CB-100-218

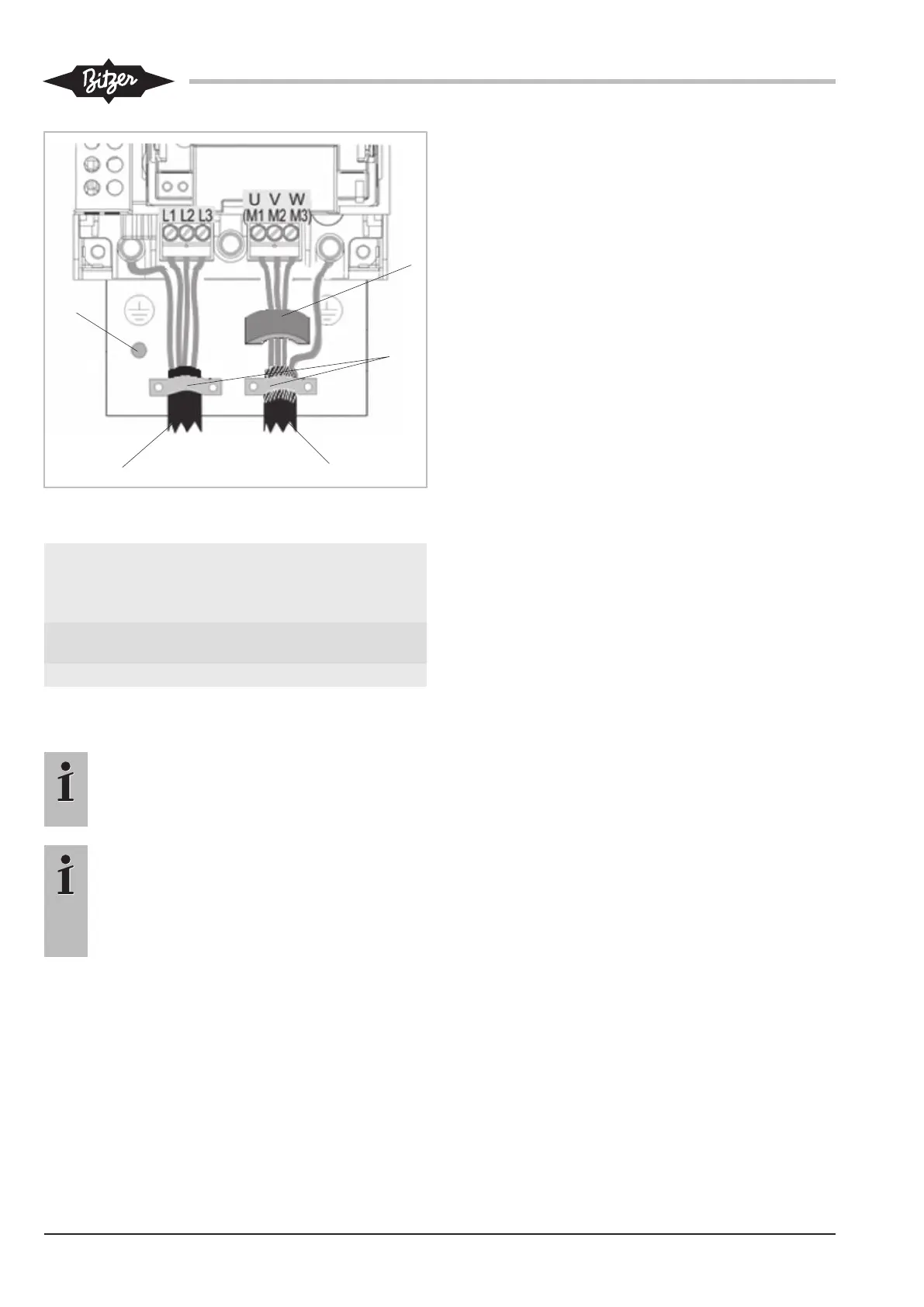

Fig.11: Power connections (voltage supply cable and motor cable)

with fixture

A Earth connection B voltage supply

cable / terminals for

nominal supply

voltage

C Motor cable / motor

terminals

D Cable clips

E Ferrite core

5.3 Control connections (inputs and outputs)

Information

To meet the EMC and safety requirements, the

control module must be connected to the pro-

tective earth conductor outside the device!

Information

The entire external wiring must be approved for

maximum system voltage!

All control and signal terminals guarantee safety

extra low voltages (SELV), i.e., they are protec-

ted by double insulation.

Specification of the control connections:

• Cables completely without or with non-insulated wire

end sleeves: 0.25..1.5 mm².

• Cables with insulated wire end sleeves: 0.25..0.75

mm².

Digital inputs

• Function

– X13:2:DI1 (Start)

Compressor start command.

– X13:3:DI2 (Force)

Operation of the compressor at a minimum fre-

quency of 50Hz.

– X13:4:DI3 (p01 → 2)

External control: without function.

With extension module: Switch over from evapor-

ation temperature setpoint 1 to 2.

– X12:1:DI4 (pc1 → 2)

External control: without function.

With extension module: Switch over from con-

densing temperature setpoint 1 to 2.

– X12:2:DI5 (Reset)

Reset of faults.

– X12:3:DI6 (Detection)

Automatic detection of the extension module.

• Technical data

– Status:

Off: 0..5V DC

Undefined: 5..15 V DC

On: 15..24V DC

– Max. input voltage: ±30V DC

– Input impedance: 3,3kΩ.

– Input current: 7.3mA ±10% at 24VDC

– Common on X10:4

Analogue inputs

• Function

– X11:1:AI1 (mA/p0)

External control: Setpoint as 4..20mA signal.

X10: 2: Common

With extension module: Input for low pressure

coming from the extension module (→X11:1)

– X11:2:AI2 (V/pc)

External control: Setpoint as 0..10 V signal

X10: 2: Common

With extension module: Input for high pressure

coming from the extension module (→X11:2)

• Technical data

– Input signal: 0..10V or 4..20 mA

Loading...

Loading...