Instruction Manual

Page 15 of 40 Issue: 2.1

N:\Engineering\Manuals\Pump Unit E2-30 & 40 R2.1.doc

Operation - Section 4.1

System Operation

Before starting: -

• Ensure all electrical and mechanical connections are correctly made.

• All required interlocks are tested and operational.

• Suitable material for pumping is available at the suction hose.

• The outlet connection is not blocked or isolated by any valves.

• Check the gearbox oil level, top up as necessary with the correct grade (see

maintenance section) and that the gearbox ventilator is fitted.

Set the pump speed to the minimum frequency 20 HZ and start the pump to remove

any air from the circuit. Inspect for any leaks.

Set the pump cycle rate to achieve the required paint volume and then adjust the

system back pressure regulator to achieve the desired system fluid pressure.

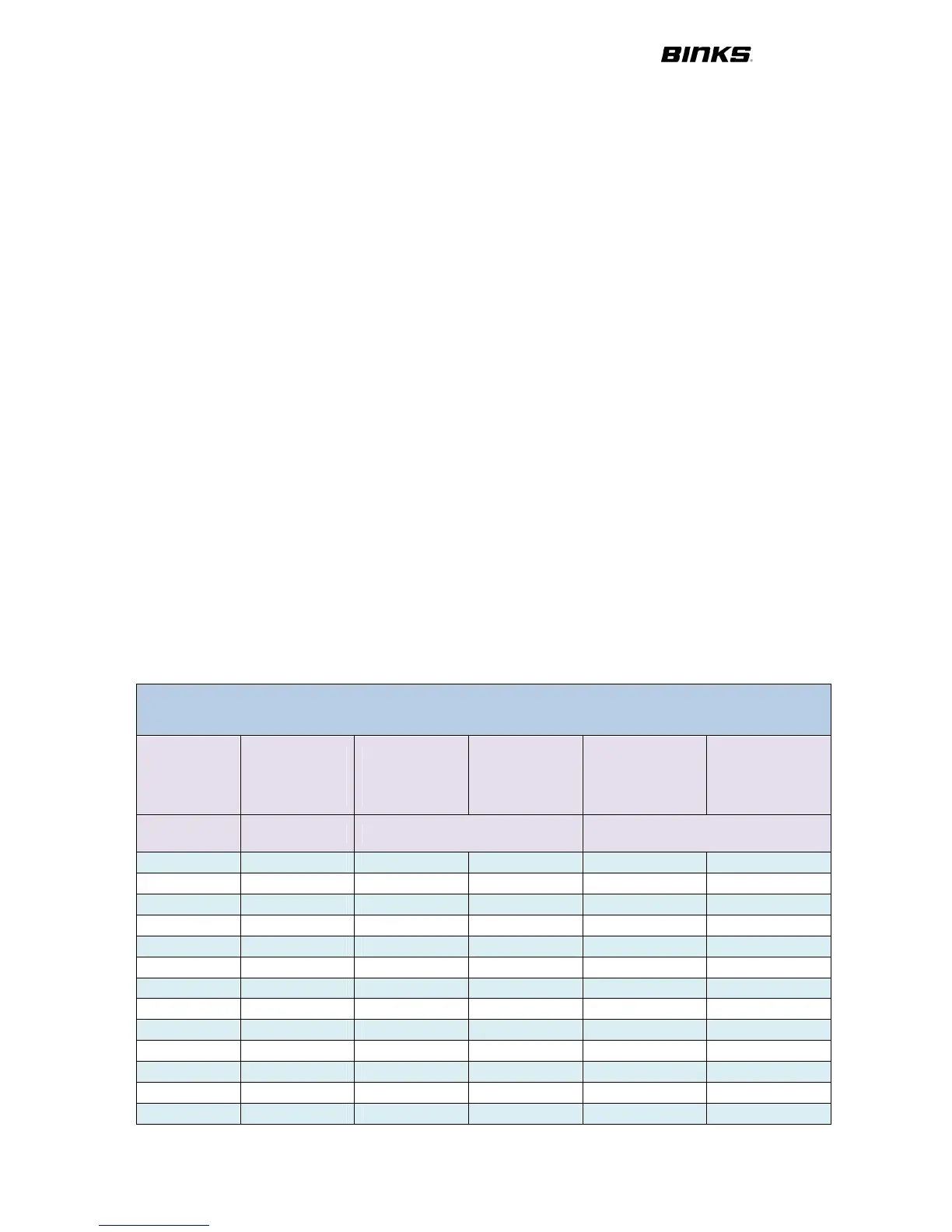

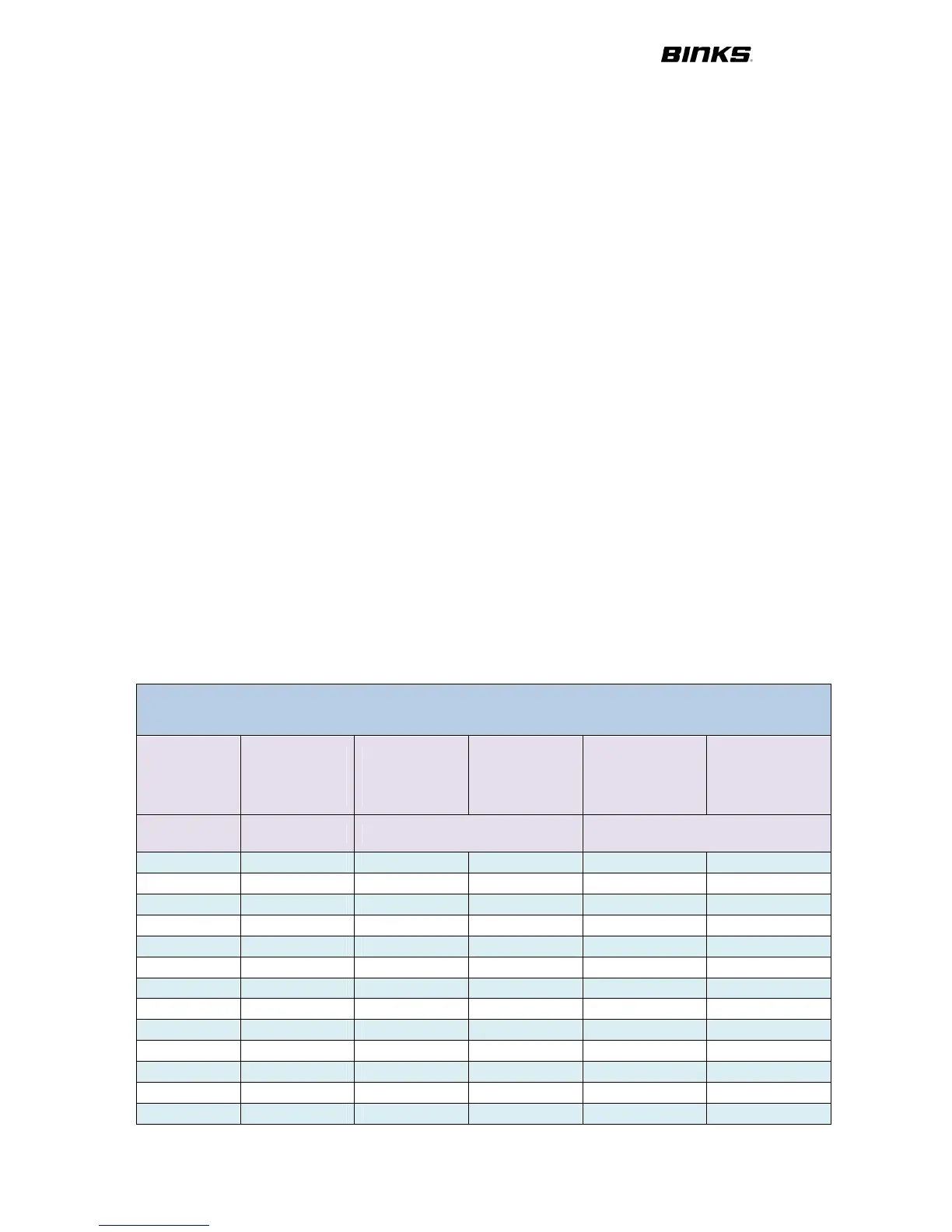

Refer to Fluid Output Table for comparison of fluid output relative to Inverter

frequency and Pump cycle rate.

The return line ‘back pressure’ regulator responds to the changes in system fluid flow

demand, (due to variable paint usage) by dynamically adjusting the paint flow rate

returning to the system paint tank, thus maintaining the set pressure.

Motor Speed Fluid Output Table

Motor

Speed

HZ

Pump

Speed

Cycles/min

Fluid Flow

Rate

Litres/min

Fluid Flow

Rate US

Gall/min

Fluid Flow

Rate

Litres/min

Fluid Flow

Rate US

Gall/min

E2-30 Pump E2-40 Pump

Loading...

Loading...