English–121 609 929 F69 • (04.10) PS

Standard 0° Angle

So that the standard 0° angle can be easily set again,

the knob 39 engages in the bevel angle range

when the tool arm is swung from the right over the 0°

position.

Full Bevel Angle Range

Place the machine in the working position.

Slide both fence extensions 19 completely outward.

Loosen the clamping handle 14.

Tilt the tool arm with the handle 5 out of the 0° position

somewhat to the left and turn the knob 39 until the de#

sired bevel angle range is indicated.

Swing the tool arm with the handle 5 to the left or right

until the angle indicator 31 or 22 points to the desired

bevel angle.

Hold the tool arm in this position and retighten the

clamping handle 14.

The clamping force must securely hold the tool arm in

any vertical bevel angle position.

Standard 33.9° Angle

For the standard angle of 33.9°, pull the setting knob

32 completely out and turn by 90°. Then swing the

tool arm with the handle 5 until the tool arm audibly en#

gages.

Adjusting the Handle

(see Figure

)

Before all work on the machine, pull the mains

plug.

The handle 5 can be rotated to four different positions

for comfortable handling of the tool arm while sawing.

For this purpose, open the clamp 3.

Pull the lever 4 to the front and rotate the handle until

it engages in the desired position.

Release the lever 4 and close the clamp 3.

Putting into Operation

Switching On and Off

To put into operation, pull the on/off switch 25 in the

direction of the handle 5.

For safety reasons, the on/off switch of the ma

chine cannot be locked on but must remain de

pressed during operation.

For Sawing, first press the unlocking button 6. (see

Figure )

The locking lever 41 then frees the swinging guard 8

and the tool arm can be guided downward.

To switch off the machine, release the on/off switch

25.

0 601 B22 537 (Australia):

To put into operation, first press the unlocking

button 6. Then press the on/off switch 25 and hold it

depressed.

For safety reasons, the on/off switch of the ma

chine cannot be locked on but must remain de

pressed during operation.

To switch off the machine, release the on/off switch

25.

Working Instructions

Before all work on the machine, pull the mains

plug.

General Sawing Instruction

For all cuts, it must first be ensured that

the saw blade at no time can come in con

tact with the fence, screw clamp or other

machine parts. Remove possible interfer

ing auxiliary stops or adjust them accord

ingly.

Do not load the machine so heavily that it comes to a

standstill.

Advancing that is too fast reduces considerably the

performance capability of the electro#tool and reduces

the service life of the saw blade.

Use only sharp saw blades that are suitable for the ma#

terial being worked.

Hand Positioning

Keep fingers, hands and arms away from the rotating

saw blade.

Do not cross your arms when operating the tool arm

(right#handed persons: see Figure ; left#handed

persons: see Figure ).

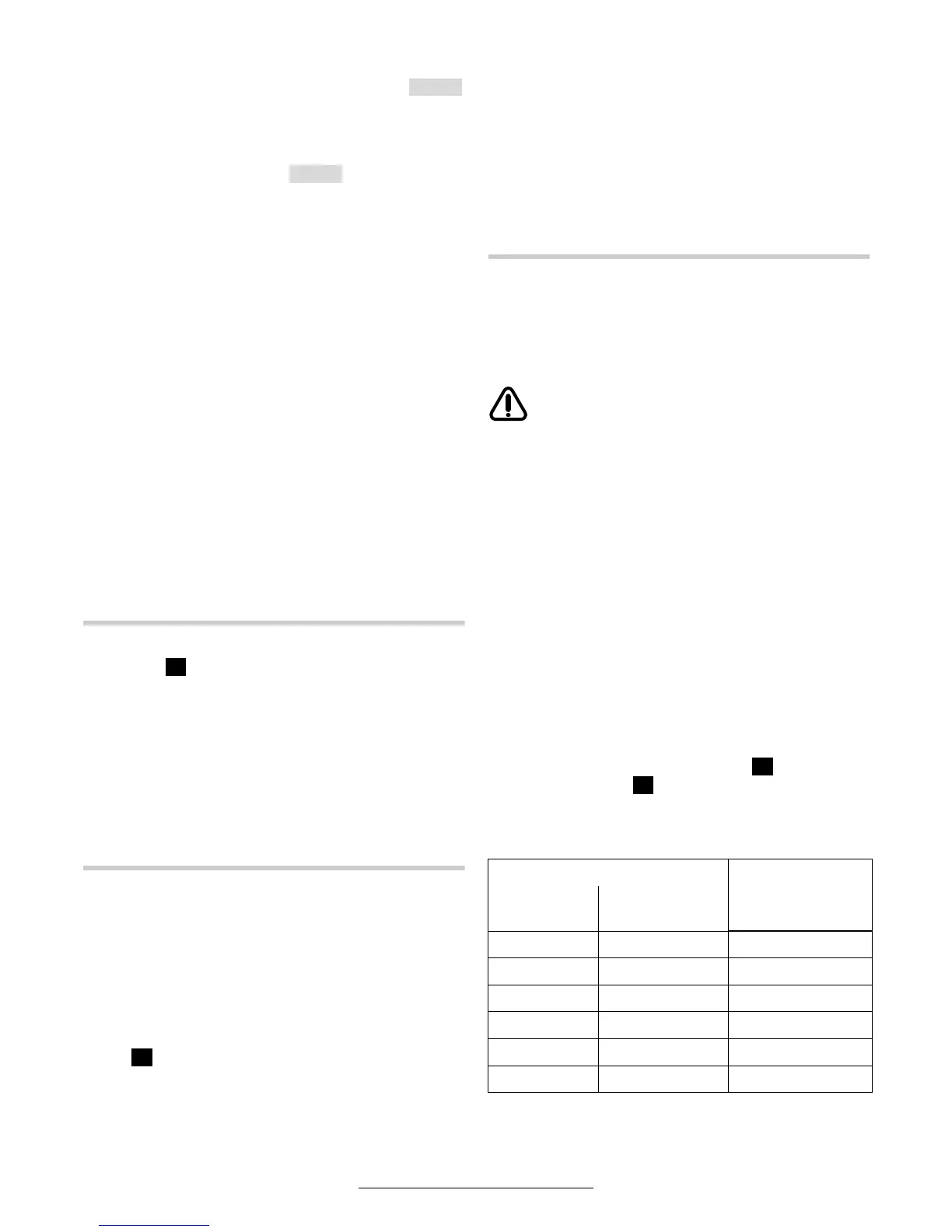

Maximum Work Piece Dimensions

45°-0

45° +

M

N

Mitre Angle Height x Width

[mm]

Mitre

(Horizontal)

Bevel

(Vertical)

0° 0° 85 x 305

45° 0° 85 x 216

0° 45° Left 50 x 305

0° 45° Right 32 x 305

45° 45° Left 50 x 216

45° 45° Right 32 x 216

O

P

Loading...

Loading...