Do you have a question about the Bosch GTS1031 and is the answer not in the manual?

Covers work area, personal safety, and general warnings for tool operation.

Focuses on feed direction, tool care, and kickback prevention measures.

Details eye/body protection, tool maintenance, and accessory use precautions.

Guidelines for selecting and using appropriate extension cords for safety.

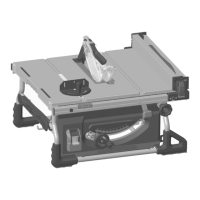

Details on major parts like the power switch, blade controls, and rip fence.

Information on storage locations and system components like dust ports.

Lists all included components for verification against the manual.

Step-by-step guide to set up the riving knife for operation.

Instructions for mounting the main blade guard assembly.

Procedure for installing the anti-kickback mechanism onto the riving knife.

Specifications and warnings for selecting appropriate replacement blades.

Handling and safety precautions for carbide blades during installation and use.

Instructions for securely attaching the saw to a workbench or stand.

Setting precise 0 and 45-degree angles for blade tilt.

Ensuring blade alignment with table slots for accurate cuts.

Aligning rip fence and calibrating fence pointer for accurate measurements.

Aligning riving knife with blade and table pointer with fence pointer.

Setting the height of the table insert for proper flush fit.

Operating the power switch and understanding guard components.

How to properly store Smart Guard components when not in use.

How to extend the table for wider workpieces.

Guidance on using scales for accurate rip cuts with extended table.

Making and using push sticks, blocks, and auxiliary fences for safety.

Guide for crafting a featherboard for workpiece support.

Attaching an auxiliary facing to the miter gauge for improved support.

Performing angled cuts using the miter gauge.

Crosscutting with the blade tilted at an angle to the workpiece.

Combining miter and bevel angles for complex cuts.

Using an auxiliary facing with the rip fence for specific cuts.

Performing rip cuts with the blade tilted at an angle.

Making cuts that do not go all the way through the material.

Procedures for installing and using dado blade sets safely.

Reverting the saw to standard configuration after dado operations.

Warnings against cutting metals and masonry materials with the saw.

How to clear dust and perform general upkeep and cleaning.

Identifying lubrication points and listing recommended accessories.

Solutions for power, starting, and blade speed problems.

Diagnosing and fixing common operational faults like vibration and inaccurate cuts.

Addressing issues with handle/wheel movement and making necessary adjustments.

| No Load RPM | 5, 000 RPM |

|---|---|

| Weight | 52 lbs |

| Power Input | 120V |

| Riving Knife | Yes |

| Dust Extraction Port | Yes |

| Amperage | 15 Amps |

| Blade Diameter | 10 inches |

| Arbor Size | 5/8 inches |

| Max Depth of Cut at 90° | 3-1/8 inches |

| Max Depth of Cut at 45° | 2-1/4 inches |

| Max Rip Capacity Right | 18 inches |

| Table Dimensions | 22.5 inches x 20 inches |

| Blade Tilt | 0° - 47° |

Loading...

Loading...