8 Extruder Operations BigRep STUDIO

80

8. Extruder Operations

Please read the following instructions carefully before starting.

8.1. Changing Filament

Safety Instructions

Only use filament that is suitable for your printer. For good results we recommend

tested filaments, which can be ordered via [www.bigrep.com].

Some filaments may develop harmful vapors during printing. Please also refer to

the specifications by the individual manufacturers.

Procedures

1a. Filament Change Before the Printing Process

The extruder must be preheated to the required print temperature before

the filament change.

& Chap. 7 Operation and Control

1b. Filament Change During the Printing Process

Pause the print and move the extruders to a position away from the print.

Note: Only move on the X-Y axis! Continue with step 3.

1c. Filament Change in Case of Out Of Filament Notification

When Out-of-filament-sensor is triggered, the print will automatically pause.

Move the extruders to a position away from the print.

Note: Only move on the X-Y axis!

2. Manually move the extruder into a position that allows for easy filament re-

placement.

& Chap. 6.1 Control Menu

3. Go to the Control Menu and extrude 50 mm

4. Go to the Control Menu and click Unload.

Automatically the extruder will:

– Heat to 220° C

– Extrude a small amount of material

– Retract the filament

If you would like to unload the filament from T0

and T1, wait for the first unloading procedure to

be finished before starting the second one.

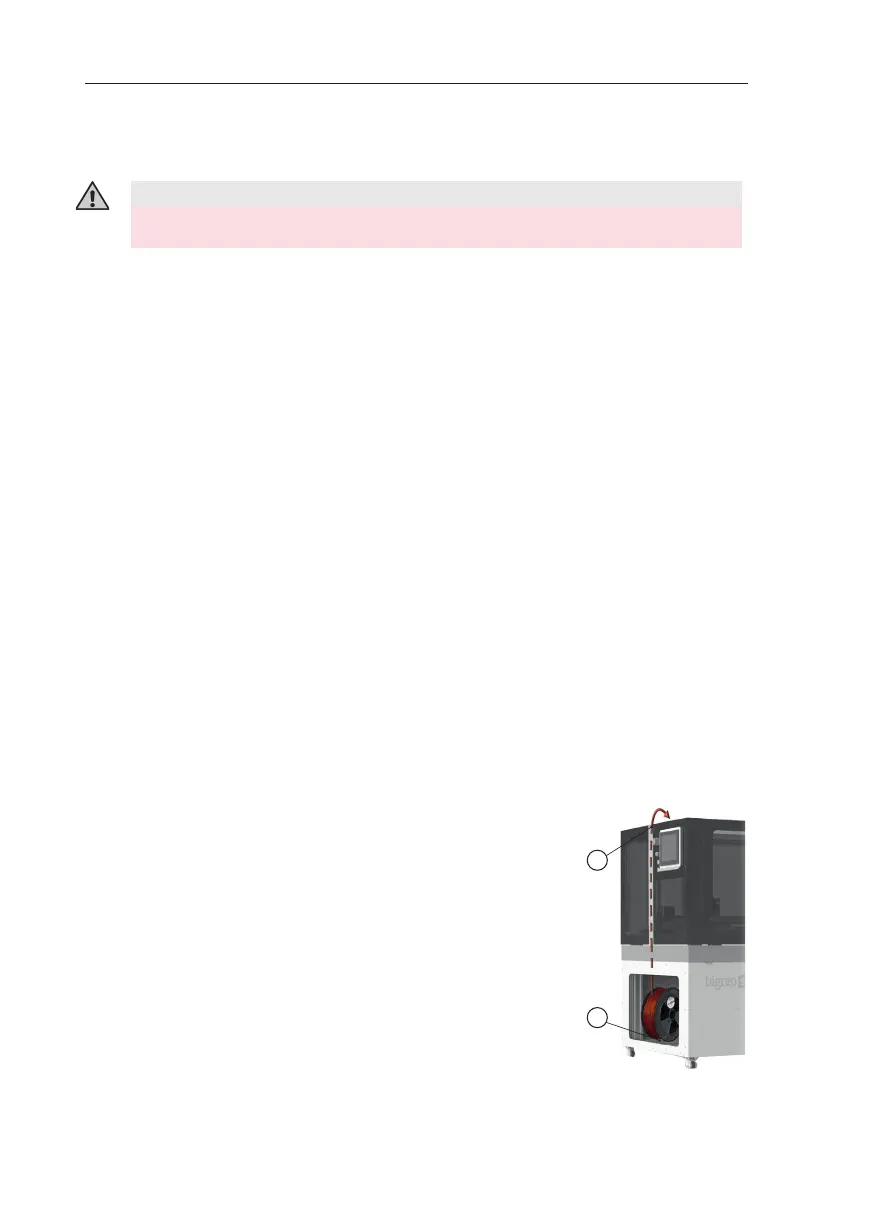

5. Pull out the old filament spool from the fil-

ament spool holder. If the spool still contains

A

F

Fig. 8-1: Loading filament

Never reach into the printer while the machine is running.

WARNING – Danger of Crushing

Loading...

Loading...