Pack201 | Operator Instructions | Section 3

EN | 10

© Bosch Packaging Technology, Inc.

All rights reserved 2012

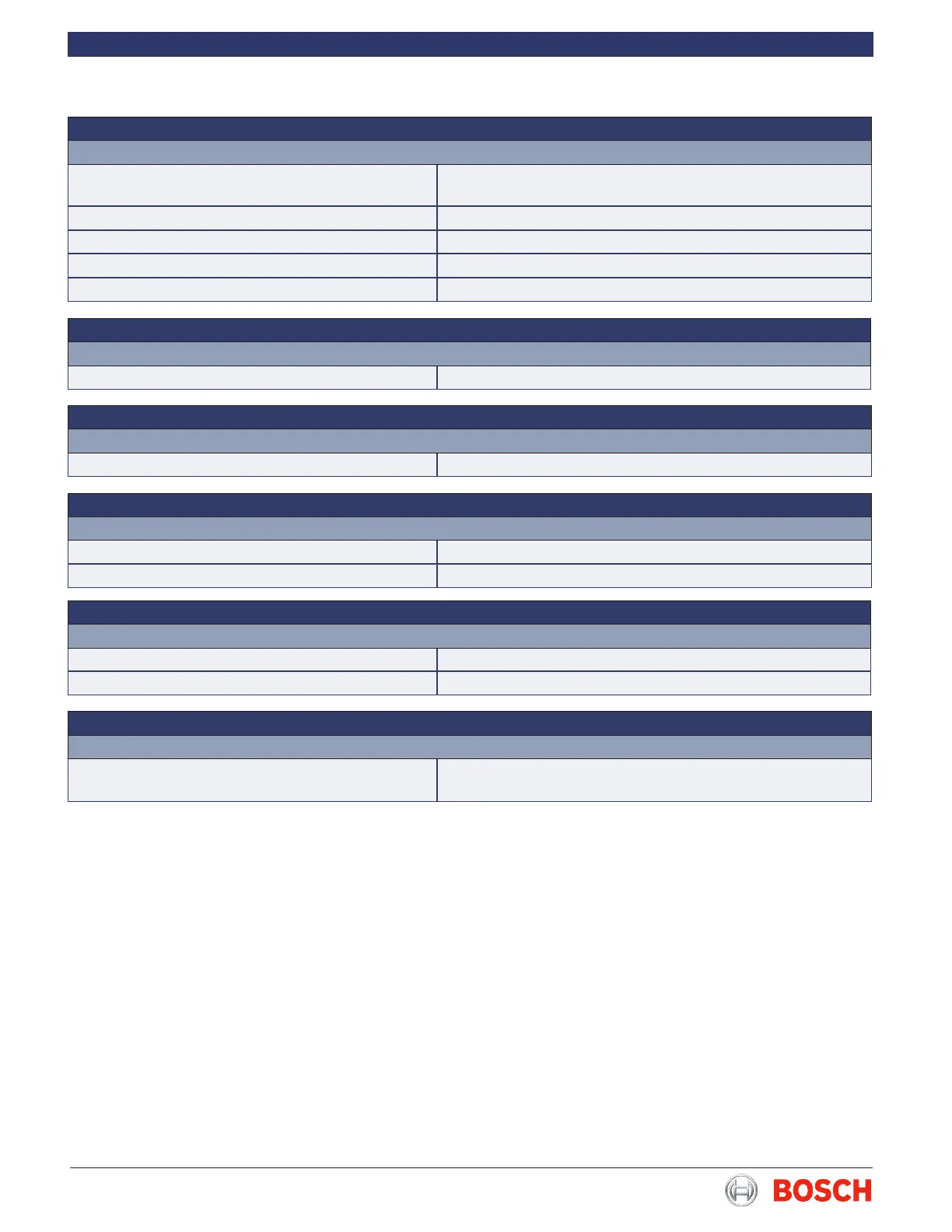

Problem: Sealing material is coming out of the former

Possible Cause Solution

Sealing material is not centered� Turn the adjustment knobs on the ends of the lm spindles to

move the rolls in or out a small amount�

Inclination roller not positioned properly� Adjust the height and angle of the inclination arm and roller�

Incorrect lm width Determine correct lm width.

Former not centered on the infeed centerline Reposition the former�

Incorrect Former size Change former - each product should have its own former�

Problem: The nseal is too deep.

Possible Cause Solution

The lm is too wide Load a narrower lm roll.

Problem: The nseal is twisted.

Possible Cause Solution

The lm is too wide Load a narrower lm roll.

Problem: The blouse of the package is too loose.

Possible Cause Solution

The pivot arm is too high Lower the pivot arm�

The rst nwheel cant adjustment is wrong Adjust the rst nwheel cant.

Problem: The blouse of the package is too tight.

Possible Cause Solution

The pivot arm is too low Raise the pivot arm�

The rst nwheel cant adjustment is wrong Adjust the rst nwheel cant.

Problem: The lm centering knob will not turn clockwise.

Possible Cause Solution

The rear cone is too close to the chuck� Move the rear cone closer to the backstand and reposition

the lm roll.

Loading...

Loading...