Pack201 | Operator Instructions | Section 3

EN | 7

© Bosch Packaging Technology, Inc.

All rights reserved 2012

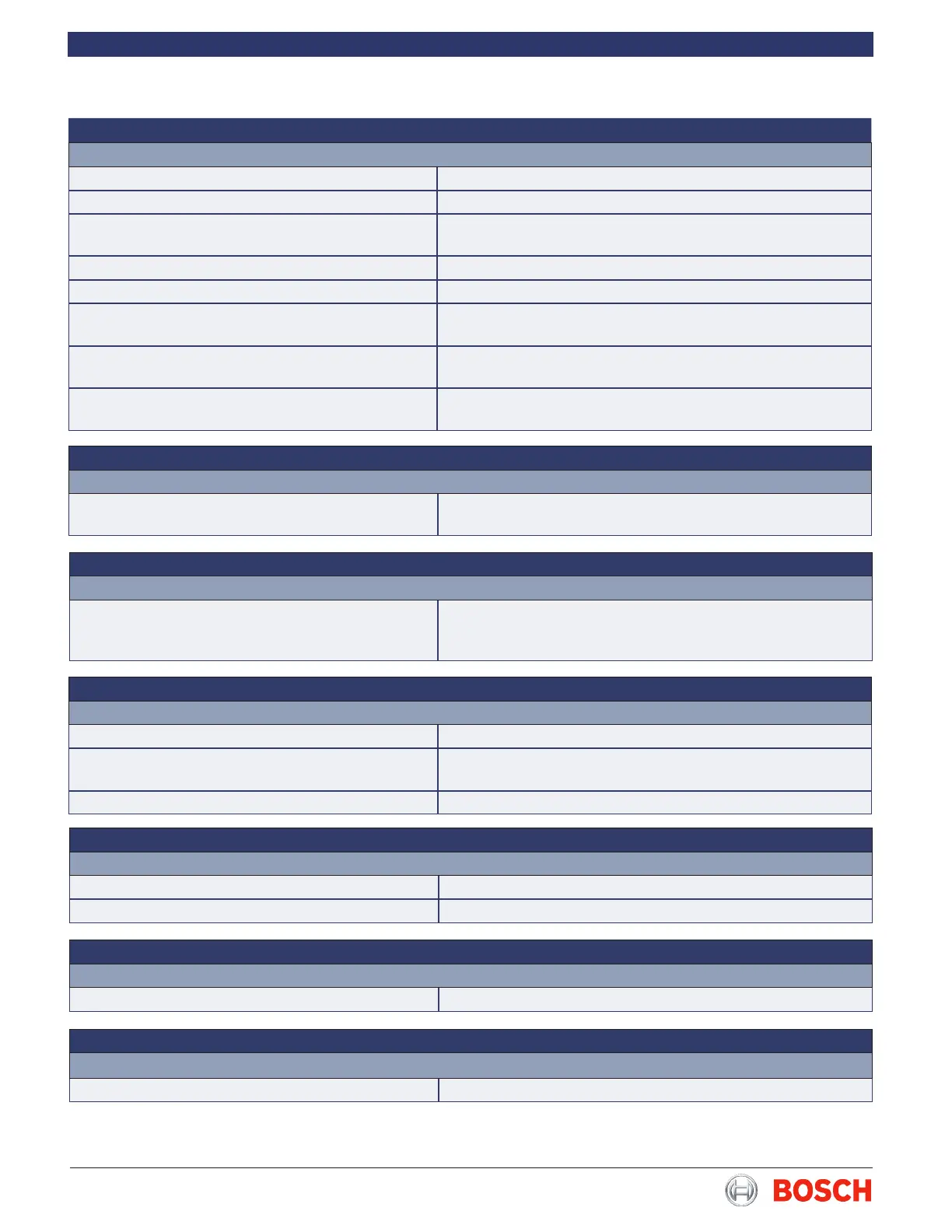

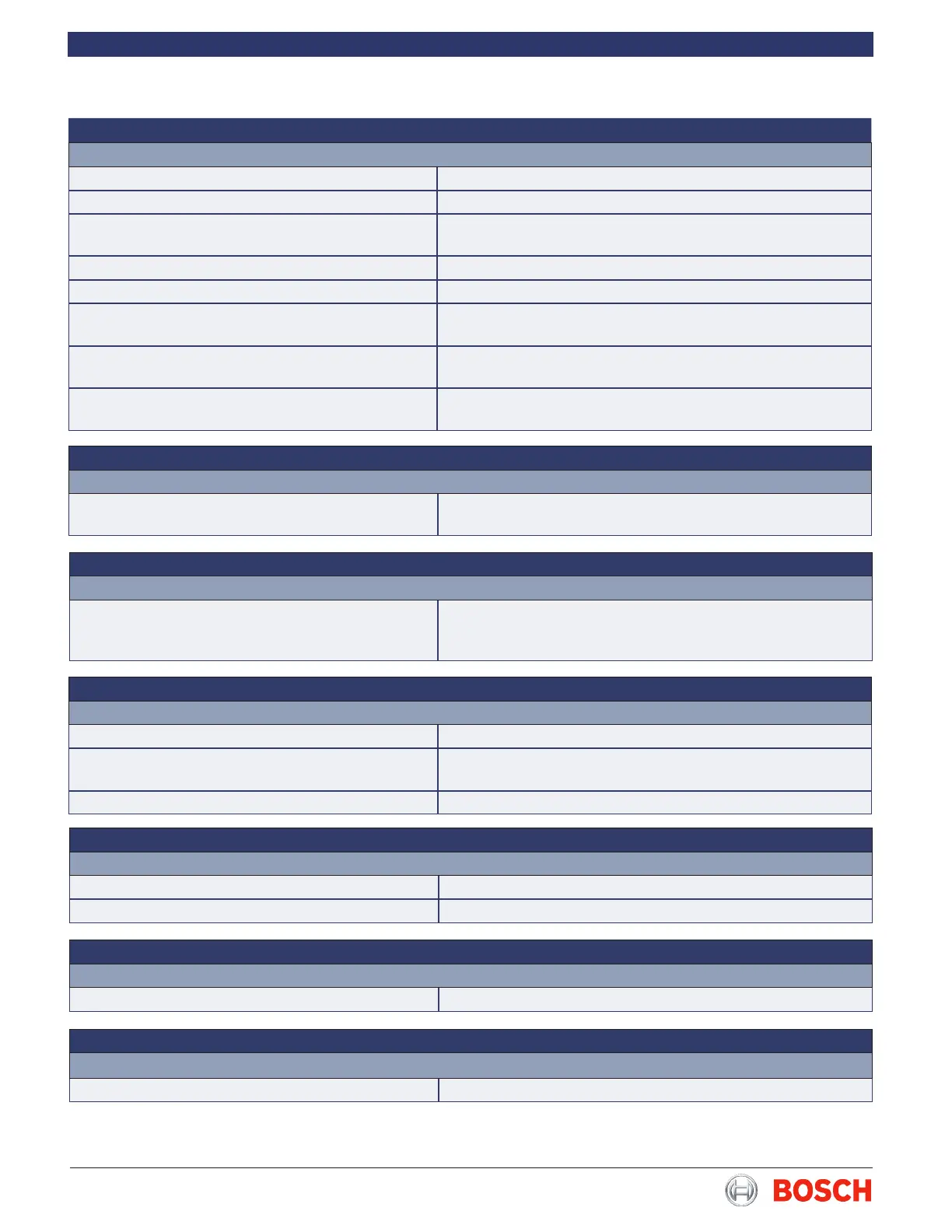

Problem: A Crimper is not being heated.

Possible Cause Solution

The crimper heating element connections are loose Tighten the heating element connections�

The crimper thermocouple connections are loose Tighten the thermocouple connections�

The crimper temperature controller connections are

loose

Have a qualied electrician tighten the temperature controller

connections�

The crimper heating element is faulty Replace the heating element�

The crimper thermocouple is faulty Replace the heating element containing the thermocouple�

The crimper temperature controller is faulty Have a qualied electrician replace the temperature control-

ler�

Faulty solid state relay� Using the electrical schematics, have a qualied electrician

check it out and/or consult Bosch�

The crimper collector ring assembly is faulty� Have a qualied electrician check the collector rings and

brushes and replace if necessary�

Problem: Product jams in the forming area and/or the cutting head.

Possible Cause Solution

The product is moving slower than the lm — the

infeed pitch is shorter than the product length Enter the correct infeed pitch and package length values�

Problem: The product not placed consistently inside package — it wanders or drifts inside package.

Possible Cause Solution

The lm is moving faster than the product when

they enter the former — the infeed pitch is shorter

than the package length

Enter a larger infeed pitch value and/or a smaller package

length value�

Problem: Cutoff fails to remain constant when running registered sealing material.

Possible Cause Solution

Electric eye not operating properly� Check registration eye setup and operation�

Registration marks on the material not printed cor-

rectly�

Check the material for proper spacing between the registra-

tion marks� Replace the sealing material if necessary�

Material is slipping in the nwheels. Check nwheel gap setting.

Problem: Package is crushed on the leading edge.

Possible Cause Solution

Pause is set incorrectly� Change the pause offset in the function list�

Problem: Sealing material snaps in the crimpers as they close.

Possible Cause

Solution

Pause is set incorrectly Change the pause offset in the function list�

Problem: Endseal crimpers hit product when closing

Possible Cause Solution

Infeed is out of time� Change the product offset in the functions list�

Pause is set incorrectly� Change pause offset in the function list�

Loading...

Loading...