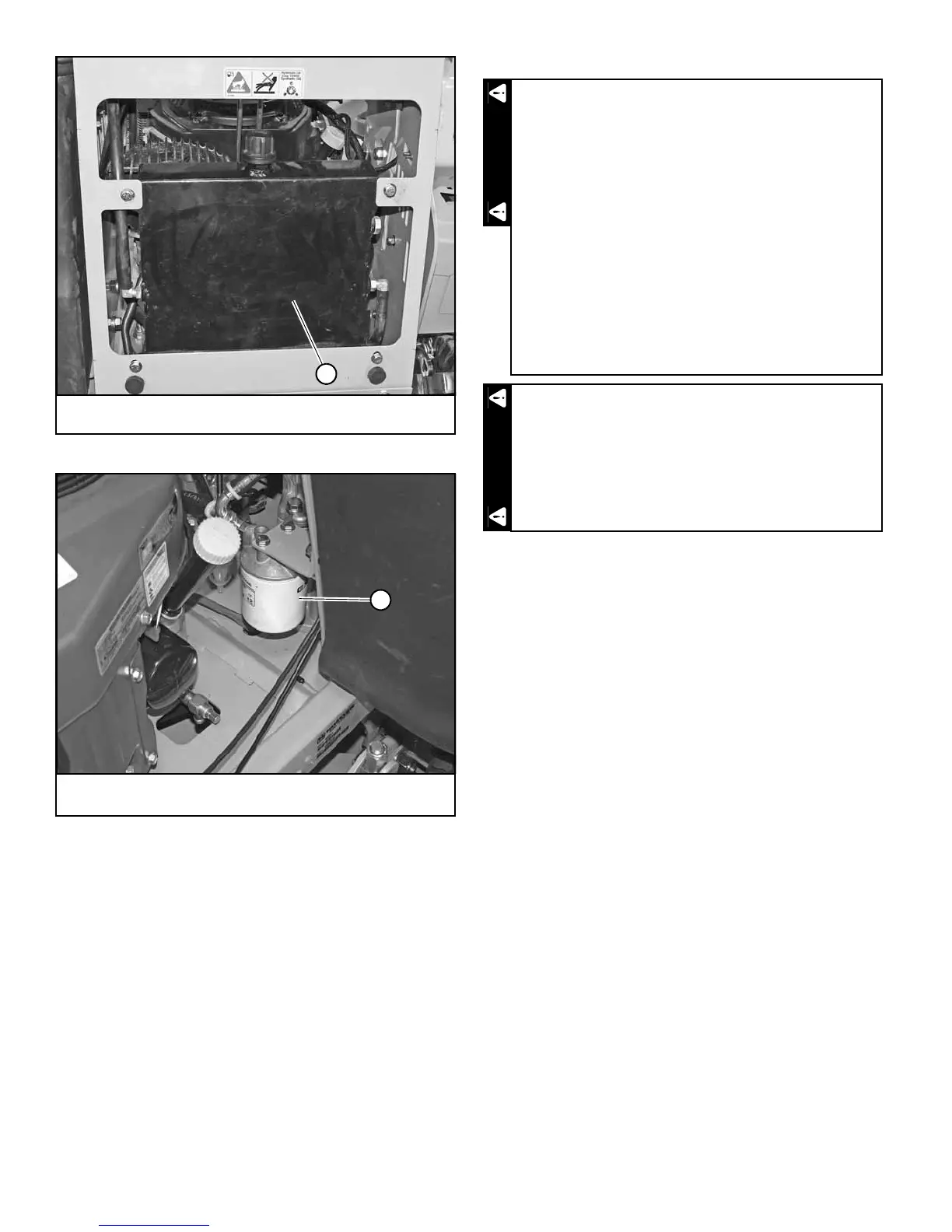

A. Hydraulic reservoir

Figure 4-10

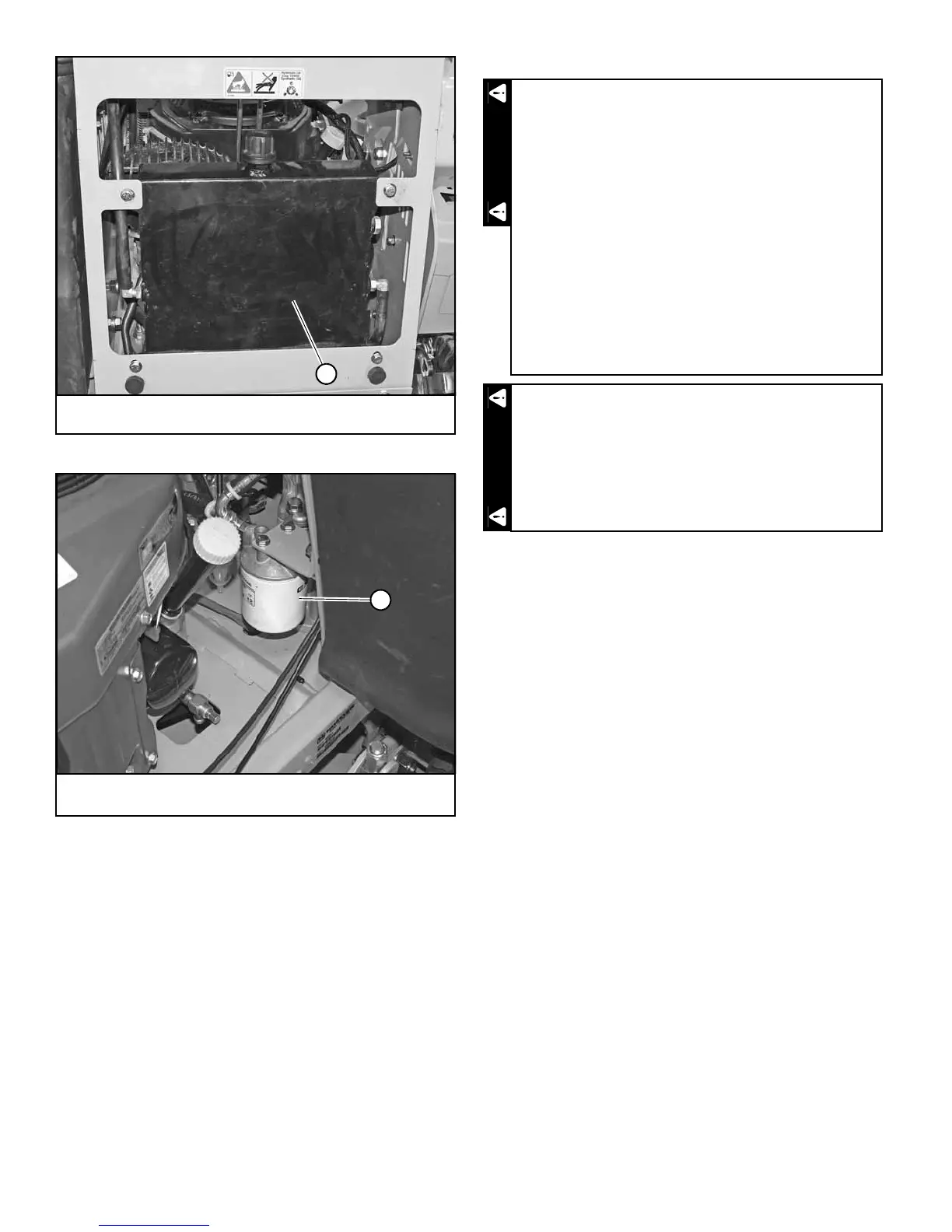

A. Hydraulic filter

Figure 4-11

Potential for serious injury! Never work under the

machine or attachment unless it is safely sup-

ported with jack stands. To prevent possible injury

to the servicing technician and/or bystanders,

ensure the vehicle is properly secured.

• Make certain machine is secure when it is

raised and placed on the jack stands.

• Use only certified jack stands. Use only

appropriate jack stands, with a minimum

weight rating of 2000 pounds (907 kg) to

block the unit up.

• Use in pairs only.

• Follow the instructions supplied with the

jack stands.

Do not attempt any adjustments with the engine run-

ning. Use extreme caution while working in or around

all vehicle linkage! High temperatures can be gener-

ated. Follow all safety procedures outlined in the

mower’s operator’s manual!

Loading...

Loading...