Pack201 | Operator Instructions | Section 3

EN | 9

© Bosch Packaging Technology, Inc.

All rights reserved 2012

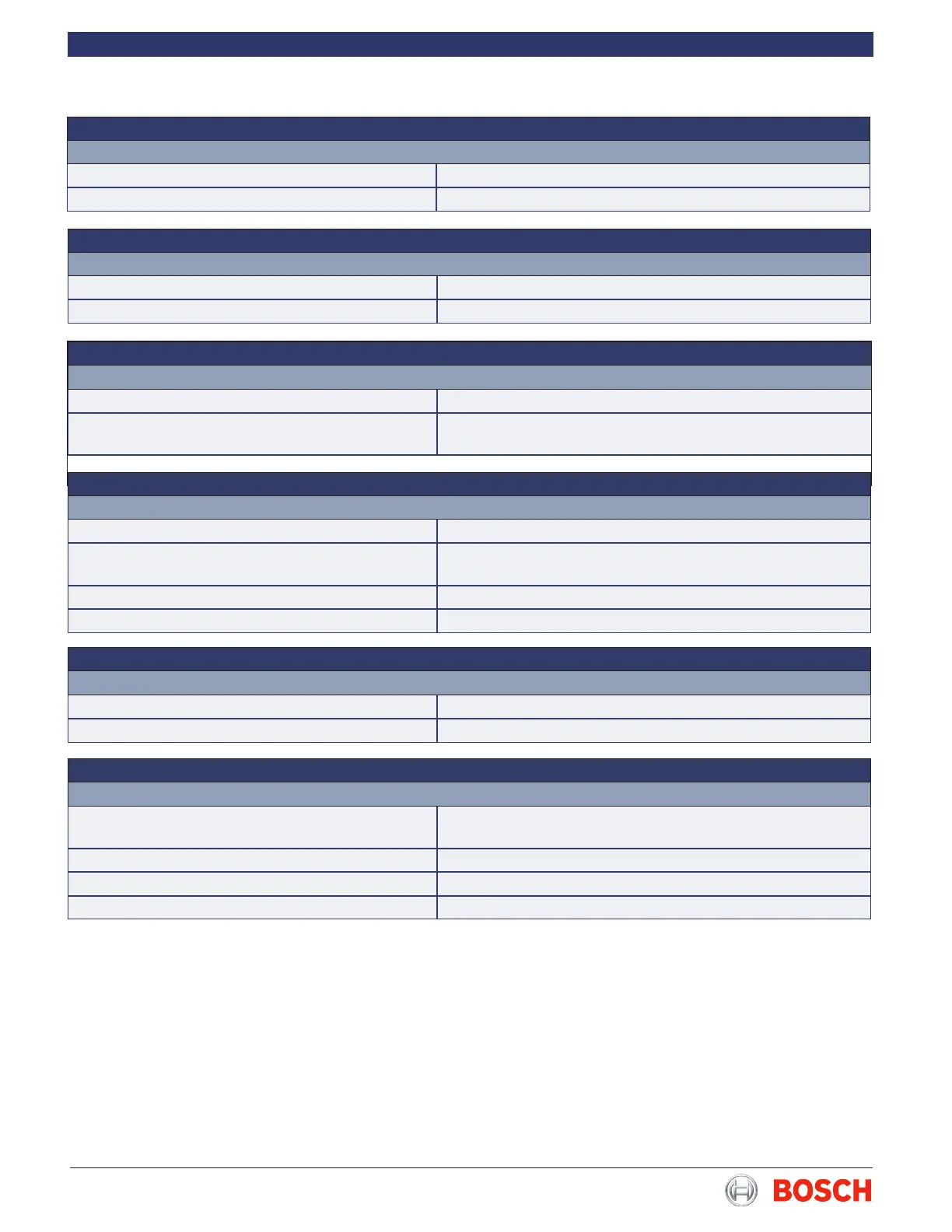

Problem: The endseals are bubbly and/or melted.

Possible Cause Solution

The crimper temperature setting is too high Lower the crimper temperature setting�

The crimpers are dirty Clean the crimpers�

Problem: The lm is blurred or discolored at the edge of the nseal.

Possible Cause Solution

The nwheel temperature setting is too high Lower the nwheel temperature setting.

The nwheels are dirty Clean the nwheels.

Problem: The lm is blurred or discolored at the edge of the endseals.

Possible Cause Solution

The crimper temperature setting is too high Lower the crimper temperature setting�

The crimpers are dirty Clean the crimpers� Refer to the Cleaning the Wrapper chap-

ter in this manual�

Problem: There are ‘chicken tracks’ in the nseal.

Possible Cause Solution

The nwheels are dirty Clean the nwheels.

The balance arm brake is not releasing properly Check that the balance arm brake is releasing properly� If not

releasing properly, call Bosch for further assistance�

The nwheel caps are worn Call Bosch to order new nwheel caps.

The parent roll is bad Call Bosch to order a new parent roll�

Problem: The lm comes out from between the nwheels.

Possible Cause Solution

The nwheels are open Move the nwheel switch to the closed position.

The lm is too narrow Load a wider lm roll.

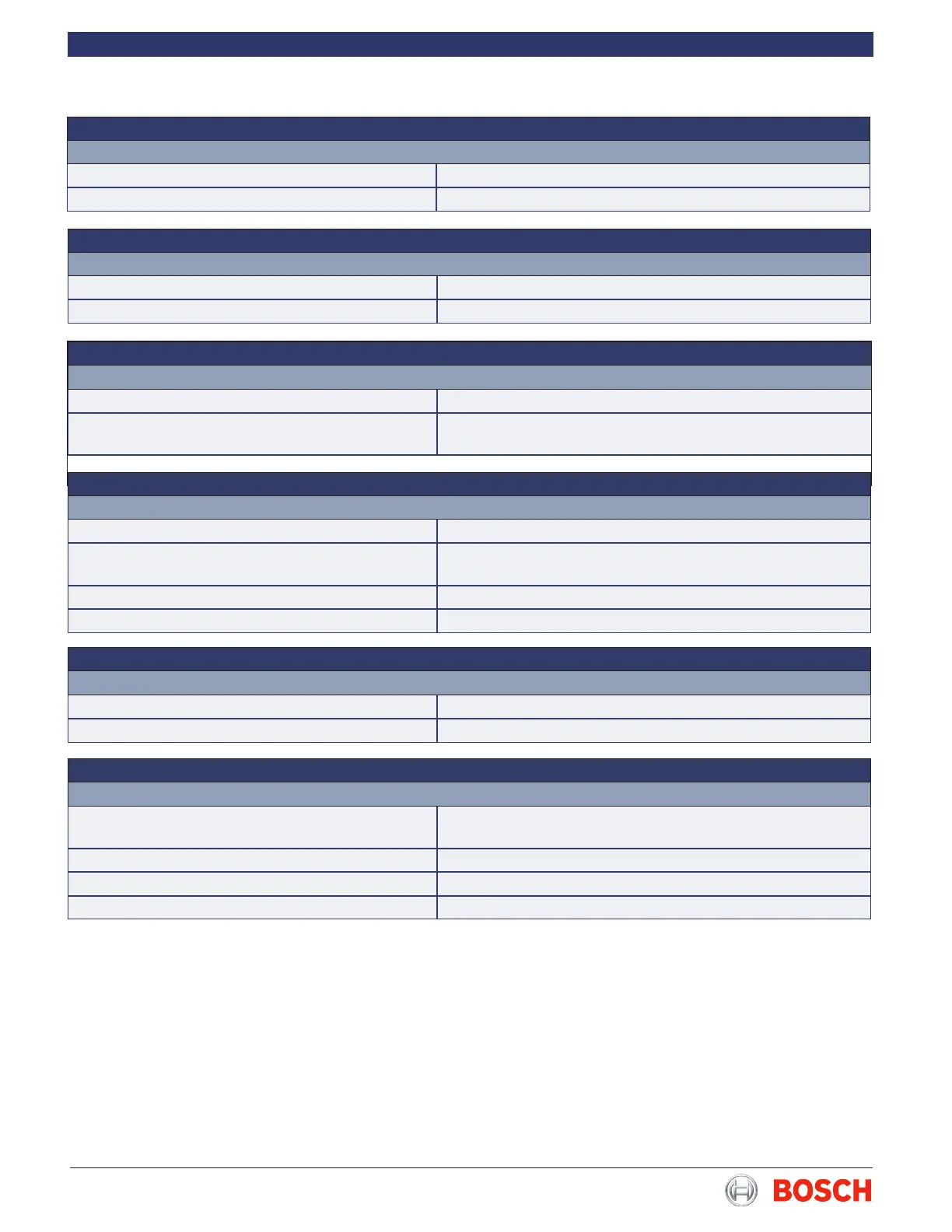

Problem: Sealing material is breaking in the backstand.

Possible Cause Solution

Sealing material not threaded properly through the

rollers�

Check the threading diagram and rethread correctly�

Poor sealing material� Check the material for slight cracks and replace as necessary�

Brake not adjusted/working properly� Check brake function and adjustment�

Power feed roll is not operating properly� Check the power feed roll�

Loading...

Loading...