EN

18

Installation

www.bora.com

4.4.4 Special assembly instructions for gas

cooktop CKG

XX

Please note the local regulations and connection requirements

applicable to gas cooktops.

XX

Before connecting the appliance, check that the appliance

settings comply with local connection requirements

(gas type and pressure).

i

Minimum requirement for operating gas cooktop CKG:

System software 03.00 (or higher)

XX

If necessary, retrieve the installed software version

(see operating instructions, Menu chapter, Retrieving the

software version).

XX

Update the system software if necessary (see operating

instructions, Menu chapter, Updating the system software).

i

Minimum clearance of 650mm between the worktop and

wall unit in the case of gas devices.

i

On recirculation systems, a return flow aperture of at

least 1,000 cm² must be provided for each air cleaning

unit.

i

Ensure sufficient ventilation.

i

Taking into account the applicable valid regulations,

the cooktop must be connected to the gas line with an

upstream stopcock.

i

The gas supply pipe can be connected after the gas

cooktop has been installed.

i

The hose connection must be laid in such a way that it is

not subject to deformation, buckling or abrasion.

i

The stopcock and gas supply pipe connections must be

accessible.

i

It must be possible to inspect the entire length of the

hose line once installed.

i

Only compatible connection pieces are to be used for the

hose line.

i

The pressure regulator must correspond to the set gas

type and set gas pressure and must meet local and legal

requirements.

i

The gas connection hose line must not come into contact

with smoke or the flue outlet of an oven.

i

The hose line must not come into contact with hot

surfaces on the cooktop or other devices.

i

The gas hose must be inspected every 5 years and

replaced if necessary. The gas hose must meet the

requirements of EN14800.

4.4.3 Recirculation when using the cooktop

extractor as a recirculation system

In the case of recirculation systems there must be a return flow

aperture in the kitchen units:

XO

> 500 cm² (per air cleaning box) in combination with cooktops

CKFI, CKI, CKIW, CKCH, CKCB and CKT

XO

> 1000 cm² (per air cleaning box) in combination with gas

cooktop CKG

i

If several extractor systems are operated in recirculation

mode, the return flow aperture for each air cleaning box

must be calculated correspondingly. Example:

2 recirculation systems = 2 x (> 500 cm²) or

2 x (> 1,000 cm²) in the case of gas appliances

For recirculation, the necessary return flow aperture can be

created using a shortened plinth. A slatted plinth with at least

the minimum opening cross-section can also be used.

XX

Ensure that the return flow aperture is large enough.

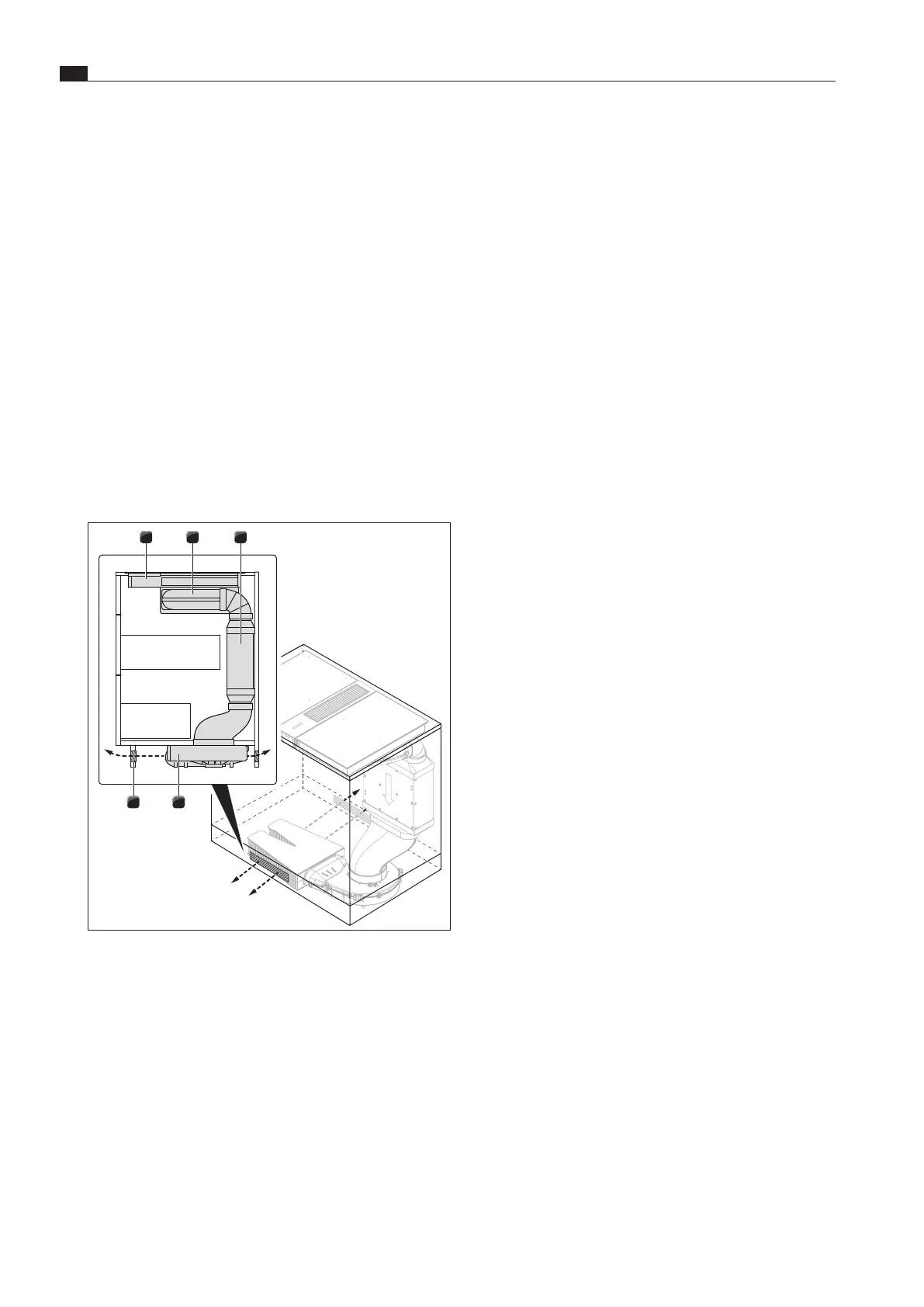

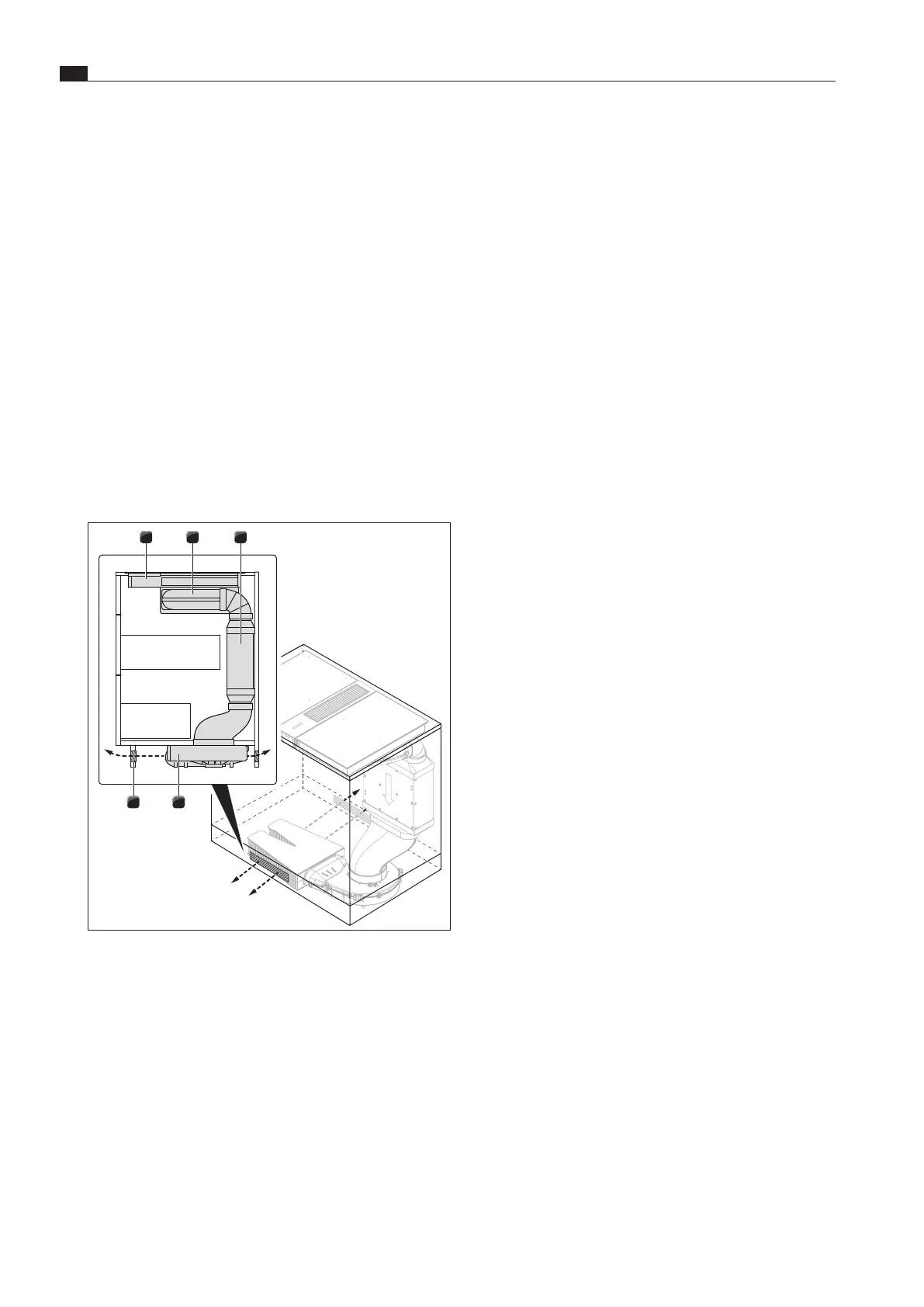

45

1 32

Fig. 4.4 Recirculation design example (kitchen island +

cooktop + CKA2//CKA2AB + air cleaning unit)

[1] Cooktop

[2] Cooktop extractor CKA2/CKA2AB (recirculation)

[3] Air cleaning unit (ULB1, ULB3, ULBF)

[4] BORA plinth fan EC (ULS)

[5] Recirculation return flow aperture

(Total opening cross section per air cleaning unit ≥500 cm² or

≥1000 cm² in the case of gas cooktop CKG)

i

If the gas flame goes out, is excessively affected by the

extractor and/or the flame is not as it should be (e.g.

soot production, flame blowback, etc.), the return flow

aperture must be enlarged.

Loading...

Loading...