Pack201 | Operator Instructions | Section 3

EN | 2

© Bosch Packaging Technology, Inc.

All rights reserved 2012

3 Operator Instructions

3.1 Start of Production

Preparation

1� Check that there is enough sealing material and

double-sided tape (for the splicer option) on hand

for the day’s production�

2� Have scissors on hand to prepare the sealing

material�

3. Check that all protective covers are in place.

Close all moving covers and doors.

4. Put all guides in place and adjust them to suit the

packaging format.

5. Follow the settings list to set the correct format/

change parts, such as former, side guides, crimp-

er unit and so on, for the product being packaged.

6. Switch on the compressed air.

7. Release the emergency stop(s).

Install Sealing Material

1� Turn ON the main disconnect to apply power to

the control circuits�

2� Push the Emergency Stop button�

3� Remove the outside chuck from the lm spindle.

4� Place a roll of lm on the spindle and replace the

outside chuck� Turn to secure the chuck against

the lm roll.

5� Adjust the centering cone on the lm spindle as

needed�

6� Use the centering knob to nd tune the lm roll

position�

7� If necessary, reposition the inclination arm and/or

roller for proper lm ow.

WARNING

The rolls of sealing material can be heavy

and awkward to handle� Use some type of

lifting device to prevent a possible injury�

8� Move the balance arm until it locks in the down

position�

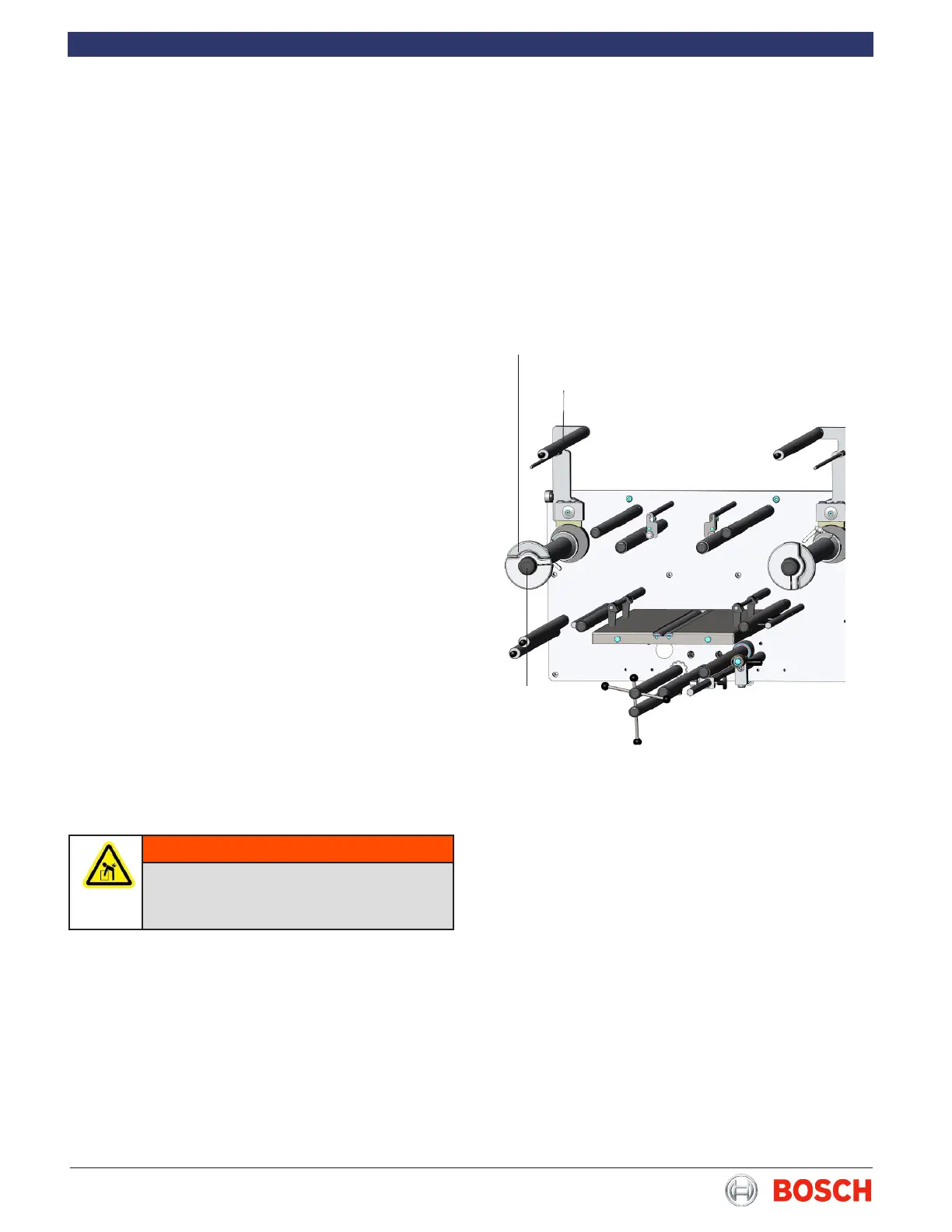

9� Thread the lm through the backstand rollers as

shown on the threading diagram�

10� Pull out the release rod to release the balance

arm�

11� Pull the lm through the former/folding box; bring

the two bottom edges together and draw them

through the rst set of nwheels.

12� Use the Finwheel Open/Close switch to close the

nwheels with the material between them.

Chuck

Centering Knob

Balance Arm

Loading...

Loading...