Page 11 3BE390691NM – 10/10

BONNET GRANDE CUISINE

Registered Office:

Rue des Frères Lumière - Z.I Mitry Compans

77292 MITRY MORY Cedex

4.3 GAS FLOW RATES AND POWERS

See paragraph 1: Technical characteristics (installation manual)

4.4 CHART OF NOZZLES

4.4.1 BEFORE OCTOBER 6TH, 2010 : TO N° P27516281C

6 and 10 level ovens

GASES NOZZLES Air

Regulating

Designation Pressure

Qty Diameter

Code Marking Adjust.

valve

Family Type

(mbar)

(1/100

e

)

(stamped)

d (stamped)

G20 20 1 8.5 368 551

- 3.5 147 772 Natural gas

G25 20 or 25 1 No nozzle - 2.6 147 772

G31 30 or 37 4.6 147 773

or 50

1 5.7 368 550

1 groove

Burner

G.P.L.

G30 30 or 50 1 5.7 368 550

1 groove 9.2 147 773

20 level ovens

GASES NOZZLES Air Regulating

Designation Pressure

Nbre

∅

∅∅

∅

Code Marking

adjust

valve

Family Type

(mbar)

dry (1/100

e

)

(stamped)

d (stamped)

G20 20 2 8.5 368 551

- 3.5 147 772 Natural

gas

G25 20 or 25 2 No nozzle - 2.6 147 772

G31 30 or 37 4.6 147 773

or 50

2 5.7 368 550

1 groove

Burner

G.P.L.

G30 30 or 50 2 5.7 368 550

1 groove

9.2 147 773

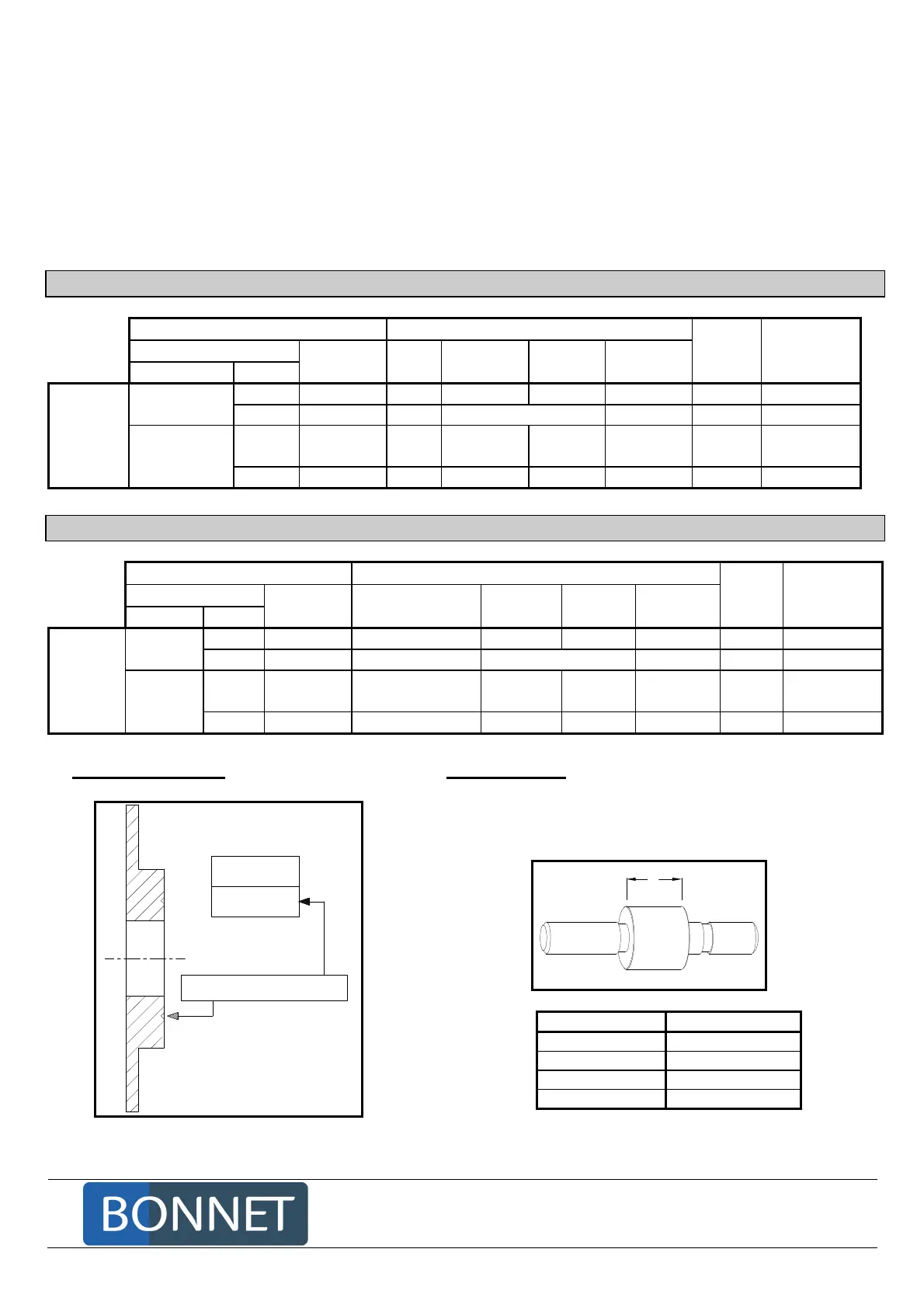

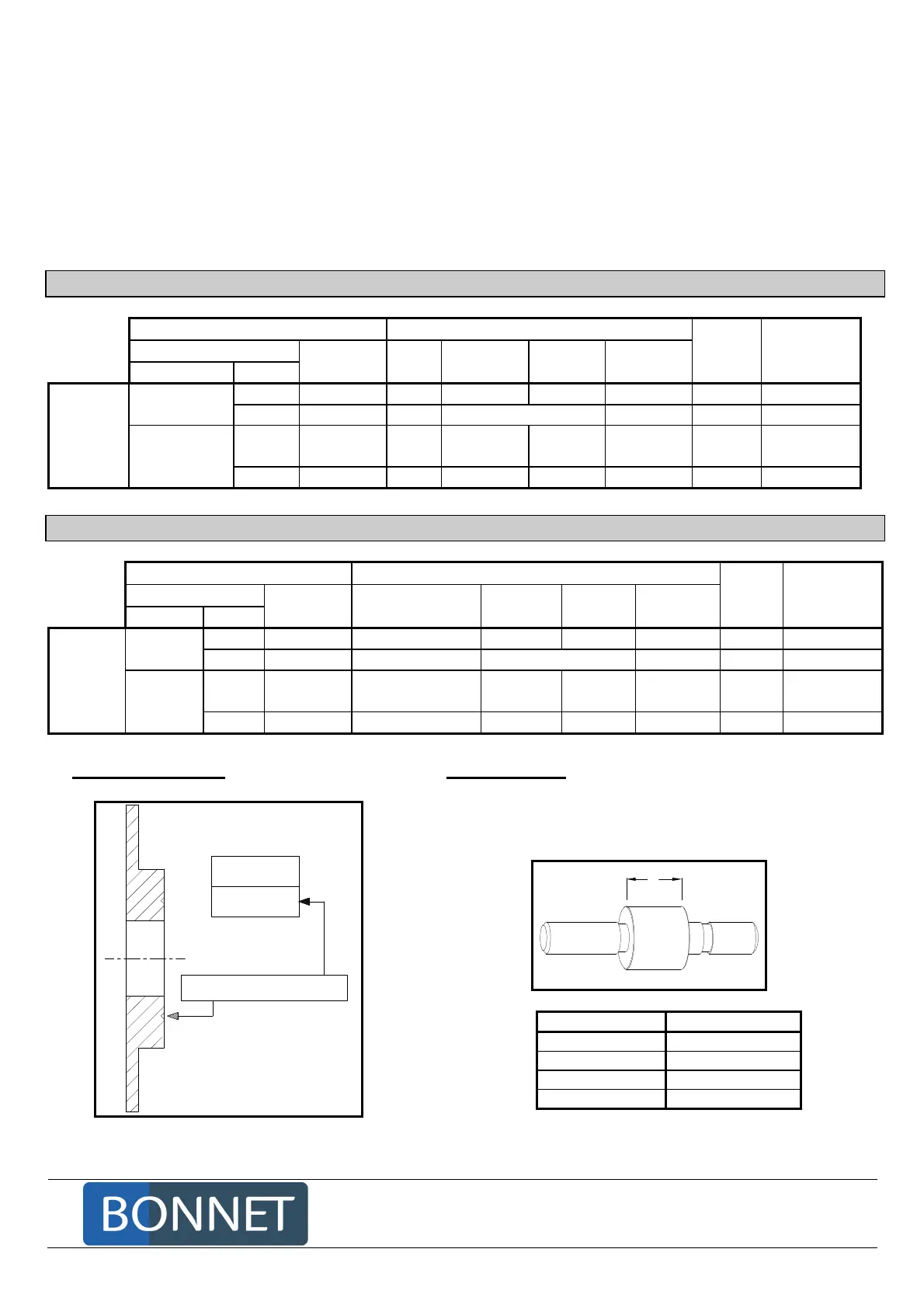

Marking of nozzles

Air adjustment

Air adjustment is carried out by means of a distancing

ring with a d size specified in the previous chart.

d

d Code

2.6 368 603

3.5 368 604

4.6 368 605

9.2 368 606

1 groove on injectors Ø 5.7

Ø = 8.5 mm

Code: 368 551

Ø = 5.7 mm

Code: 368 550

Loading...

Loading...