Biodom C15 | instructions for use, maintenance and installation | February 2019

25

6.3. INSULATION AND DIAMETER OF HOLES IN THE ROOF

Once the position of boiler installation is determined, a hole for passage of smoke pipes must be made.

This changes in regard to the type of installation, diameter of smoke pipes and type of wall or roof,

through which it must be guided. Insulation must be of mineral origin (rock wool) with nominal density

greater than 80 kg/m³.

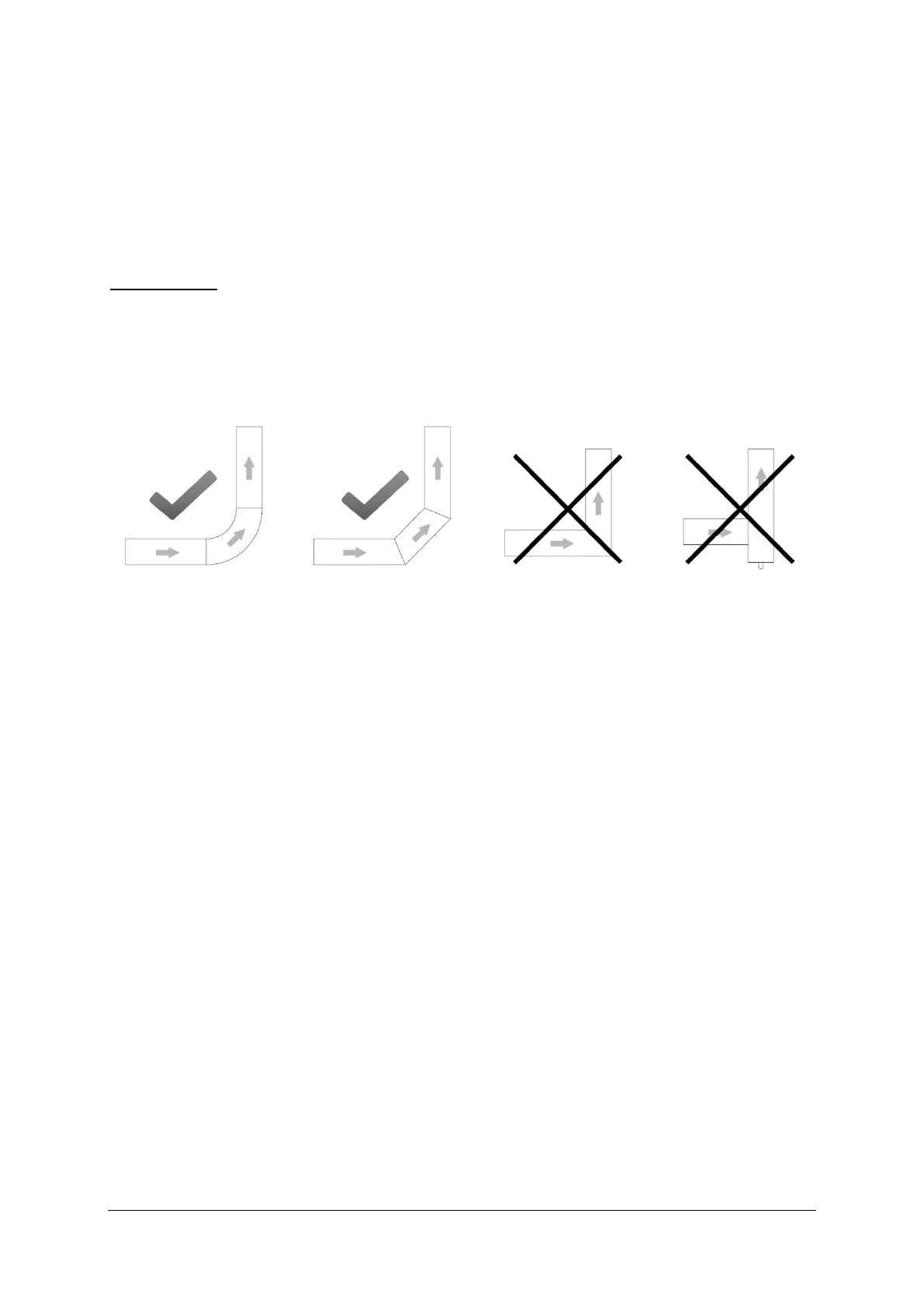

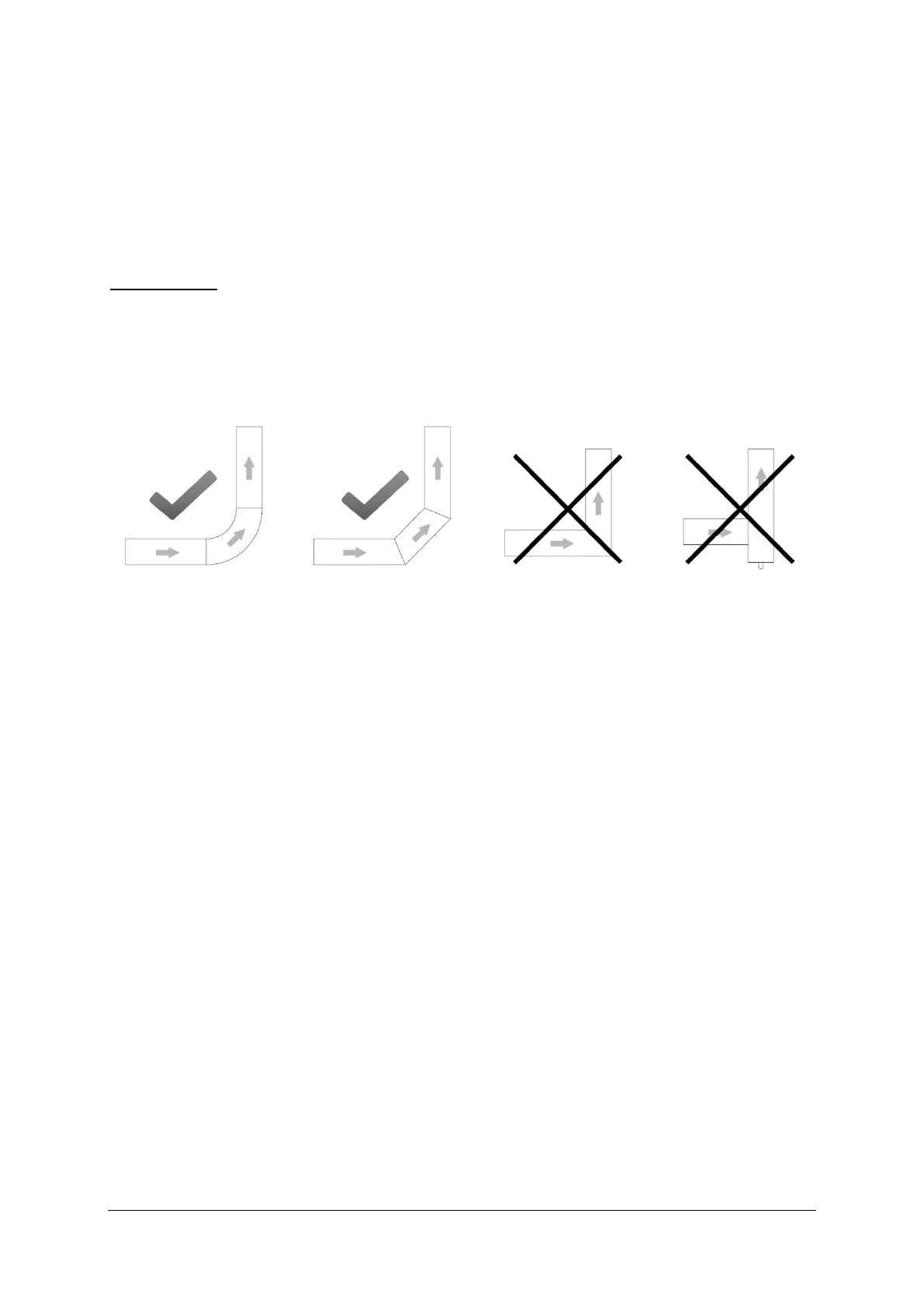

Perfect draught depends mostly on flue pipe, which must be free of obstructions, such as bottlenecks

and/or various joint connections. Joint must be at an angle of 30°, 45° and 90°. Joints at an angle of 90°

must be made of three parts (figure 6).

In any case, it is mandatory to provide an initial vertical straight pipe of 1,5 metres in length (minimum)

to ensure correct extraction of smoke gases.

Figure 6

6.4. INLET AIR

Air from the environment, required for correct combustion, must be refreshed with new air, through

opening in the wall, slot in boiler room doors or grid on the window. This will ensure proper combustion

and proper boiler operation.

Opening for intake of fresh air must also be fitted with protective slot against rain, wind and insects.

Hole must be made on the external wall of the space, where the pellet boiler is installed.

Standard UNI 10683 prohibits intake of inlet air from storage of flammable materials or spaces with

the risk of fire.

If there are other combustion devices in the room, a sufficient amount of air must be ensured, which

is required for proper combustion of all combustion devices, and regard all technical properties of

already installed ventilation systems in the boiler room.

Loading...

Loading...