Safety Devices and the UPM Controller Overview

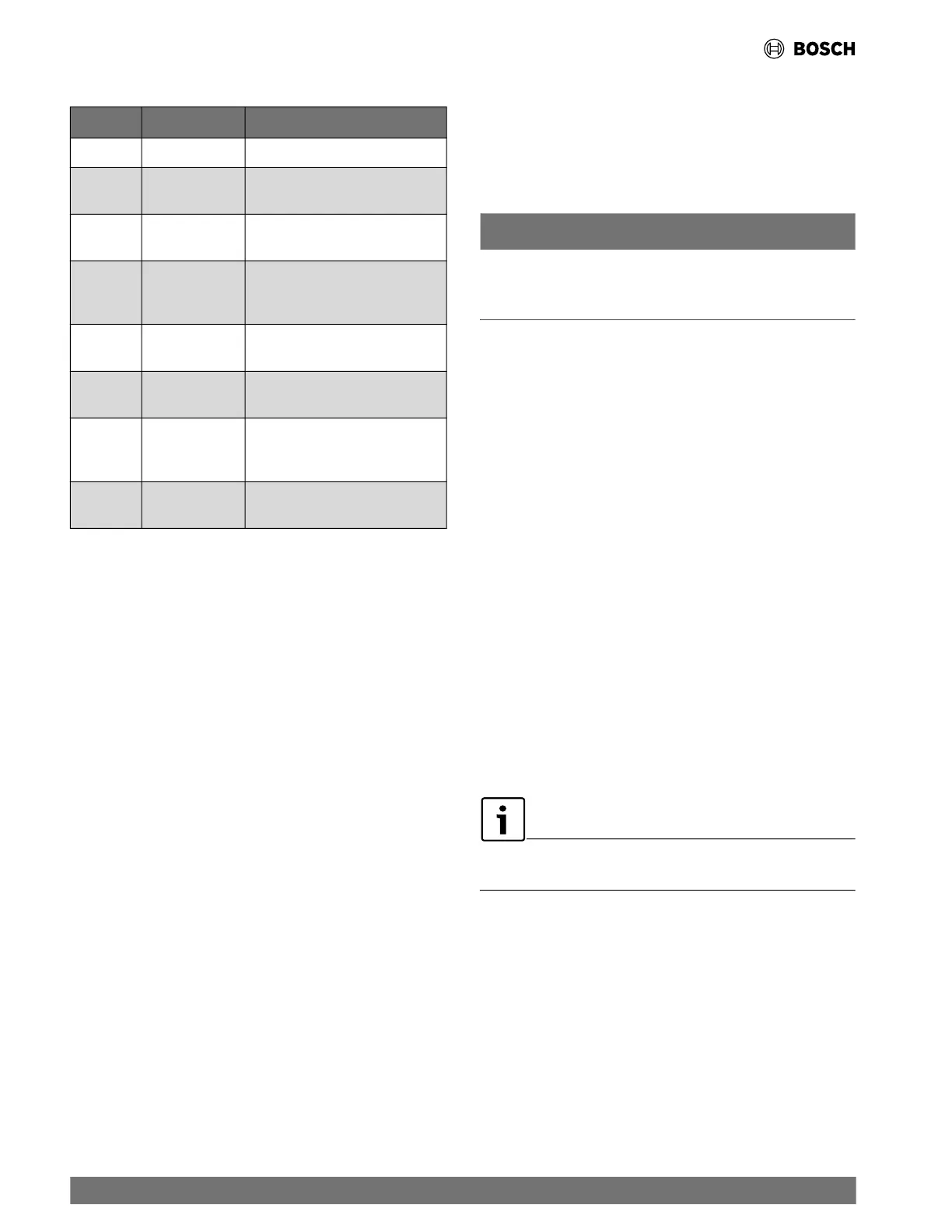

Table 10 UPM Fault Blink Codes

Blinks Fault Fault Criteria

None None All fault conditions normal.

1 High Pressure

Refrigerant discharge pressure has

exceeded 600 PSIG.

2 Low Pressure

Refrigerant suction pressure has

fallen be

low 40 PSIG.

3

Water Coil Freeze

Condition

Refrigerant temperature to the water

coil has fallen below 25°F for 120

seconds.

4

Condensate

Overflow

Co

ndensate levels in the unit drain

pan are too high.

5 Brown Out

Control voltage has fallen

below 18 VAC.

6

Air Coil Freeze

Condition

Refrigerant temperature to the air coil

has falle

n below 25°F for 120

seconds.

7

Refrigerant Leak

Fault

Refrigerant LFL% is more than 15%.

• FREEZE SENSOR: The default setting for the freeze limit

trip is 25°F (FREEZE 1); however, this can be changed to

15°F by flipping the DIP switch position “5” (

Refer to Fig.

18, item [10]) (

Refer to Fig. 21), freeze limit trip should

only be changed to 15°F when a closed loop system with

appropriate antifreeze mixture is used. Since Freeze Sensor

2 is dedicated to monitoring the load side coil, it is

recommended to leave the factory default setting on the

board. The UPM controller will constantly monitor the

refrigerant temperature with the sensor (FREEZE 1)

mounted close to the condensing water coil between the

thermal expansion valve and the water coil. If the

temperature drops below or remains at the freeze-limit trip

for 120 seconds, the controller will shut the compressor

down and enter into a soft-lockout condition. Both the status

LED and the alarm contact will be active. The status LED will

be active, blinking the fault code. The LED will flash (three

times) the code associated with this alarm condition. If this

alarm occurs two times (or four if DIP switch position “1” is

set to “ON”) within an hour, the UPM controller will enter into

a hard-lockout condition. It will constantly monitor the

refrigerant temperature with the sensor (FREEZE 2)

mounted close to the air coil between the thermal expansion

valve and air coil, as shown in Fig. 20. If the temperature

drops below or remains at the freeze limit trip for 120

seconds, the controller will shut the compressor down and

enter into a soft-lockout condition. Both the status LED and

the alarm contact will be active. The status LED will be active,

blinking the fault code. The LED will flash six times the code

associated with this alarm condition. If this alarm occurs two

times (or four times if DIP switch position “1” is set to

“ON”)(

Refer to Fig. 21)(See Table 9) within an hour, the

controller will enter into a hard-lockout condition.

NOTICE

The freeze sensor (FREEZE 1) will not guard against the loss of

water. A flow switch is recommended to prevent the unit from

running if water flow is lost or reduced.

• INTELLIGENT RESET: If a fault condition is initiated,

the five-minute delay on break time period is initiated and the

unit will restart after these delays expire. During this period

the fault LED will indicate the cause of the fault. If the fault

condition still exists or occurs two or four times (depending if

the Lockout DIP switch position “1” is set to “OFF” or “ON”)

(

Refer to Fig. 21)(See Table 9) before 60 minutes, the

unit will go into a hard lockout and requires a manual lockout

reset.

• LOCKOUT RESET: The method to exit a hard lockout

depends of the Reset DIP switch setting:

— To clear a hard lockout when the DIP switch position “2”

is set to “OFF” (Y), power can be cycled OFF then back

ON either at the unit’s thermostat or at the circuit

breaker.

— To clear a hard lockout when the DIP switch position “2”

is set to “ON” (R), power must be cycled OFF then back

ON at the circuit breaker (not at the thermostat).

(

Refer to Fig. 21.) (See Table 9.)

The blower motor will remain active during a lockout

condition.

• PUMP DIP SWITCH: When DIP switch position “7” is set

to “ON” and no Y call has been received in the past 8 hours,

the compressor will have a delay of 30 seconds to allow a

loop pump to circulate water before compressor starts.

(

Refer to Fig. 21.) (See Table 9.)

34 |

CL Series Heat Pumps — 8733838716 (2024/05)

Loading...

Loading...