FDL (E2.1) 05/2016 page 15/75

2.2 Control panel

(6) (5) (4) (3)

(2) (2a) (2b) (1)

Figure 4: Control panel of FDL 115 standard chamber

(1) Main power switch ON/OFF

(2) Temperature safety device class 2

(2a) Red pilot lamp for temperature safety device class 2

(2b) RESET key for temperature safety device

(3) Red indicator light “AIR”: Heating turned off during prepurge or due to insufficient exhaust air

stream (loss of technical ventilation)

(4) Pushbutton “START”: starts the fan and the prepurge procedure

(5) Temperature program controller RD3

(6) Solvent curve: Highest permissible amount of solvent G

total [g] as a function of the drying tempera-

ture

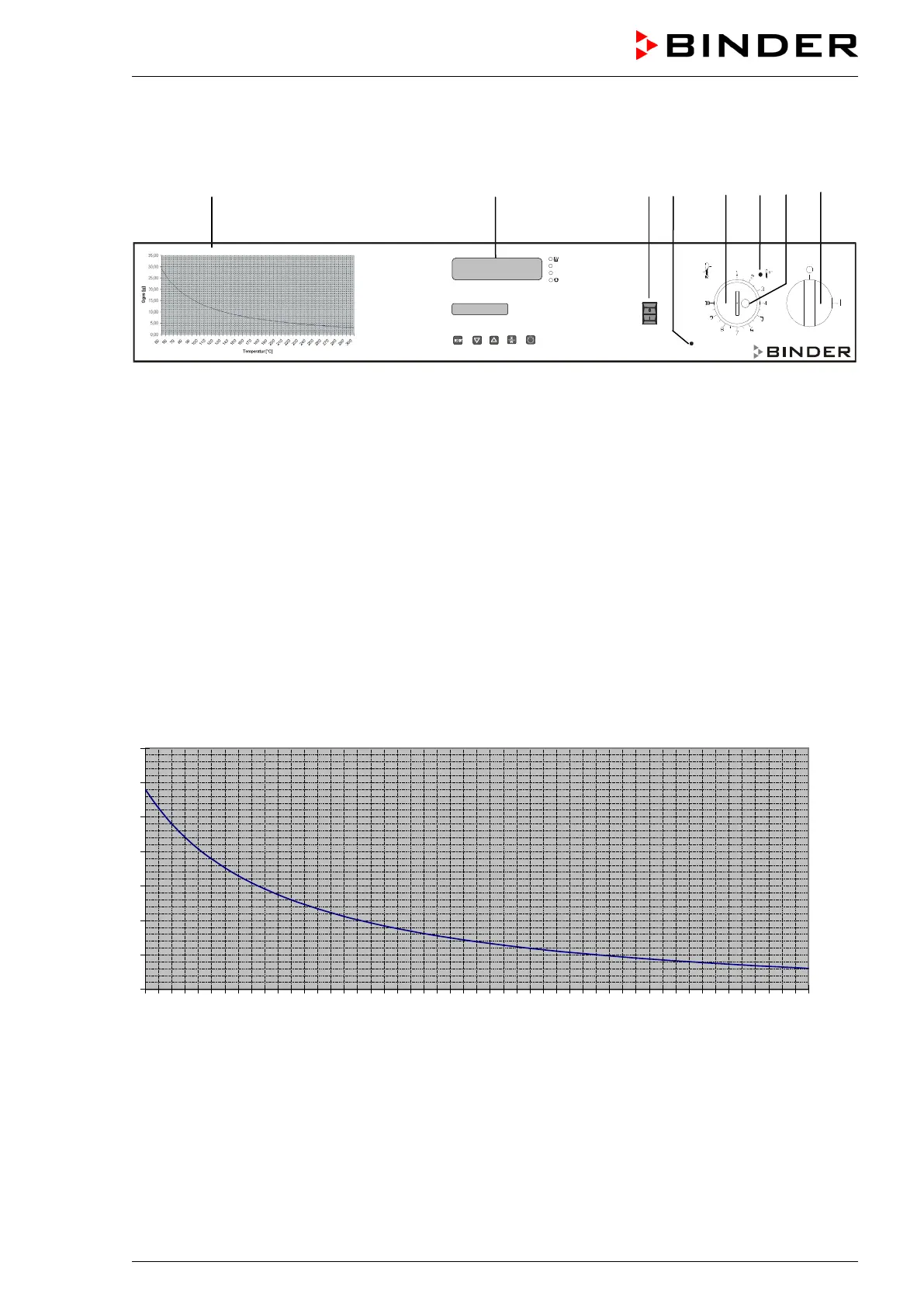

2.3 Solvent curve FDL 115

0,00

5,00

10,00

15,00

20,00

25,00

30,00

35,00

Figure 5: Solvent curve FDL 115

The diagram shows the highest permissible solvent quantity G

total [g] in the steam room in correspond-

ence to the drying temperature. This is based on the calculation acc. to EN 1539:2015 considering the

chamber specific data, an assumed molecular weight of the solvent of 100g/Mol, and a lower explosion

limit of 40g/m

3

at 20 °C / 68 °F and at 760 Torr (1013 hPa) (assumptions for unknown solvents acc. to EN

1539:2015).

Loading...

Loading...