Electrical | 33SM Series Heat Pump

6 720 220 406 (2013/1)SM Series Heat Pump

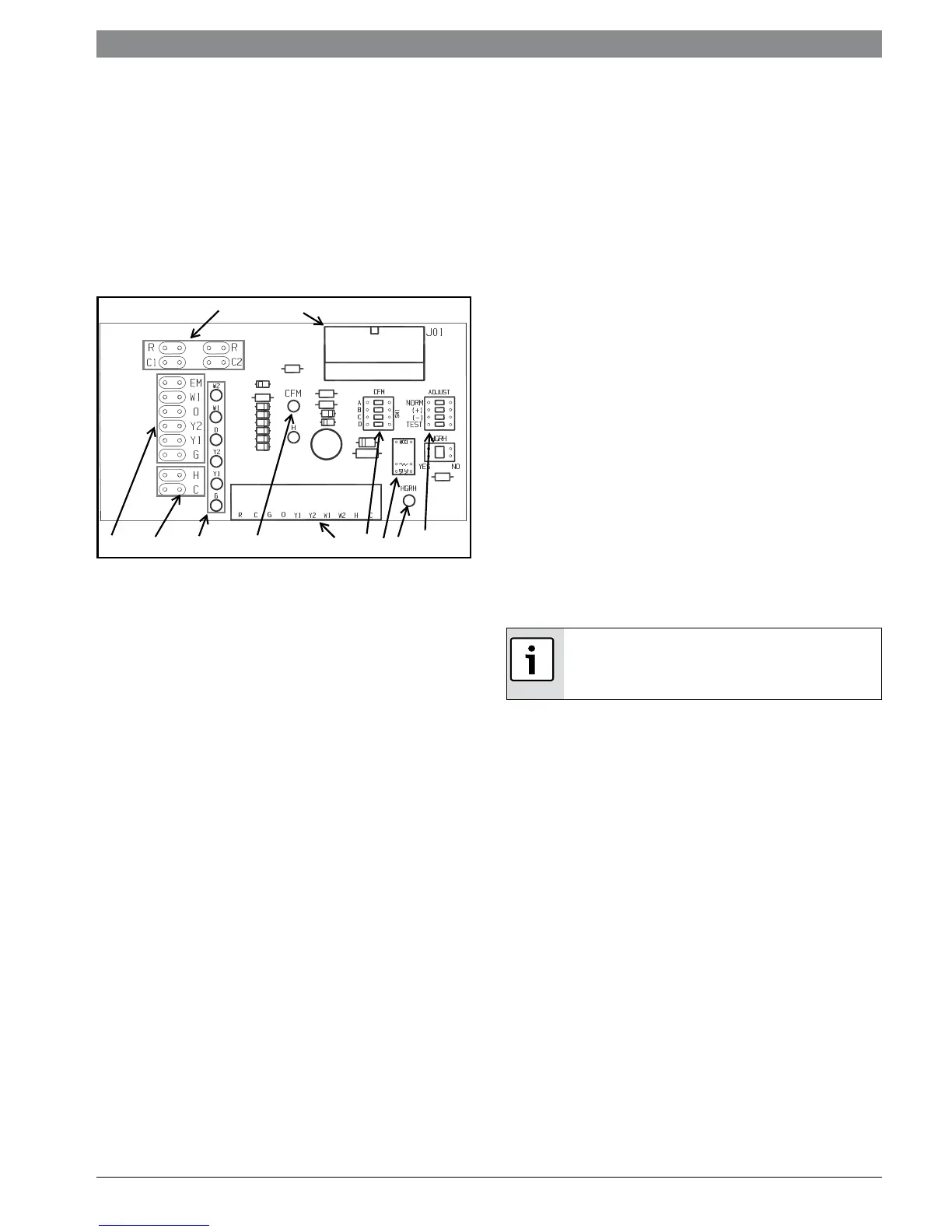

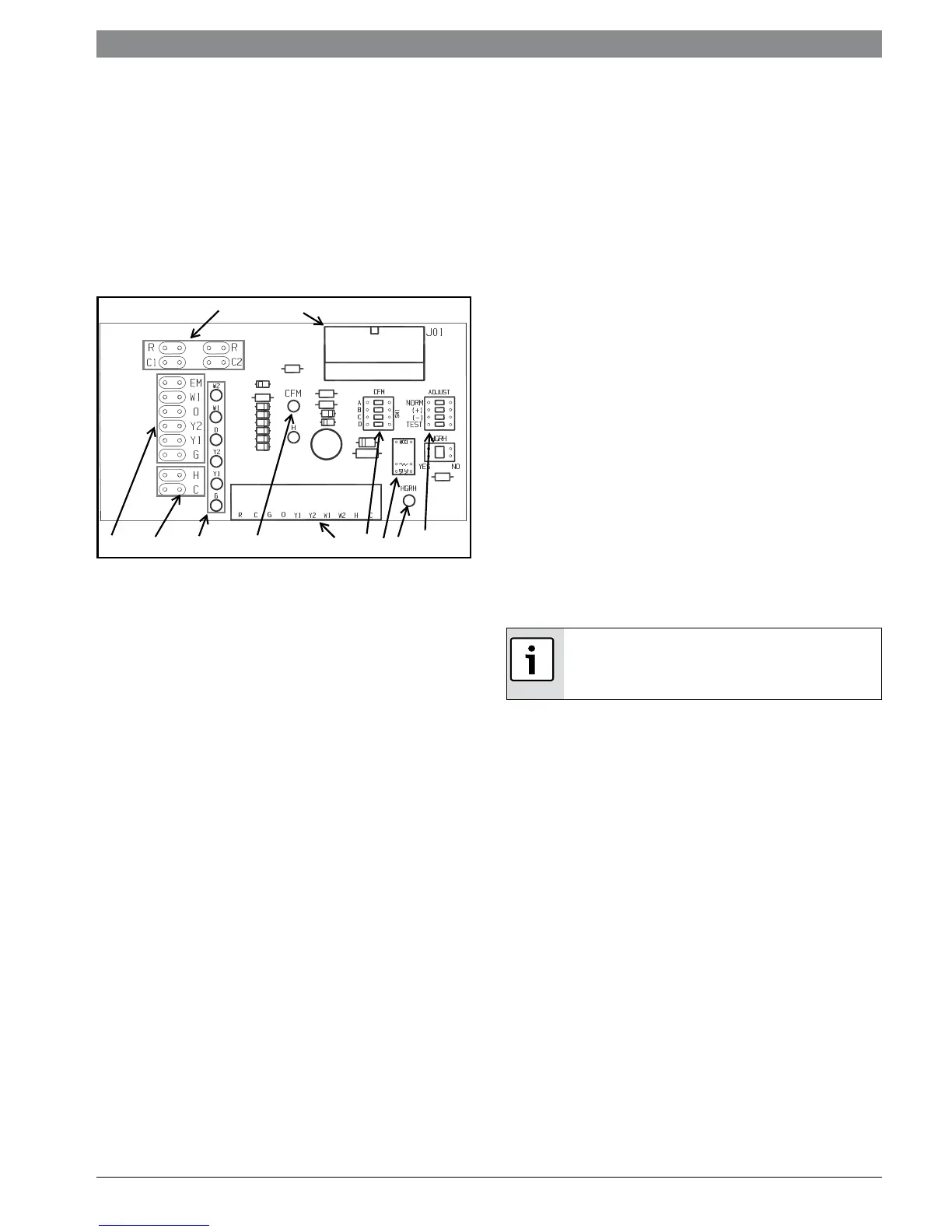

ECM INTERFACE BOARD

Thermostat wiring is connected to the 10 pin

screw type terminal block on the lower center

portion of the ECM Interface Board. In addition to

providing a connecting point for thermostat wiring,

the interface board also translates thermostat

inputs into control commands for the Electronic

Commutated Motor (ECM) DC fan motor and

displays an LED indication of operating status. The

thermostat connections and their functions are as

follows:

Figure # 100

[1] Motor harness plug

[2] Blower CFM adjustment

[3] Motor settings

[4] Dehumidification indication

[5] Thermostat digital inputs

[6] CFM count indicator

[7] Thermostat input status indication

[8] Reheat digital outputs

[9] Thermostat outputs

[10] 24 VAC

Just above the connector block is a single red LED

labeled CFM that will blink intermittently when the

unit is running and may flicker when the unit is off.

This LED indicates the air delivery of the blower at

any given time. Each blink of the LED represent

approximately 100 CFM of air delivery so if the LED

blinks 12 times, pauses, blinks 12 times, etc. the

blower is delivering approximately 1200 CFM.

To the right of the thermostat connection block is

a green LED labeled dehumidify. Just above and to

the right of the thermostat connection block are

two banks of DIP switches labeled ADJ and CFM.

The ADJ bank DIP switches are labeled NORM, (+),

(-), Test and HGHR position from the factory,

however, airflow can be increased (+) or

decreased (-) by 15% from the pre-programmed

setting by relocating the DIP switch in this section.

The TEST position is used to verify proper motor

operation. If a motor problem is suspected, move

the ADJ DIP switch to the TEST position and

energize G on the thermostat connection block. If

the motor ramps up to 100% power, then the

motor itself is functioning normally. Always

remember to replace the DIP switch to NORM, (+)

or (-) after testing and reset the unit thermostat to

restore normal operation.

HGRH switch is used to select operating mode

between units equipped with:

1. Re-heat coils

2. Cool to dehumidify

10

1

27

8

9

5

3

46

Y1 First Stage Compressor Operation

Y2 Second Stage Compressor Operation

G Fan

O Reversing Valve (energized in cooling)

W1 Auxiliary Electric Heat (runs in

conjunction with compressor)

EM/W2 Emergency Heat (electric heat only)

NC Transformer 24 VAC Common (extra

connection)

C1 Transformer 24 VAC Common

(primary connection)

R Transformer 24 VAC Hot

H Dehumidification Mode

CFM LED indication is an approximation. Utilize

conventional Test and Balance equipment for

accurate airflow measurement.

Loading...

Loading...