Issue 03/2020 Art. No. 7001-0383

Operating Manual

Translation of the original operating manual

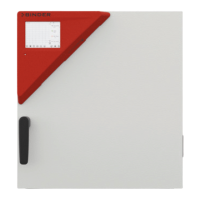

VD (E3.1)

Vacuum Drying Oven

Standard: with RD4 microprocessor program controller

Optional: with MB2 microprocessor program controller

Model Model version Art. No.

VD 23 VD023-230V 9630-0001

VD 23-UL VD023UL-120V 9630-0005

VD 56 VD056-230V 9630-0002

VD 56-UL VD056UL-120V 9630-0006

VD 115 VD115-230V 9630-0003

VD 115-UL VD115UL-120V 9630-0007

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.binder-world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: service@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacific: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16