Instruction Manual

Page 33 of 40 Issue: 2.1

N:\Engineering\Manuals\Pump Unit E2-30 & 40 R2.1.doc

Maintenance – Section 6.2 - General

The working life and thus the expected life prior to replacement of parts within a Paint

Pump are greatly affected by three main factors: -

• Abrasiveness of Fluid Pumped

• Pump Duty Cycle

• Fluid Pressure Output requirement

The two components which are more greatly affected by the above criteria than any

other components in the pump are: The Main piston Seal and the Cam Follower ; it is

therefore recommended that these two items are stocked as spare parts in addition

to the recommended spare parts kits.

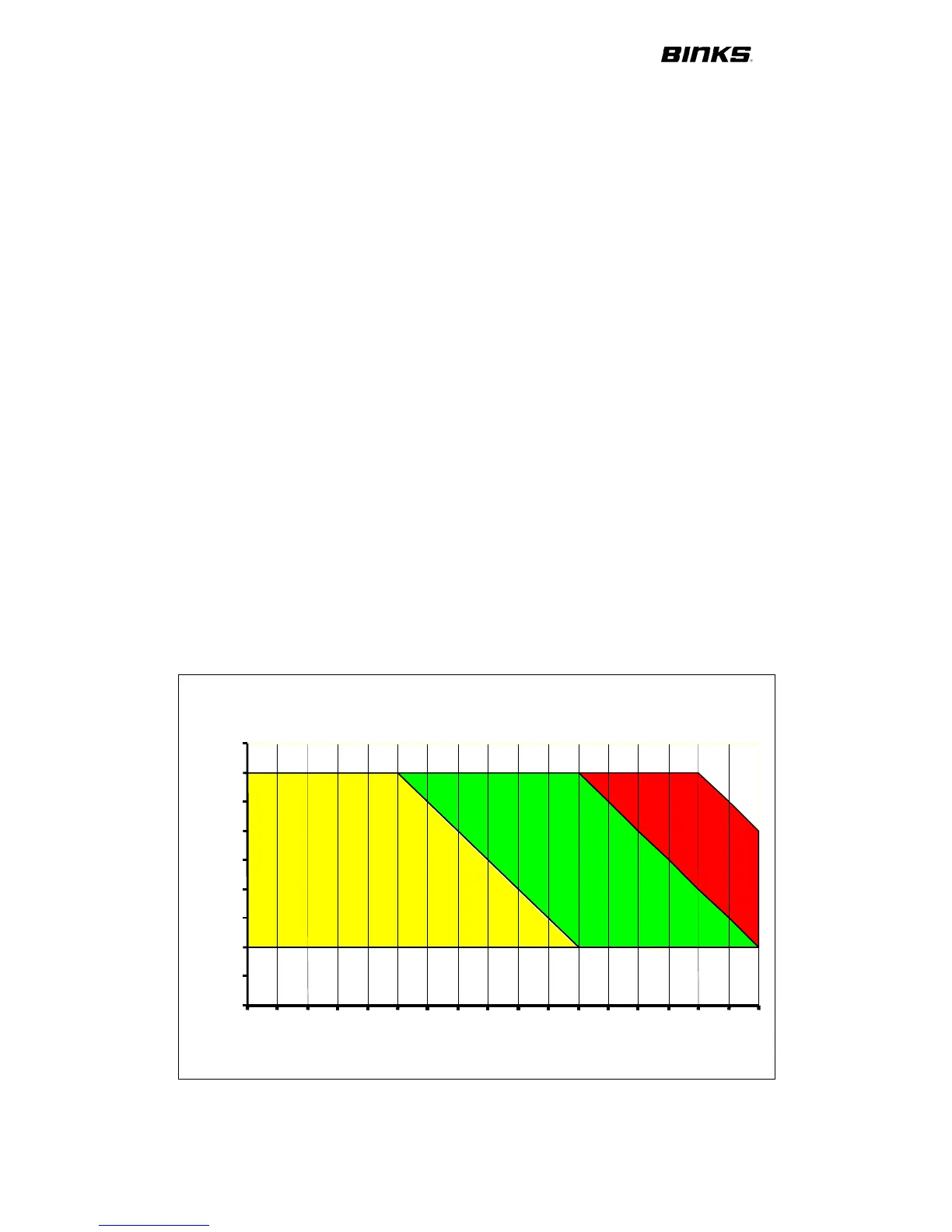

It is also a requirement of the E.U. ATEX directive (Use of Equipment in Potentially

Explosive Atmospheres) that any Bearings should be replaced when they have

reached 90% of their calculated operational life. The following chart is included as a

helpful guide, as the working life of the Cam Follower bearings used in the Pump is

greatly dependant upon the Duty Cycle and Fluid Pressure Output Requirement.

Before any maintenance always switch off the pump and secure against any

unintentional start up.

Loading...

Loading...