36

Bevel Cuts

A “bevel cut” is a cross-cut made with the blade

perpendicular to the fence and with the table set

a

t 0° miter. The blade can be tilted at any angle

within the saw’s range: 47° left and -2° right from

the vertical.

T

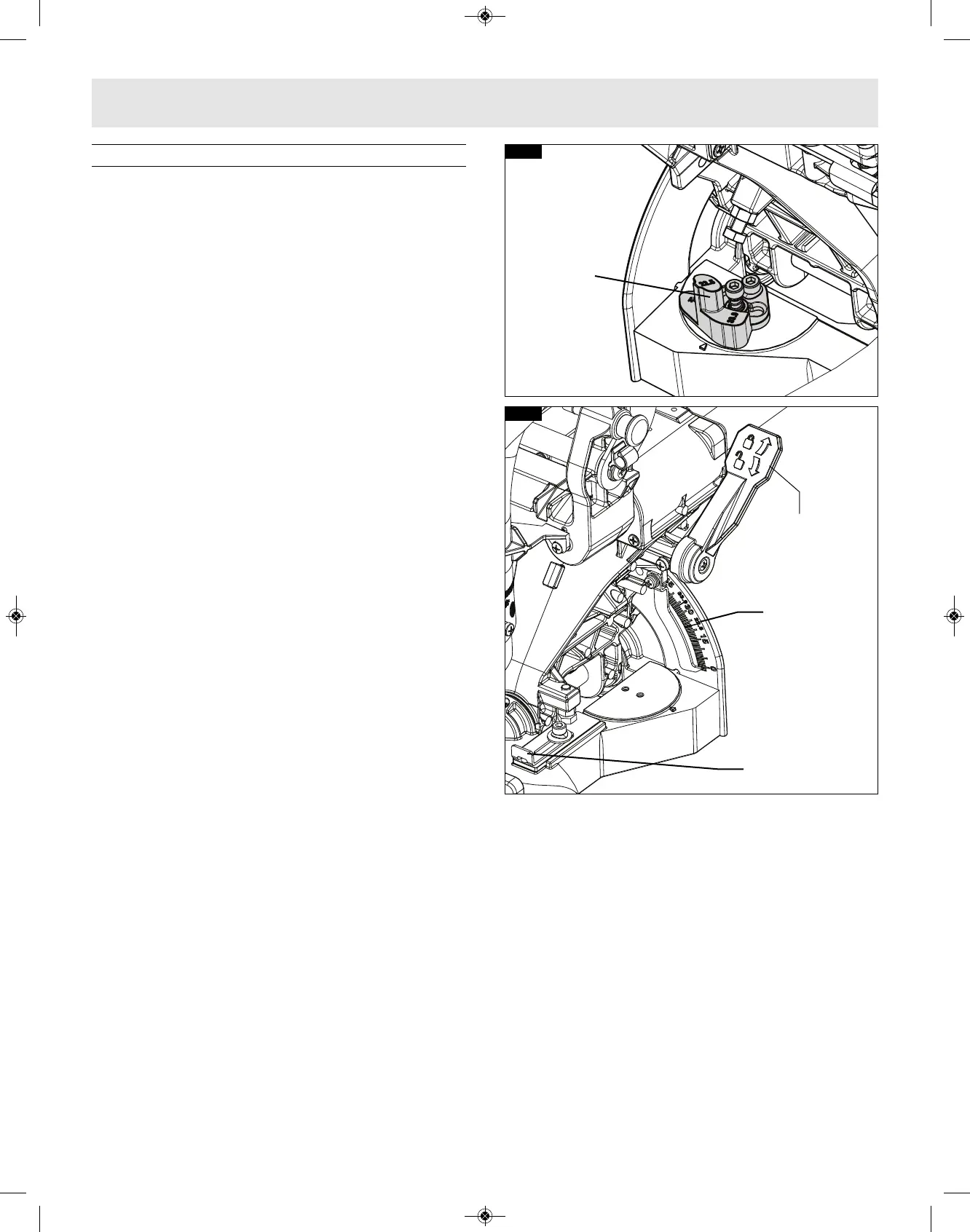

he bevel scale is sized and positioned for easy

reading. And the side bevel lock lever is to lock and

unlock the various settings.

A rotating Left Bevel Stop indicator allows you to

set the most common bevel stops 0°, 22.5°, 33.9°,

45° and 47° Left, (figure 41). The 33.9° bevel stop

is for cutting 38° “spring angle” crown molding flat

on the table. (See Compound Cuts for more

information.)

A -2° Right Bevel Stop is also available for back

cutting applications. Simply slide this stop forward

and back to engage the 0° stop and disengage for

-2° stop. (see figure 42)

SETTING THE SAW TO MAKE A BEVEL CUT

1. Extend the left base extension and left sliding

fence (See “Sliding Fence and Base Extension”

on pages 30 and 31)

Note: Be sure to move left sliding fence away

from the blade to avoid cutting into the fence

when bevel cutting. The left sliding fence may

need to be removed when performing extreme

bevel cuts and most compound cuts (see page

30).

2. With one hand, pull the bevel lock lever forward

to unlock the saw head. (see figure 42)

3. Adjust your left bevel stop to one of the three

pre-set locations 22.5°, 33.9°, 45° and 47° Left, if

desired, tilt head left until you reach the desired

angle on your bevel scale. (see figure 42)

4. Lock the bevel lock by pushing it toward the back

of the saw.

5. Follow procedures for either chop cut or slide cut

(see page 33).

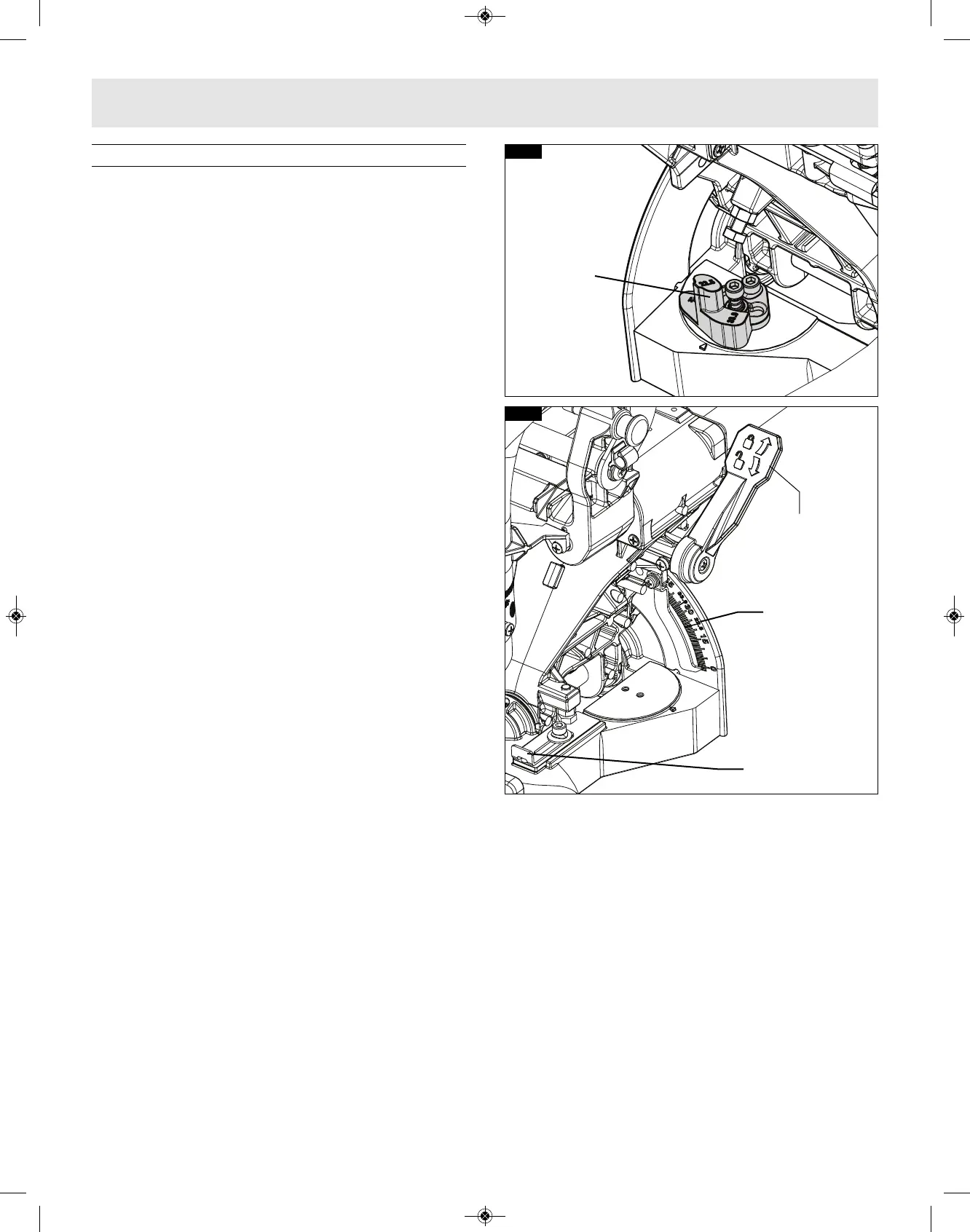

Bevel Scale

-2

° Bevel

Stop

FIG. 42

Bevel Lock

Level

Bevel Stop

Indicator

FIG. 41

Saw Operations

Loading...

Loading...