English–111 609 929 F69 • (04.10) PS

Clamping the Work Piece

(see Figure

)

Before all work on the machine, pull the mains

plug.

To ensure optimum working safety, the work piece

must always be firmly clamped.

Do not work with work pieces that are too small to

clamp.

When clamping the work piece, do not

reach with the fingers under the clamping

lever of the quick action clamp.

Press the work piece firmly against the fence 18 and

the fence extension 19.

Insert the quick action clamp 21 provided into one of

the holes 58 intended for it. Adapt the quick action

clamp to the work piece by twisting the threaded rod

57. Press the clamping lever 56 and thereby firmly

clamp the work piece.

Horizontal Mitre Angle Settings

Before all work on the machine, pull the mains

plug.

To ensure precise cuts, the basic adjustments of the

electro#tool must be checked and adjusted as neces#

sary after intensive use (see Section „Checking and

Adjusting Basic Adjustment“).

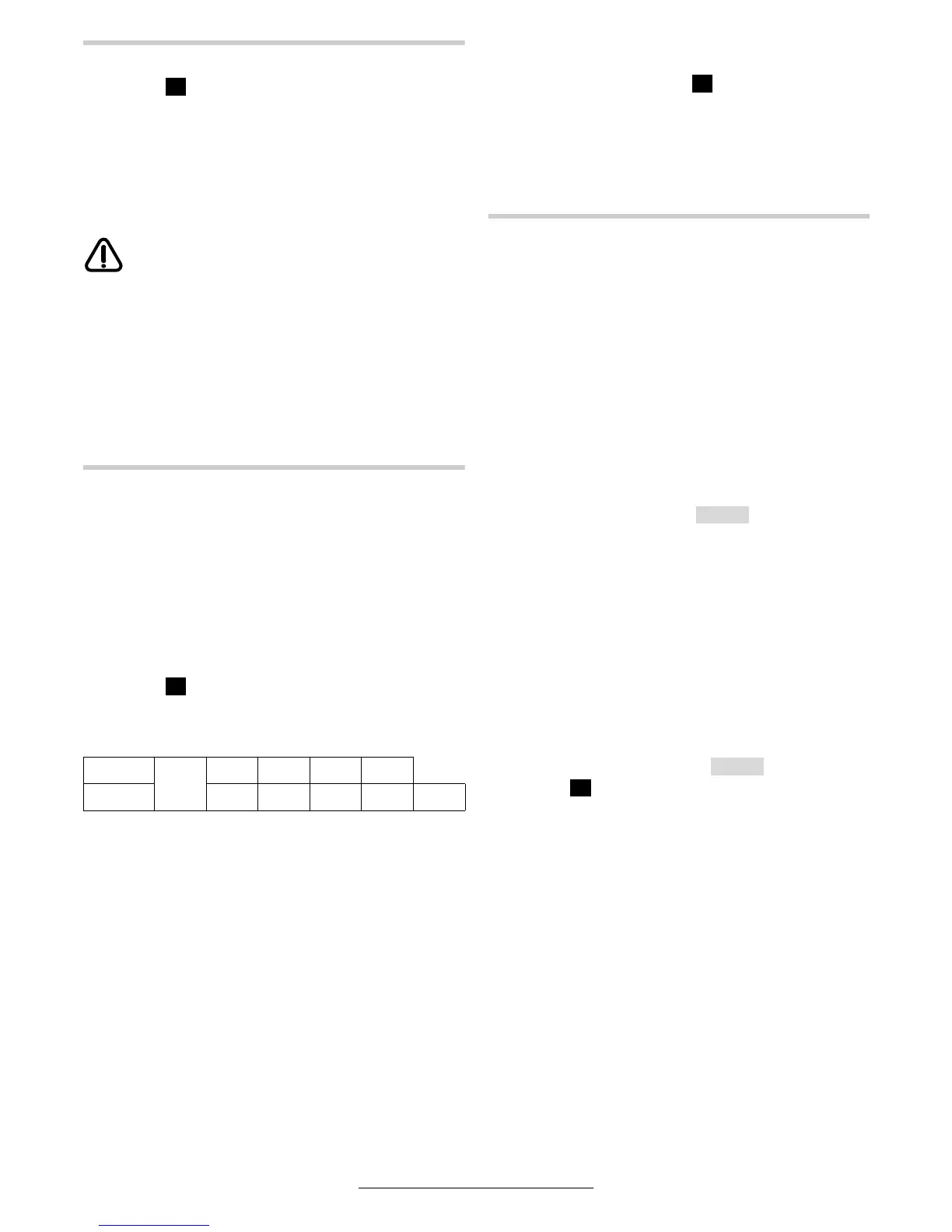

Standard Horizontal Mitre Angles

(see Figure

)

For quick and precise setting of often used mitre an#

gles, detents 15 are provided on the saw table:

:

Place the machine in the working position.

Loosen the locking knob 12 in case it is tightened.

Pull the lever 13 and turn the saw table 16 to the de#

sired mitre angle to the right or the left. Release the le#

ver. The lever must be felt to engage in the detent.

Variable Horizontal Mitre Angle

The horizontal mitre angle can be set in the range from

52° (left side) to 60° (right side).

Place the machine in the working position.

Loosen the locking knob 12 in case it is tightened.

Pull the lever 13 and press the locking clamp 11 at the

same time until it engages in the groove provide for this

purpose (see the illustration

). In this manner, the

saw table becomes freely moveable.

Rotate the saw table 16 to the left or right until the an#

gle indicator 71 points to the desired mitre angle.

Retighten the locking knob 12 .

Vertical Bevel Angle Settings

Before all work on the machine, pull the mains

plug.

To ensure precise cuts, the basic adjustments of the

electro#tool must be checked and adjusted as neces#

sary after intensive use (see Section „Checking and

Adjusting Basic Adjustment“).

The vertical bevel angle can be set in the range from

47° (left side) to 46° (right side).

The standard angles of 0° and 45° are each provided

by factory adjusted end stops. A fixed angle setting for

the angle 33.9° is also possible.

Left Bevel Angle Range

Place the machine in the working position.

Slide the left fence extension 19 completely outward.

Loosen the clamping handle 14.

Swing the tool arm with the handle 5 to the left until the

angle indicator 31 points to the desired bevel angle.

Hold the tool arm in this position and retighten the

clamping handle 14.

The clamping force must securely hold the tool arm in

any vertical bevel angle position.

Right Bevel Angle Range

(see Figure

)

Place the machine in the working position.

Slide the right fence extension 19 completely outward.

Loosen the clamping handle 14.

Tilt the tool arm with the handle 5 out of the 0° position

somewhat to the left and turn the knob 39 until the de#

sired bevel angle range is indicated.

Swing the tool arm with the handle 5 to the right until

the angle indicator 22 points to the desired bevel an#

gle.

Hold the tool arm in this position and retighten the

clamping handle 14.

The clamping force must securely hold the tool arm in

any vertical bevel angle position.

Left

0°

15° 22,5° 31,6° 45°

Right 15° 22,5° 31,6° 45° 60°

I

J

K

45°-0

0-45°

L

Loading...

Loading...