Instruction Manual

Page 28 of 40 Issue: 2.1

N:\Engineering\Manuals\Pump Unit E2-30 & 40 R2.1.doc

Maintenance – Section 6.1 - Assembly Procedure

192682 Carriage Sub-Assembly

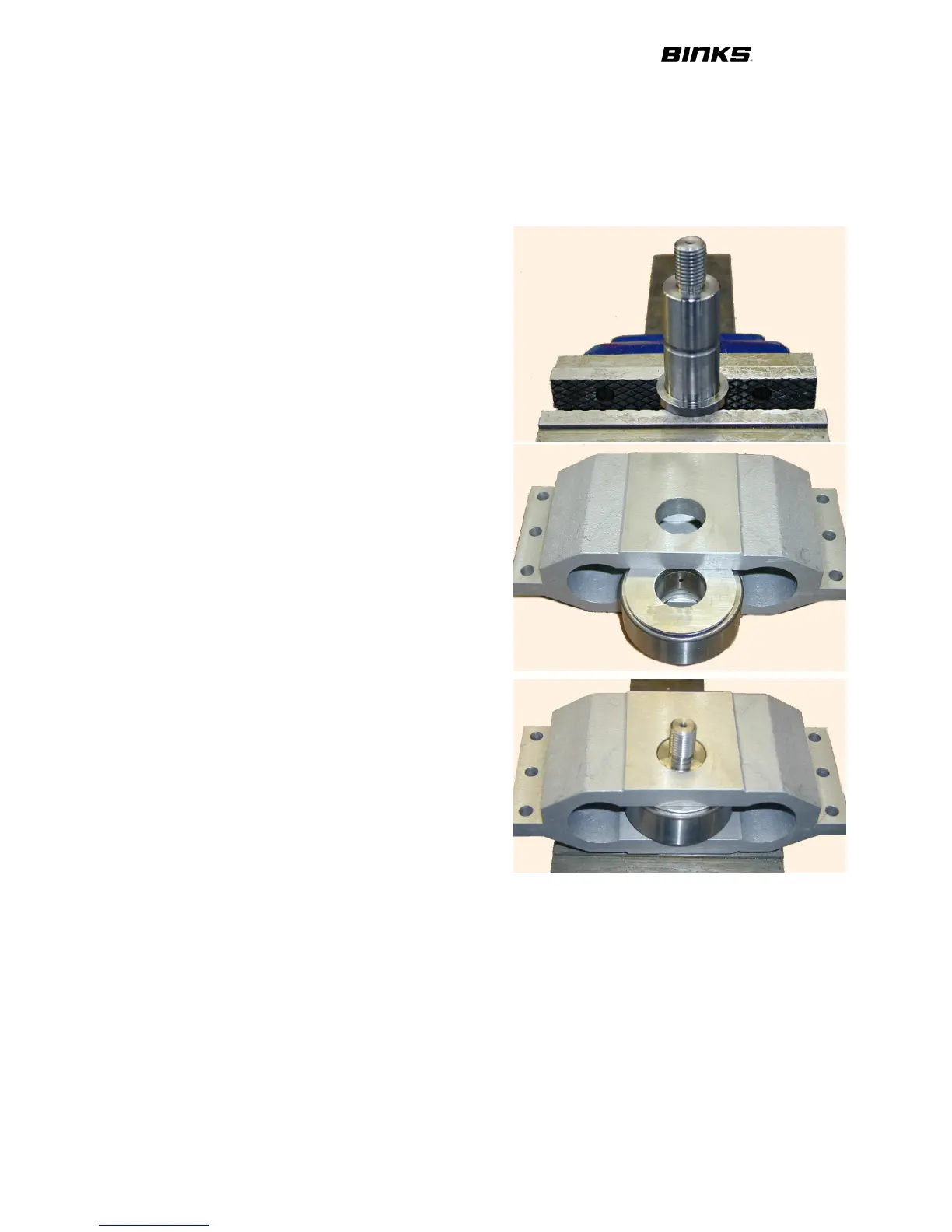

1. Place cam follower pin (65) into a vice

gripping the hexagon end so that the

pin is vertical and the grease cross

hole points towards the back.

2. Place cam follower bearing (67) and

one follower washer (64) each side of

bearing into middle carriage (61) so

that the bearing cross hole faces to the

back of the block.

3. Place this loose assembly over the

pin, so that the two cross holes line up.

Place nut washer (66) and lightly

greased nut (74) onto the pin. Hold in

position and tighten the nut to 80 Nm.

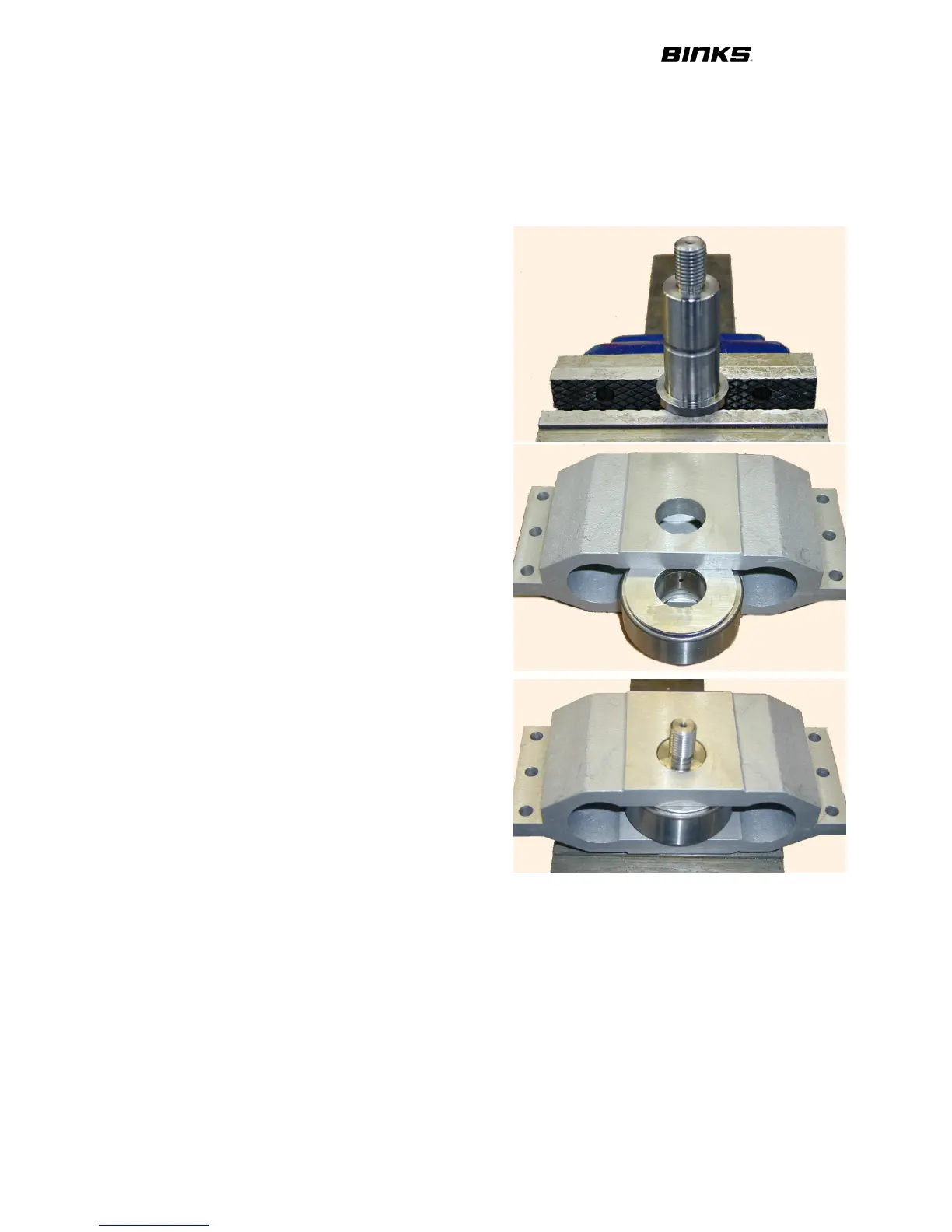

4. Place the carriage adaptor (63) in the

block recess and fit 2 off screws (73)

with Loctite 222 on the threads.

Tighten screws to 22 Nm

5. Fit the 2 off Ø6 pushin elbows (76) into the cam follower pin grease ports and

position to face the rear of the pump.

6. Assemble carriages together: - Connect 1 off LH and 1 off RH end blocks to

the middle carriage (61) with 3 off per side M8 x 25 cap head screws (72) &

spring washers (71) with thread lock Loctite 222. Leave the sub-assembly

loose. (2 off assemblies are required.)

Loading...

Loading...