Issue 05/2016 Art. No. 7001-0261

Operating Manual

Translation of the Original Operating Manual

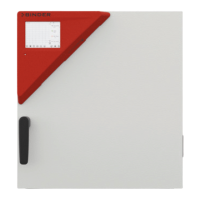

FDL 115

Safety drying ovens

for drying of limited quantities of solvents

with microprocessor program controller RD3

BINDER GmbH

Address Post office box 102

D-78502 Tuttlingen

Tel. +49 7462 2005 0

Fax +49 7462 2005 100

Internet http://www.binder-world.com

E-mail info@binder-world.com

Service Hotline +49 7462 2005 555

Service Fax +49 7462 2005 93 555

Service E-Mail service@binder-world.com

Service Hotline USA +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacific +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS +7 495 988 15 16