Pack201 | Operator Instructions | Section 3

EN | 8

© Bosch Packaging Technology, Inc.

All rights reserved 2012

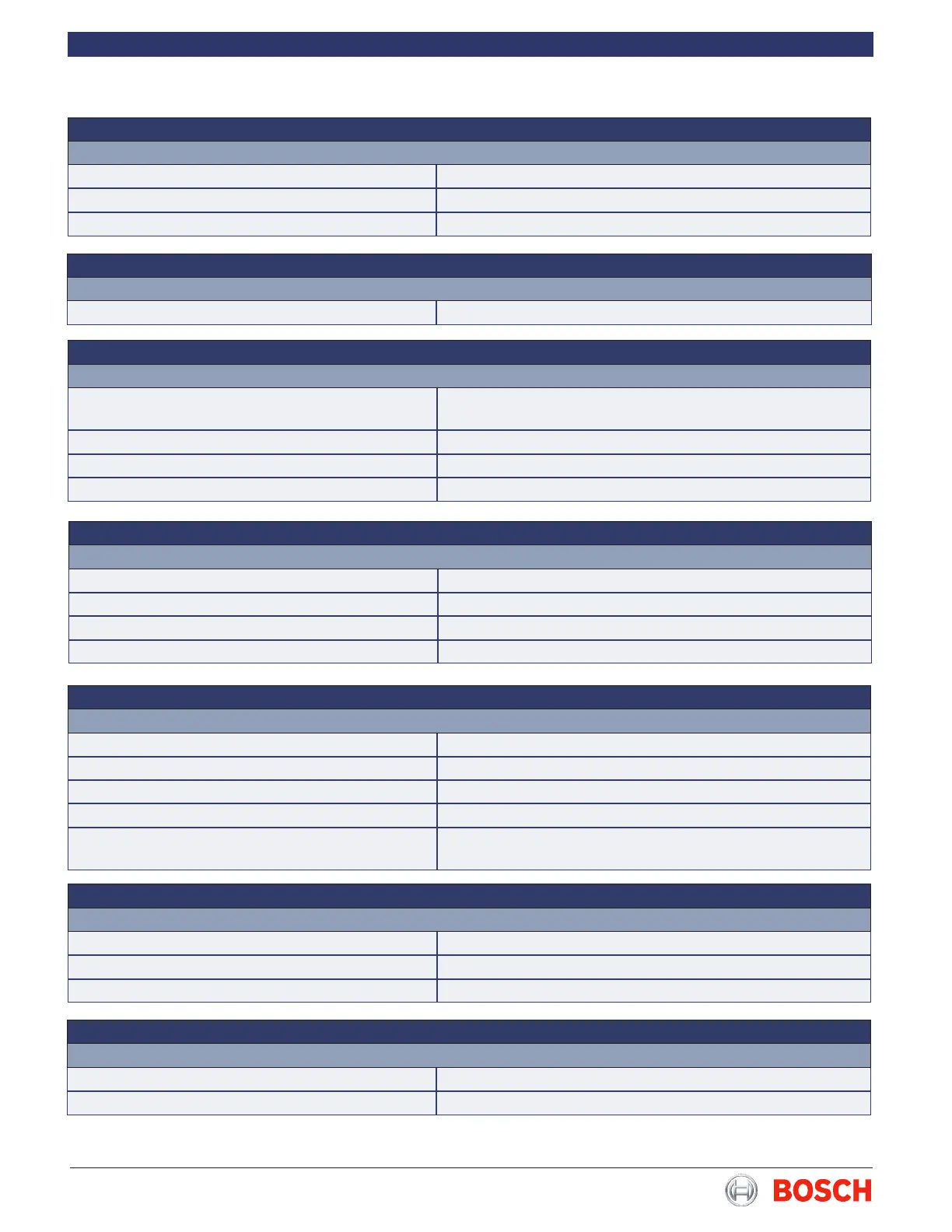

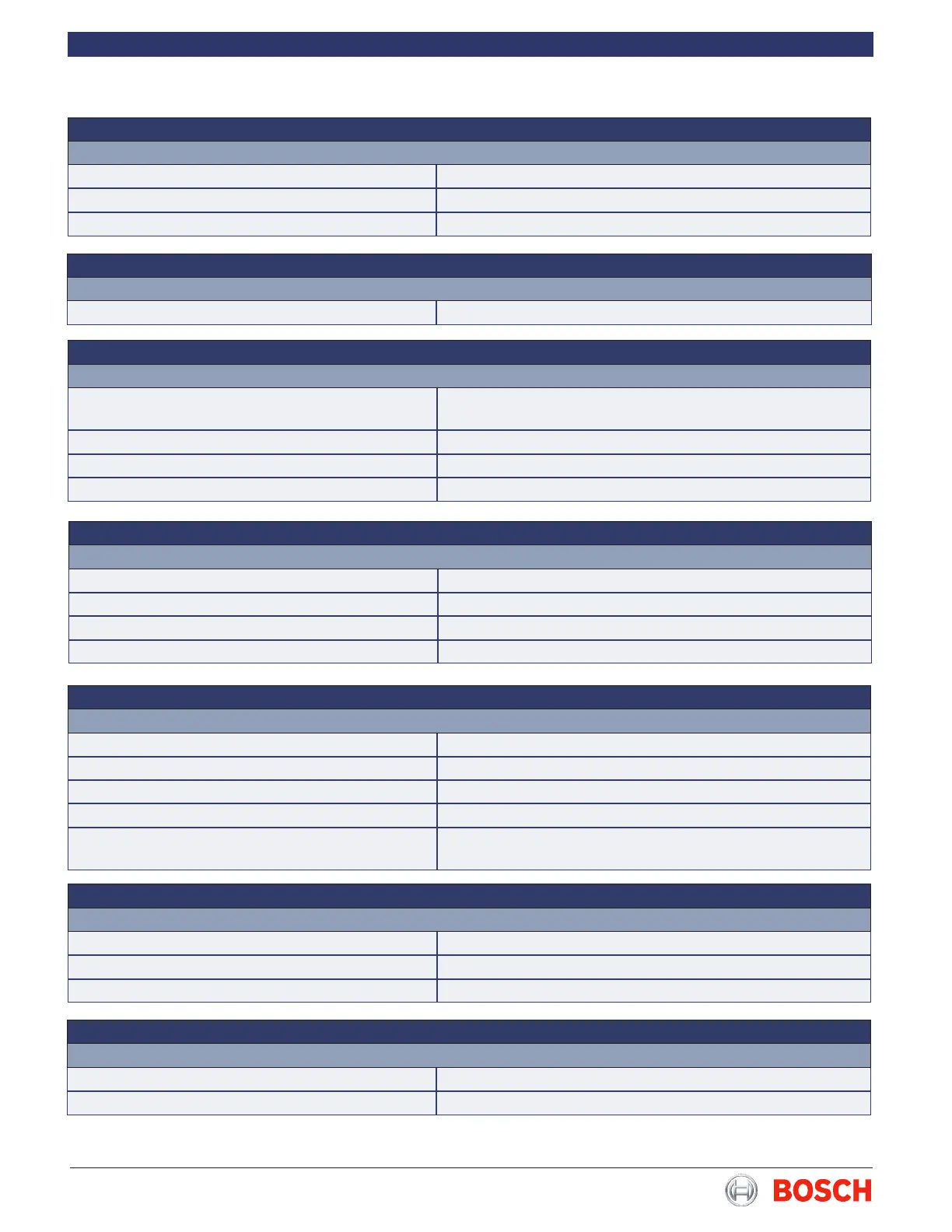

Problem: The lm does not feed properly.

Possible Cause Solution

The lm is not threaded correctly Check the lm threading.

The Finwheels are open Move the nwheel switch to the closed position.

The Finwheels not pressed together tight enough Decrease the gap between the nwheels.

Problem: The serrations on the nwheels are cutting through the lm.

Possible Cause Solution

The nwheels are pressed together too tight Increase the gap between the nwheels.

Problem: The serrations on the crimpers are cutting through the lm.

Possible Cause Solution

There is not enough clearance between the crimp-

ers

Increase the clearance between the crimpers�

The crimper sealing pressure is too high Decrease the crimper sealing pressure�

The endseal temperature is set too high Decrease the endsel temperature setting

The endseal crimpers are not properly aligned Refer to endseal section

Problem: The nseal is not holding together.

Possible Cause Solution

The nwheel temperature setting is too low Increase the nwheel temperature setting.

The nwheels are not pressed together tight enough Decrease the gap between the nwheels.

The lm is too narrow Load a wider lm roll.

A nseal wheel is open Make sure all nwheels are closed.

Problem: The endseals are not holding together.

Possible Cause Solution

The crimper temperature setting is too low Increase the crimper temperature setting�

The crimpers are dirty Clean the crimpers�

There is too much clearance between the crimpers Decrease the clearance between the crimpers�

The crimper sealing pressure is too low Increase the crimper sealing pressure�

Temperature controller fails to hold consistent

temperature

Have qualied electrician check the temperature controller

Problem: The lm is being wrinkled.

Possible Cause Solution

The wrong product spacer has been installed Install the correct product spacer�

The lm tension is not adjusted properly Adjust the balance arm spring tension�

The lm is not centered over the former Center the lm roll on the parent roll.

Problem: The nseals are bubbly and/or melted.

Possible Cause Solution

The nwheel temperature setting is too high Lower the nwheel temperature setting.

The nwheels are dirty Clean the nwheels.

Loading...

Loading...