37

Compound Cuts

A “compound cut” is a cross-cut made with the

blade both at a miter angle and at a bevel angle.

Because it may take several tries to obtain the

desired compound angle, perform test cuts on

scrap material before making your cut.

FOLLOW THESE INSTRUCTIONS FOR MAKING

YOUR COMPOUND CUT:

1. Extend the left base extension and left sliding

fence (See “Sliding Fence and Base Extension”

on pages 30 and 31)

2. Properly position workpiece. Make sure

workpiece is clamped firmly against the table or

the fence (figure 43).

Use clamping position that

does not interfere with

operation. Before switching on, lower head

assembly to make sure clamp clears guard and

head assembly.

Be aware of the path of the

saw blade. Make a dry run

with the saw Off by conducting a simulated

cutting cycle, and observe the projected path of

the saw blade. Keep hands at least six (6) inches

away from the projected path of the saw blade.

3. Set miter and bevel angles according to the

instructions on page 35 and 36 for miter and

bevel cuts.

4. Follow the procedures for chop cut or slide cut.

5. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Cutting crown molding flat on the table requires

compound cuts. See cutting crown molding

section on page 39.

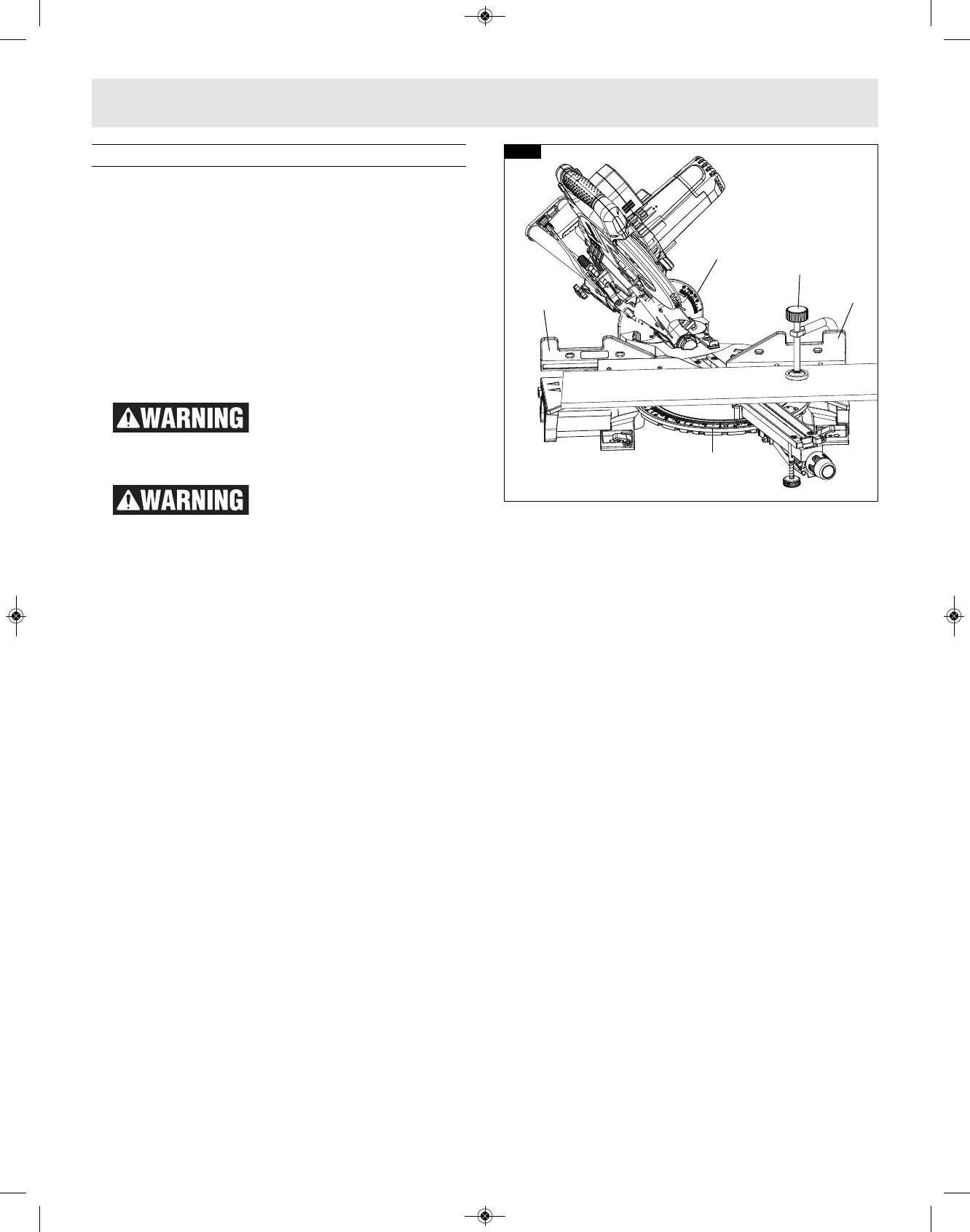

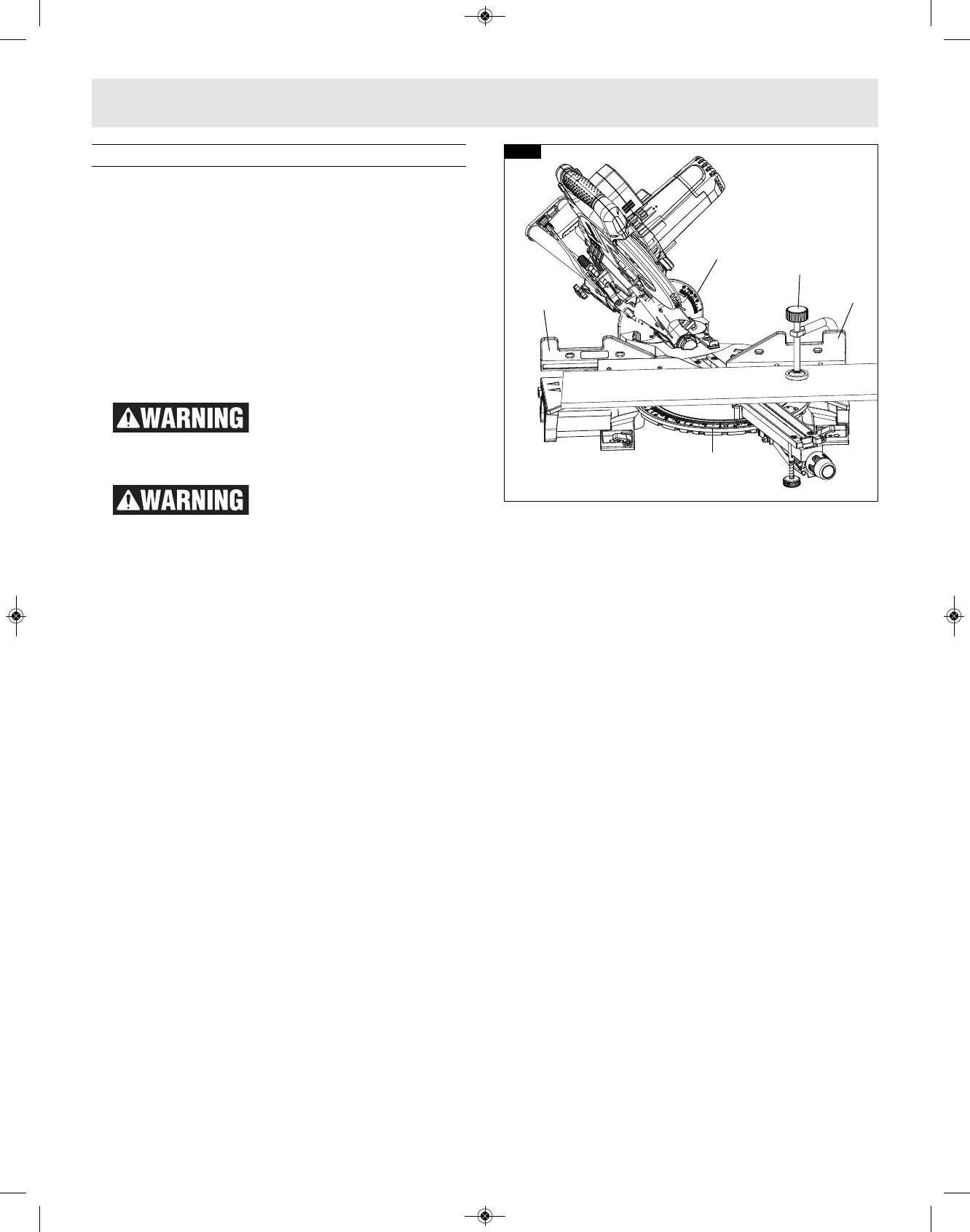

Bevel

Scale

Clamp

Left

Sliding

Fence

Miter Scale

Right

Sliding

Fence

FIG. 43

Saw Operations

Loading...

Loading...