Instruction Manual

Page 31 of 40 Issue: 2.1

N:\Engineering\Manuals\Pump Unit E2-30 & 40 R2.1.doc

Maintenance – Section 6.1 - Assembly Procedure

Fluid Section Assembly [2]

1. Place a shaft / bellows assembly (192679) into the pocket on the back of the inlet

cylinder (82). Hold in position and loosely assemble with 4off M6 x 25 long screws

(109) and washers (108) use loctite 222 on the threads.

2. Lightly lubricate with suitable grease a piston seal (81) and push the seal onto

the piston assembly (192678 or 192754) with the seal lip facing away from the

shaft end of the piston.

3. Apply Loctite 243 to piston shaft thread and loosely screw the Piston assembly

onto the piston shaft. Locate the piston seal (81) into the inlet cylinder (82) (this

will centralize the piston). Hold the piston and prevent from turning with 14 mm

Allen key, tighten the piston onto the shaft with 16mm spanner to 55Nm. Finally

tighten 4 off screws (109) to 12Nm.

4. Locate the outlet cylinder (80) over the piston seal until there is a small gap

between the cylinders.

5. Lightly grease the thread of 4off M12x40 caphead screws (90) and assemble with

4off Ø12 washers (93) to hold the cylinders together. Tighten evenly the caphead

screws in a ‘criss cross’ fashion to 50Nm.

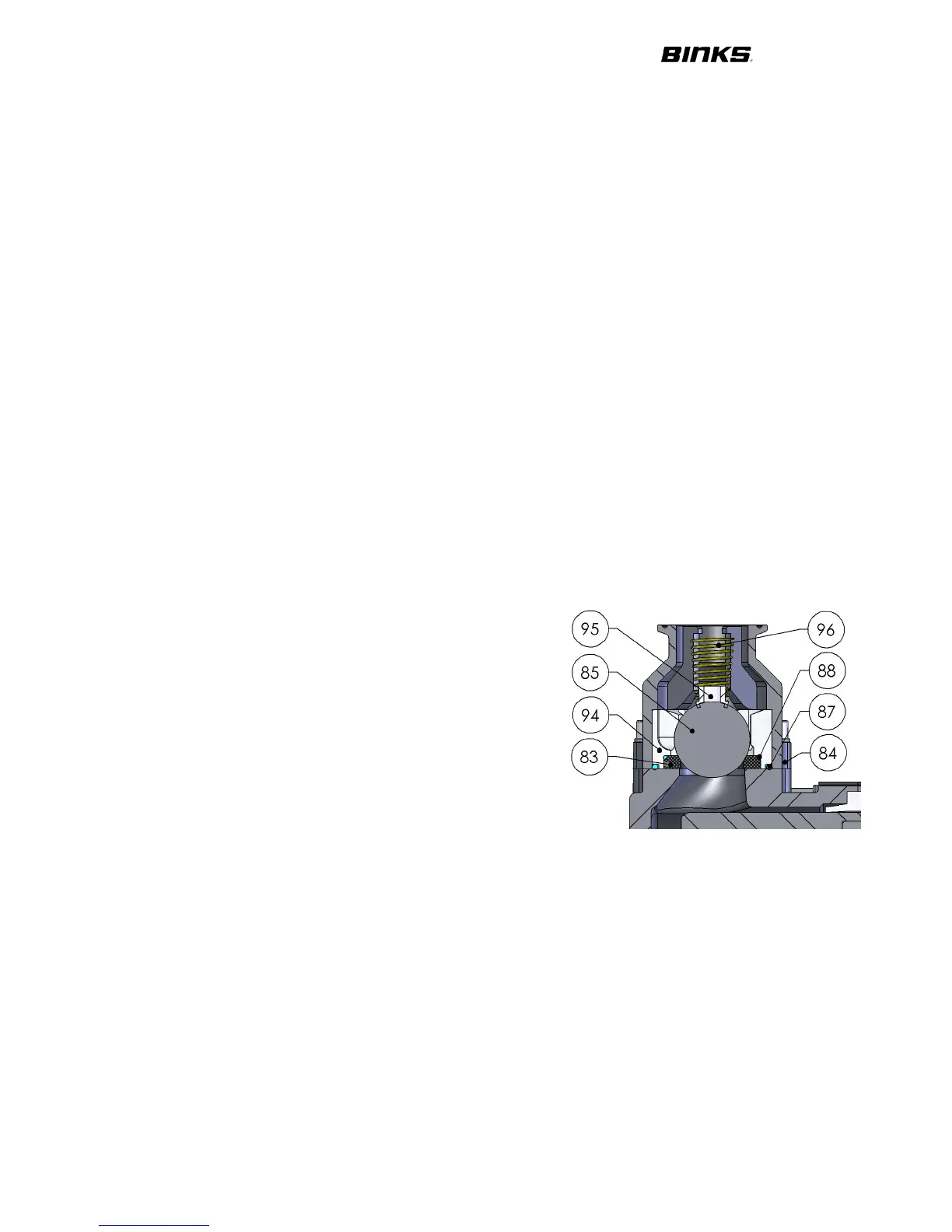

6. Assemble the outlet ball checks:- place spring

(96), spring keep (95) and ball (85) into outlet

check (84)

7. Fit o-ring seal (88) and outlet seat (83) into

outlet cage (94). Fit o-ring seal (87) onto outlet

cage.

8. Fit outlet check and outlet cage assembly

together and position on outlet cylinder (80).

9. Grease threads of 4 off M8x25 caphead screws

(92) and washers (91) and secure. Tighten

evenly to 20Nm.

10. Fit threaded plug (86) with sealing o-ring (89)

Assemble Fluid Sections to Main Drive Assembly

1. Hold a fluid section assembly [2] and feed the piston shaft through the side of the

mechanical assembly casting, locate the bellows spacer into the counterbore in

the casting. Lightly grease thread of 4off M12x40 caphead screws (128) and 8off

Ø12 washers (127) to hold the cylinders to the side plate. Tighten all caphead

screw to 25Nm in ‘criss cross’ fashion and then to 50Nm

2. Pull the piston shaft until the shaft and the carriage adaptor are touching. Fit the

quick release shaft clamp (48) and tighten to 20Nm

Loading...

Loading...