30 | Electrical SM Series Heat Pump

SM Series Heat Pump6 720 220 406 (2013/1) Subject to change without prior notice

Safety Devices and the UPM Controller

Figure # 96

[1] Board power indicator

[2] UPM Board LED indicator

[3] Water coil freeze protection temperature

selection

[4] Air coil freeze protection temperature selection

[5] UPM board settings

[6] Water coil freeze connection

[7] Air coil freeze connection

[8] LCD connection

[9] 24VAC power hot

[10] To compressor contactor

[11] High pressure switch connection

[12] Call for compressor

[13] Low pressure switch connection

[14] 24VAC power common

Each unit is factory provided with a Unit Protection

Module (UPM) that controls the compressor

operation and monitors the safety controls that

protect the unit.

Safety controls include the following:

• High pressure switch located in the refrigerant

discharge line and wired across the HPC

terminals on the UPM

• Low pressure switch located in the unit

refrigerant suction line and wired across

terminals LPC1 and LPC2 on the UPM.

• Water side freeze protection sensor, mounted

close to condensing water coil, monitors

refrigerant temperature between condensing

water coil and thermal expansion valve. If

temperature drops below or remains at freeze

limit trip for 30 seconds, the controller will

shut down the compressor and enter into a

soft lockout condition. The default freeze limit

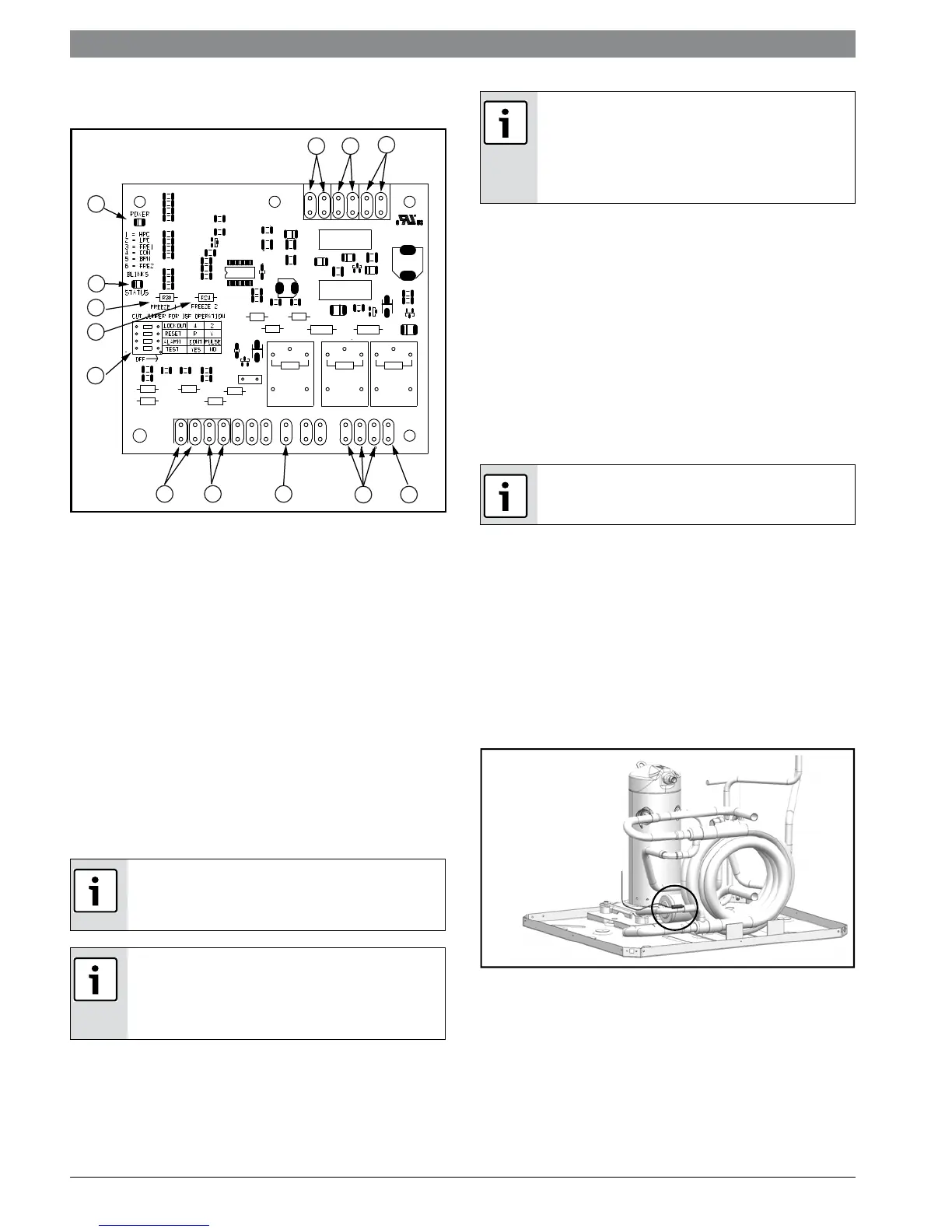

trip is 30°F, however this can be changed to

15°F by cutting the R30 or Freeze1 resistor

located on top of DIP switch SW1. (Figure #97)

Figure # 97

If the unit is being connected to a thermostat

with a malfunction light, this connection is made

at the unit malfunction output or relay.

If the thermostat is provided with a malfunction

light powered off of the common (C) side of the

transformer, a jumper between “R” and “COM”

terminal of “ALR” contacts must be made.

1

2

3

4

5

6

78

9

10

11

1213

If the thermostat is provided with a malfunction

light powered off of the hot (R) side of the

transformer, then the thermostat malfunction

light connection should be connected directly to

the (ALR) contact on the unit’s UPM board.

UPM Board Dry Contacts are Normally Open

(NO)

Loading...

Loading...