122832 5-3 REV A

4. Check all fittings and clamps periodically for tightness

and inspect hoses for holes or cracks.

5. Periodically check the intake hose for signs of

ingested dust. Locate and repair the source of

ingested dirt.

6. Never operate the machine without an air filter

installed.

Overservicing

Overservicing occurs when an air filter element is removed

for cleaning or replacement before it is necessary. Each time

the filter is removed a small amount of dirt and dust could

fall in the intake system. This accumulated dirt can cause a

dusted engine. It only takes a few grams of ingested dirt over

the normal service life of an engine to cause a dusted engine.

Do not clean the element, but replace with a new element

only. Cleaning used air filter elements, through improper

cleaning procedures, can get dust on the inside of the filter

causing dirt ingestion and engine failure.

It is important to note that whenever an air filter element is

cleaned by any method, the person or company performing

the cleaning assumes responsibility for the integrity of the

filter from then on. The warranty for air filters expires upon

cleaning or servicing in any manner because the condition of

the filter after servicing is completely out of the filter manufac-

turer’s control. Therefore, on a dust ingested engine failure,

there will be no warranty consideration if the air filter element

has been cleaned or serviced in any manner.

A partially dirty air filter element works better than a new

element. Therefore, a dirty filter element is not bad for the

engine unless it is excessively restricting the air flow and

engine performance is affected. The reason is simple. The

media in the filter must be porous to allow air to pass

through it. When dirty air passes through the filter, the dirt

plugs some of the holes in the media and actually acts as

part of the filter media. When the next round of dirt enters,

the first dirt helps filter out even smaller particles making the

filter more efficient at stopping dirt from entering the engine.

This is referred to as barrier filtration.

Of course, at some point the filter media becomes too

clogged to allow air to pass.

The mowing conditions will determine the frequency of air

filter element changing.

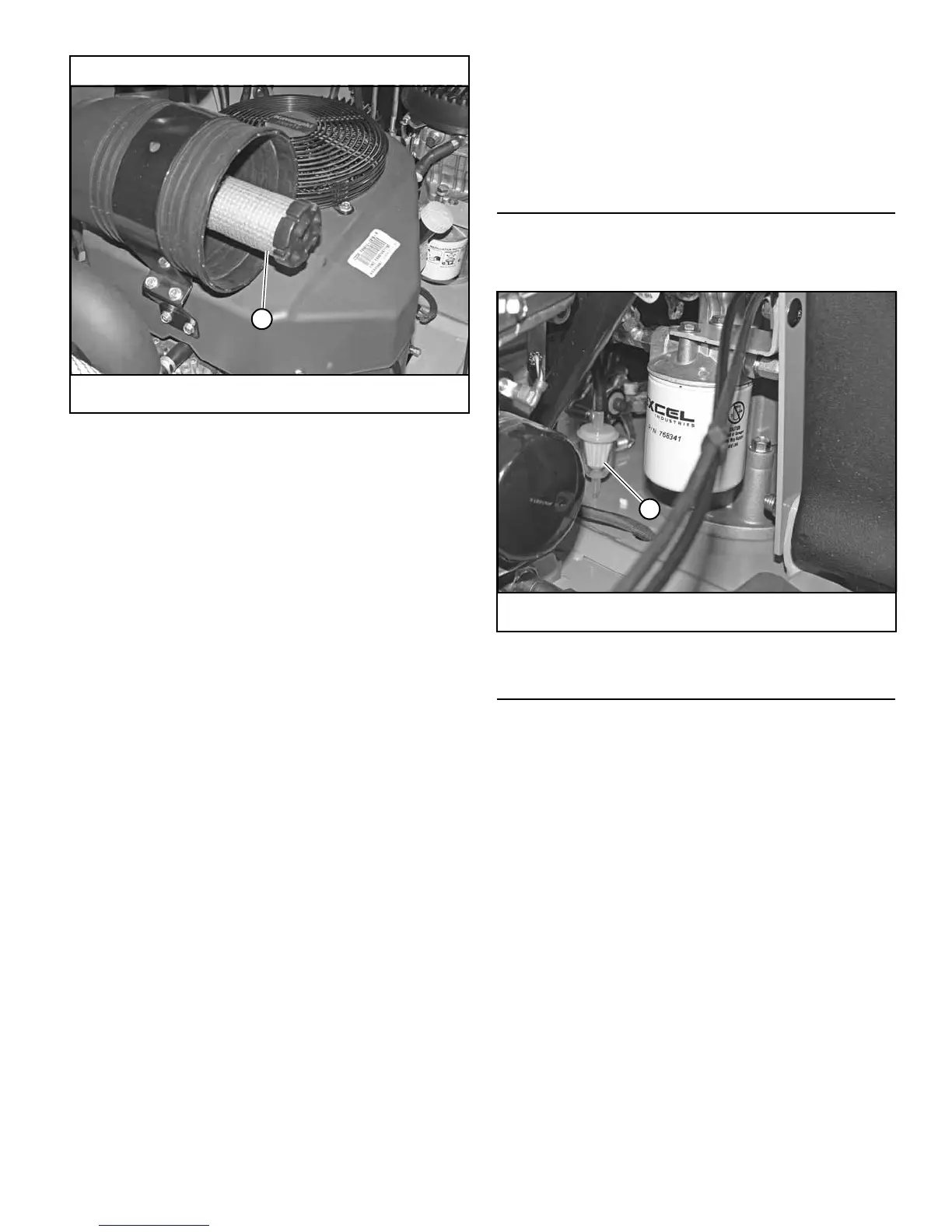

Fuel Evaporation System Filter

These mowers have a fuel evaporation system filter. This

filter must be checked and replaced every 500 hours or annu-

ally whichever comes first. Figure 5-8

Fuel & Evaporative System Line Routings

These mowers have a fuel evaporative system installed.

There are two different types of rubber hoses that are con-

nected to the fuel tank. One is the fuel hose that is part of the

fuel system. The other is the vapor line that is part of the fuel

evaporative system.

The fuel hose is connected to the fuel tank as shown. It

connects the fuel tank to the engine’s fuel pump. Figure 5-9,

Figure 5-10 & Figure 5-11

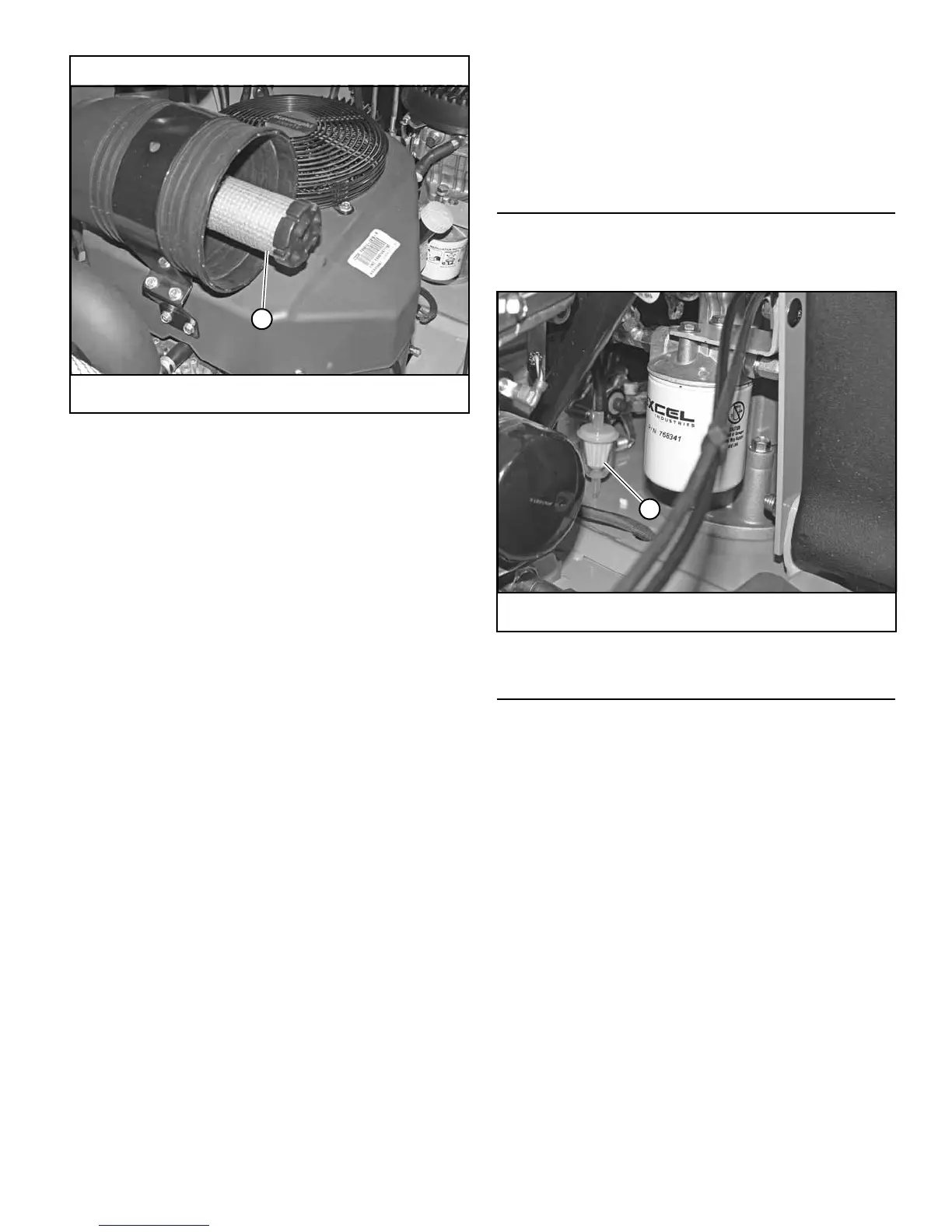

Kawasaki FX691V/FX730V engine

A. Safety filter

Figure 5-7

A. Fuel evaporation system filter

Figure 5-8

Loading...

Loading...