Instruction Manual

Page 34 of 40 Issue: 2.1

N:\Engineering\Manuals\Pump Unit E2-30 & 40 R2.1.doc

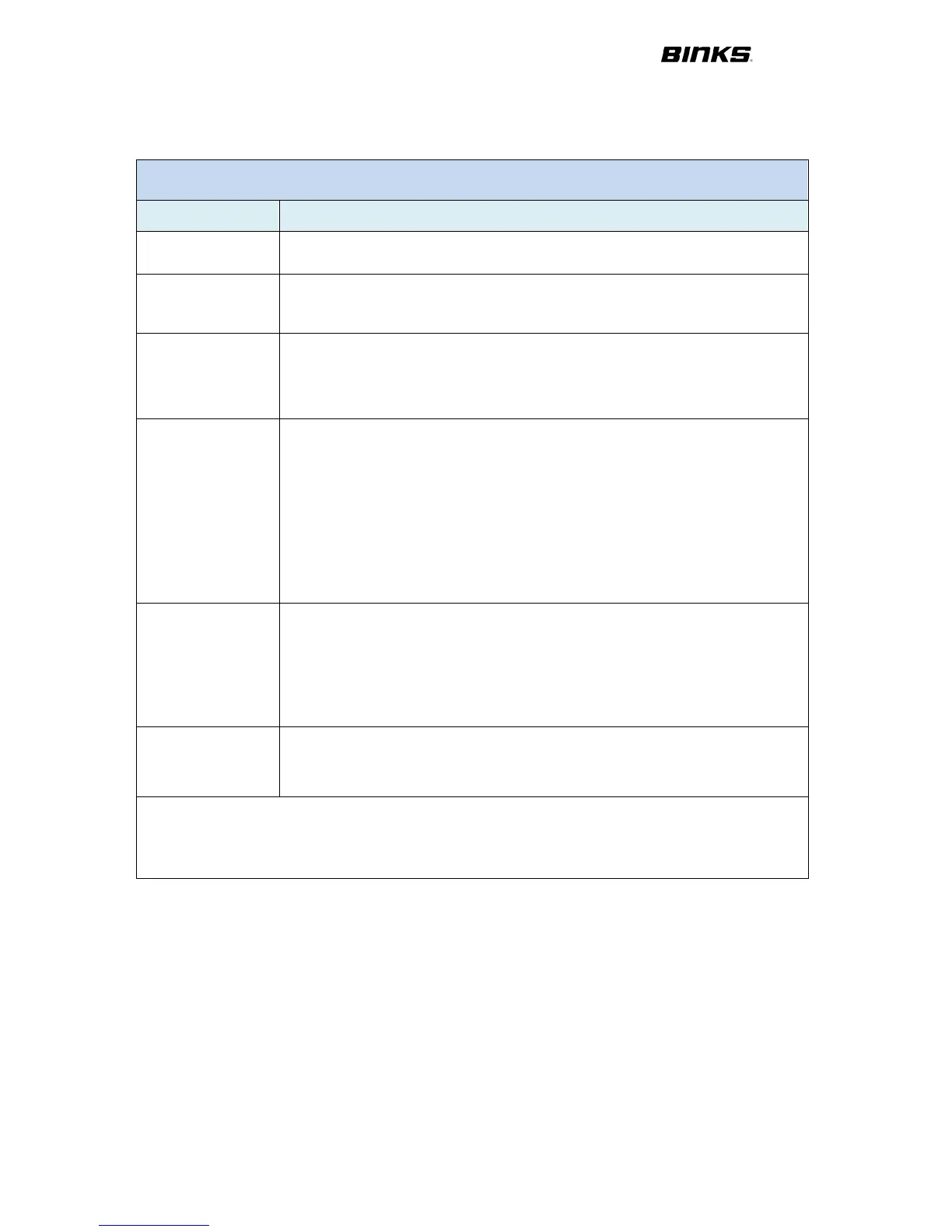

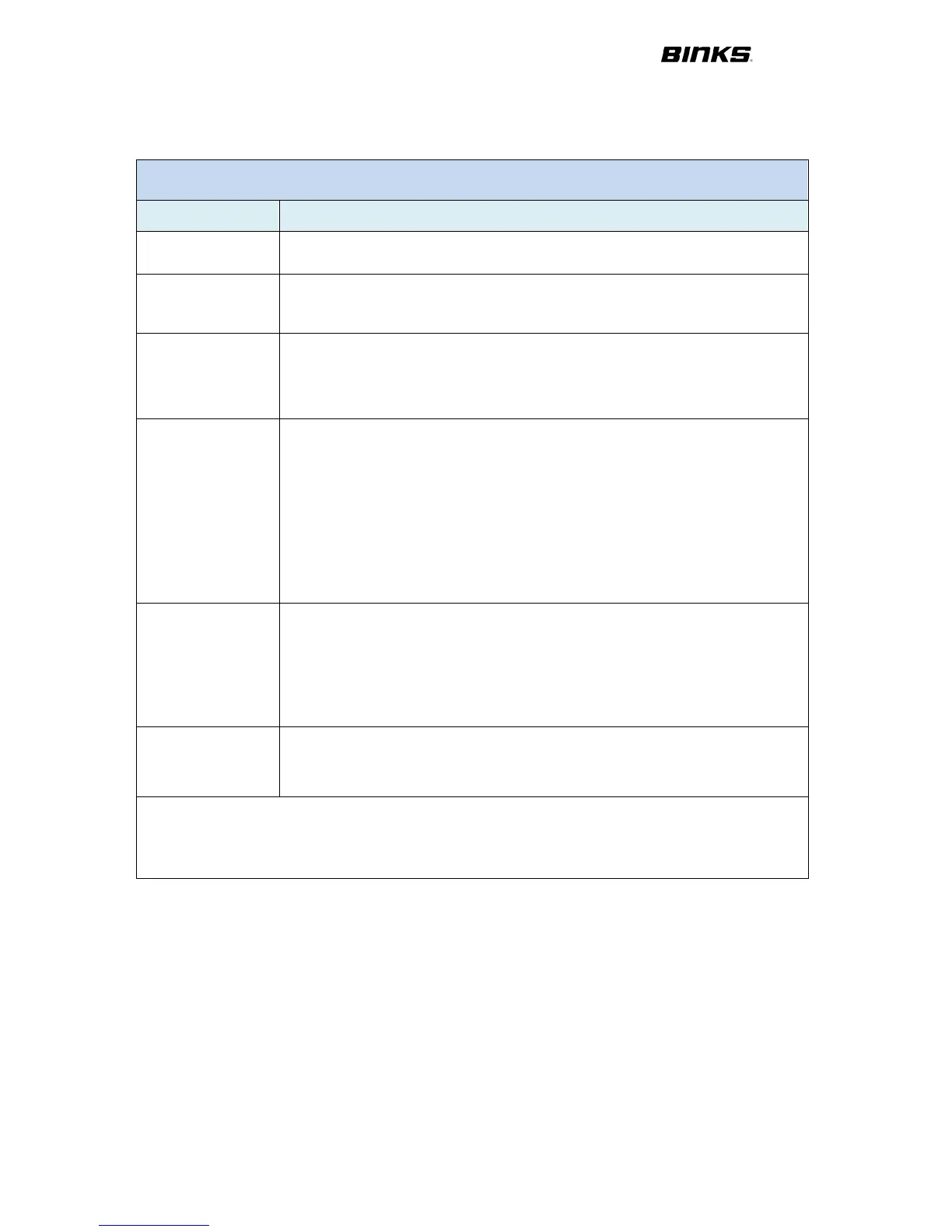

Maintenance – Section 6.2 - General

Maintenance Schedule

Inspection Operation

Daily Check for any fluid leakage.

Weekly

Check for any excessive mechanical noise

Check for excessive fluid pressure pulsation

3 Monthly

Grease Cam Follower Bearings (2 off) with 502375 grease.

while the pump is running. Inject about 8 full strokes from a

standard grease gun fitted with a standard collet connector.

6 Monthly

Grease Linear Bearings (4 off) with 502376 grease. This has to

be done with the pump stopped and isolated. Inject about 15 full

pumps from a standard grease gun fitted with a Hook connector.

Grease Main Shaft Bearing with 502375 grease

Check Gearbox Oil Level.

Inspect Cam and Cam followers for excessive wear, replace if

excessive wear can be seen.

Annually

Inspect Piston and Replace Piston Seals / Bellows / Springs.

Inspect Piston & Outlet Ball Checks, replace as necessary.

Inspect Linear Guide Bearing and Guide Rails for excessive wear.

Replace gearbox oil (per ATEX regulations)

Every 5 Years

Replace main shaft bearings. Linear Guide Bearings, Guide Rails

and Cams if excessive wear can be seen.

Use only 502375 (KP2N-20 DIN 51825) Grease for Cam Follower Bearing.

Use only 502376 (KP2N-40 DIN 51825) Grease for Linear Guide Bearings.

Do not mix the Cam Follower and Linear Guide bearings grease as this will

reduce the operational life.

Maintenance –Section 6.2 - Initial Run Period

Following approximately 1 month running of the pump remove the cover and grease

all bearings. Remove any excess grease and any dust particles present in the cam

area, (Any particles present are from the cam follower tyre, this is a normal function

of the bearing ‘bedding in’ with the cam surface).

Loading...

Loading...