18

be removed or installed by sliding on or off ar-

bor shaft 6 (Fig. 18).

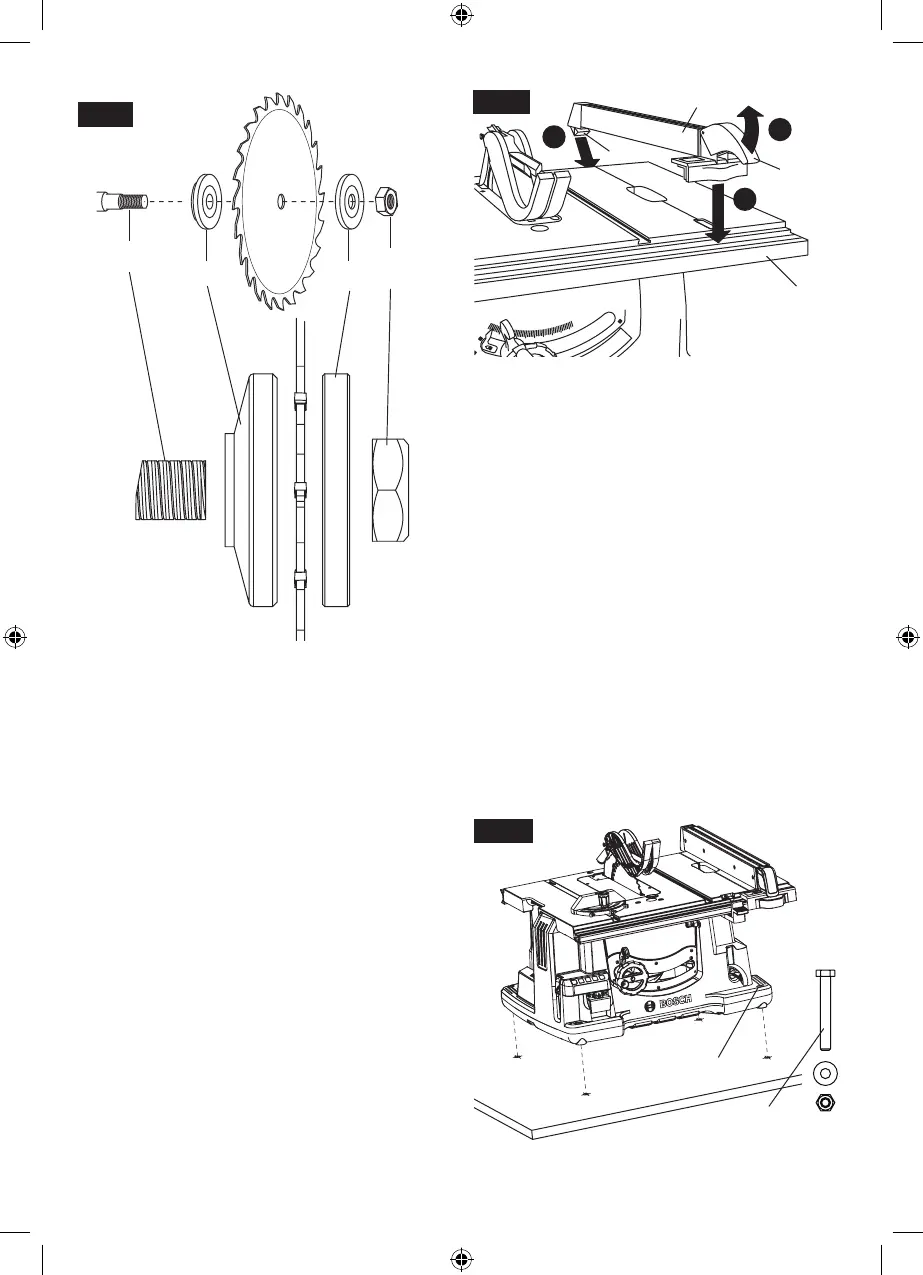

3. Assemble inner washer 7 and new blade as

shown in figure 18, making certain the TEETH

OF THE BLADE ARE POINTING DOWN AT

THE FRONT OF THE TABLE. NOTE: The

printing on different saw blades is not always

on the same side.

4. Assemble outer washer 5 and arbor nut 3 as

shown in figure 17. While holding arbor lock le-

ver 2 securely, tighten arbor nut 3 clockwise

with the wrench 4. (Fig. 16).

5. Position table insert 21 in pocket of table so

tabs 21a on table insert 21 are in slots in pock-

et of table and push down and secure in place

using table insert lock 22 (Fig.4, page 13).

ATTACHING RIP FENCE

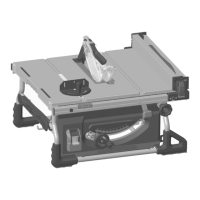

1. Raise rip fence handle 1, so holding clamp 2 is

out far enough to fit on the table 3 and into “V”

groove located on the back of rear rail (Fig. 19).

2. Position the rip fence 4 over table 3 holding up

the front end, first engage holding clamp 2 with

rear rail.

3. Lower front end onto front rail 5.

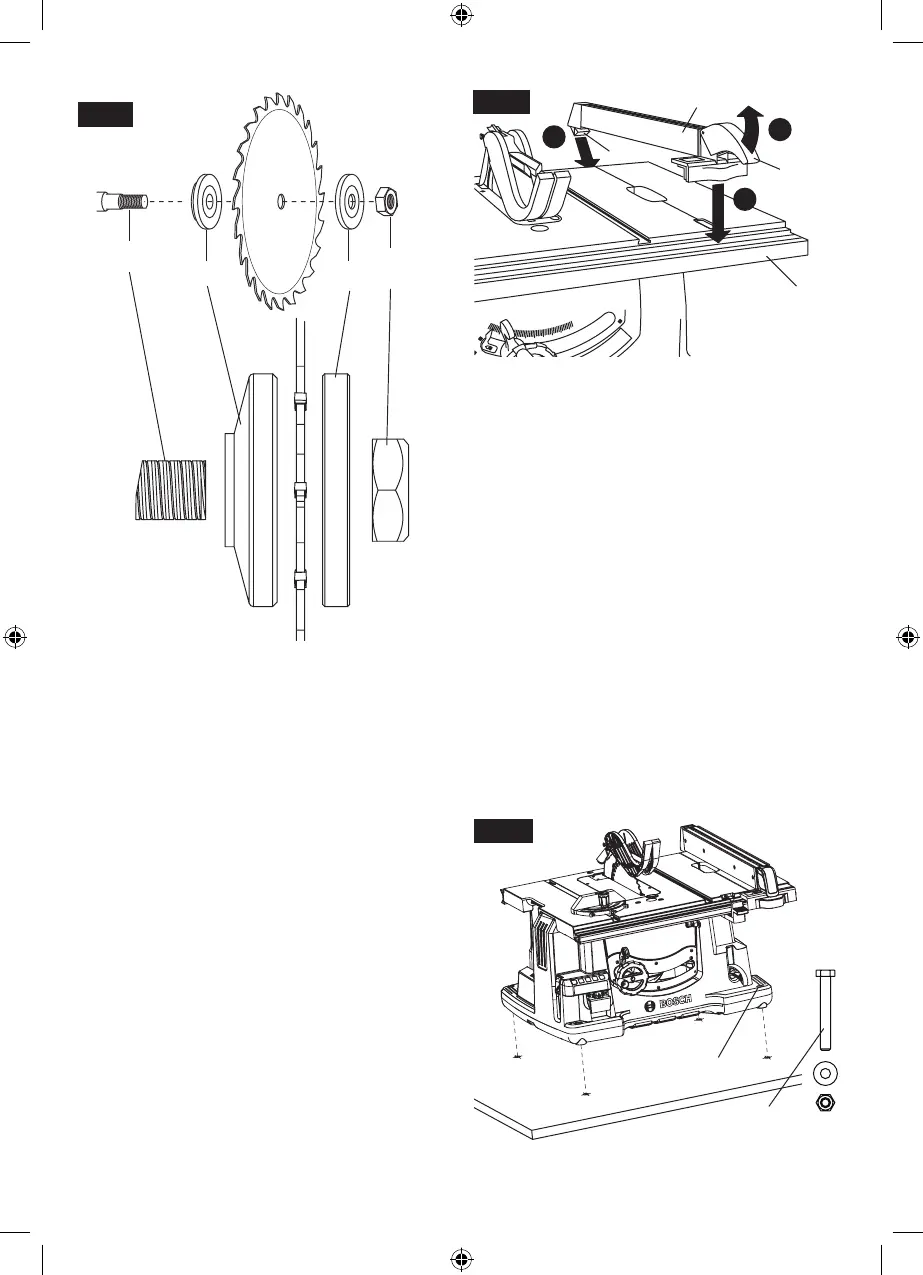

MOUNTING THE TABLE SAW

If table saw is to be used in a permanent location,

it should be fastened securely to a firm support-

ing surface such as a stand or workbench, using

the four mounting holes 6 (Fig. 19).

1. If mounting to a workbench, the base should

be bolted securely using 5/16” hex bolts (not

included) through mounting holes 6.

Hint: If workbench is 3/4” thick, bolts will have

to be at least 3-1/2” long - if workbench is 1-1/2”

thick, bolts should be at least 4-1/2” long.

2. Locate and mark where the saw is to be mount-

ed, relative to holes in the base of the tool.

3. Drill four (4) 3/8” diameter holes through work-

bench.

4. Place table saw on workbench aligning holes

in base with holes drilled in workbench.

5. Insert four (4) 5/16” dia. bolts through holes in

base and supporting surface; then secure with

(4) 5/16” flat washers and (4) 5/16” hex nuts.

3

5

7

6

Fig. 18

B

C

A

Fig. 19

1

5

3

2

4

6

5/16” HEX BOLT,

WASHER &

HEX NUT (X4)

Fig. 20

1600A009XC 09-15.indb 18 9/14/15 1:51 PM

Loading...

Loading...