Pack201 | Operator Interface | Section 4

EN | 45

© Bosch Packaging Technology, Inc.

All rights reserved 2012

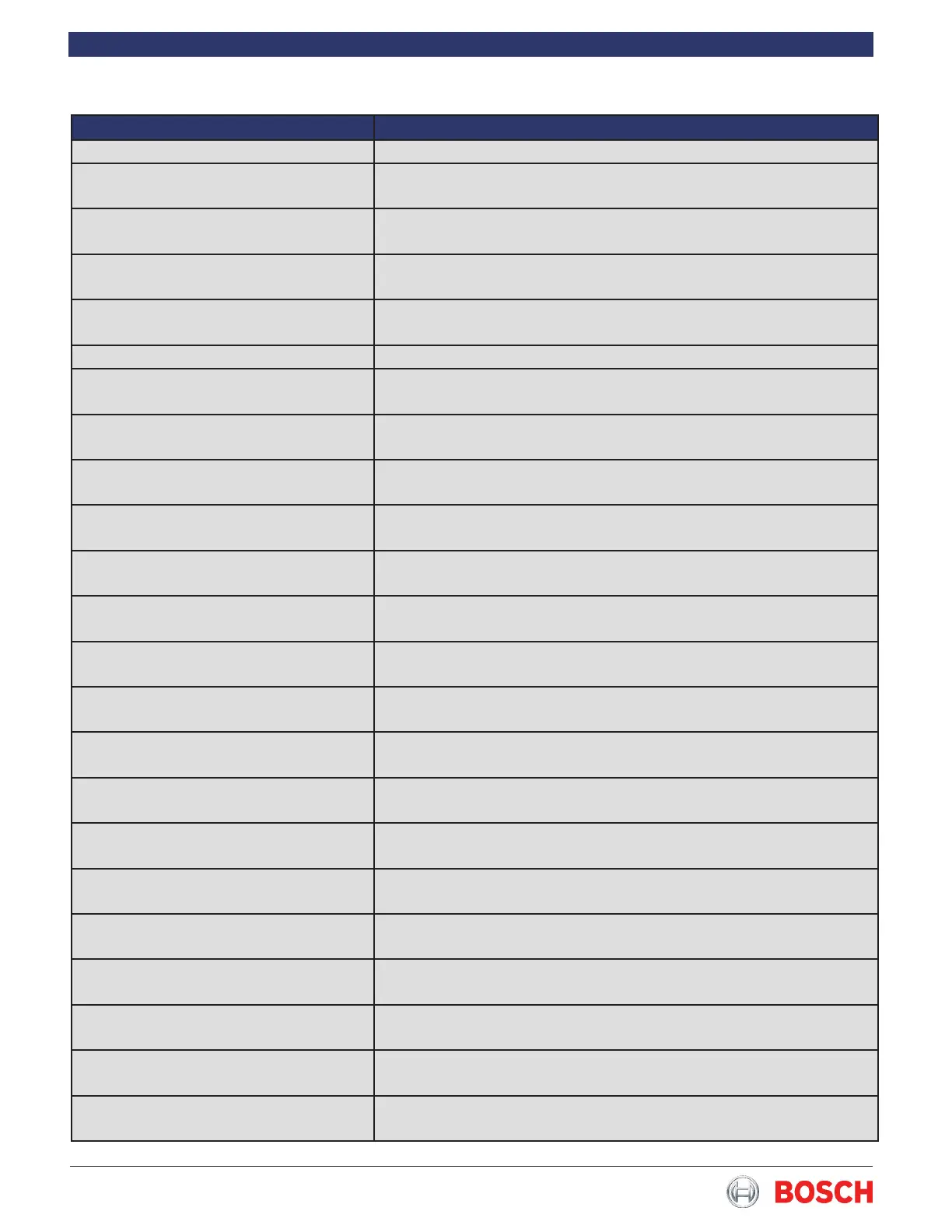

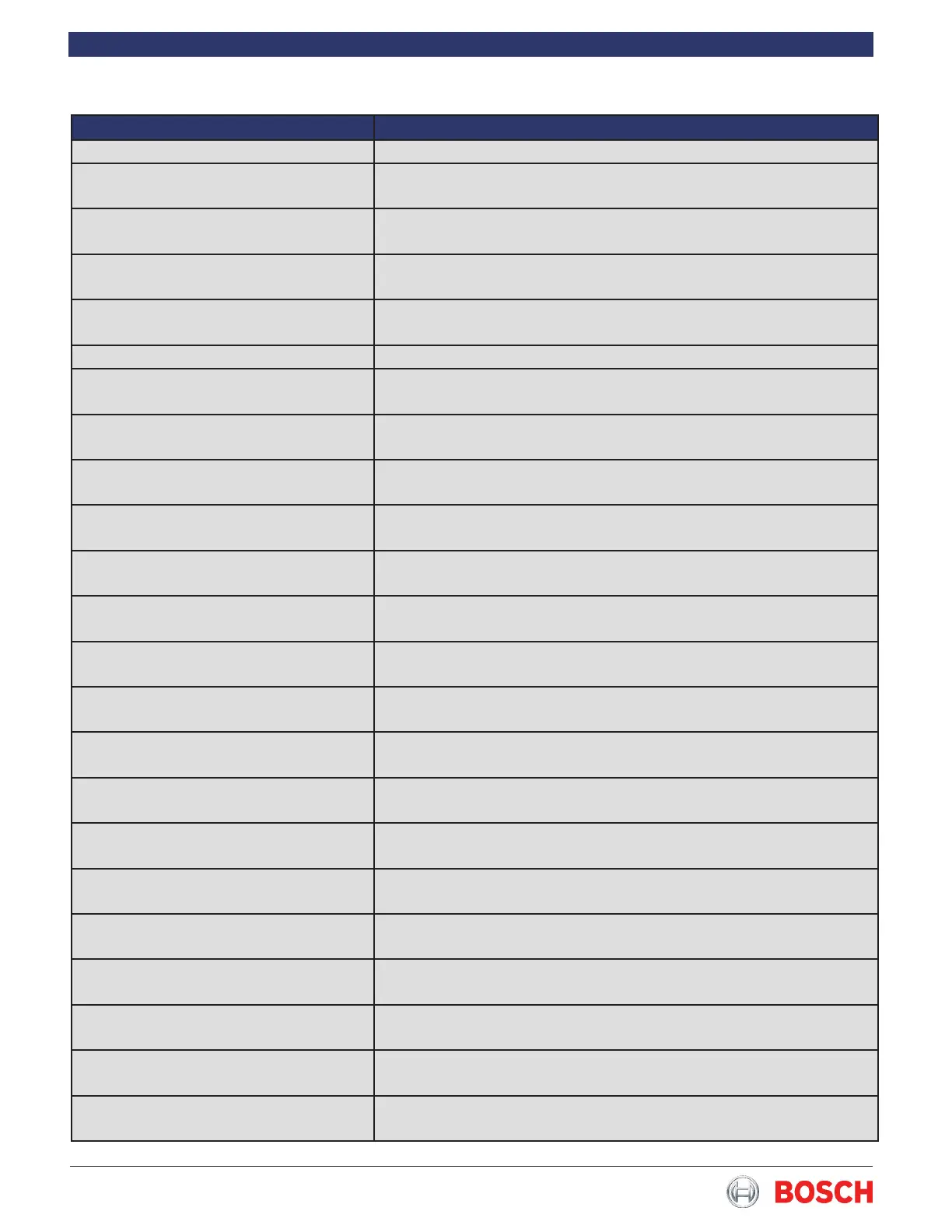

PARAMETER DEFINITION

Angle On Pulse X (deg) This is the position in a cycle where pulse X begins�

Angle On Reject Verify (deg) This is the position in a cycle where the verication eye starts to check

for a product�

Angle On Short Product Reject (deg) This is the position in a cycle where the short product reject eye starts

checking for a short product�

Angle On Tucker (deg) This is the position in a cycle where the air tucker starts to activate for a

tuck in the package�

Angle On Uncut Reject (deg) This is the position in a cycle where the uncut eye starts to check for an

uncut package�

Angle On Window Stop This is the position in a cycle where the stop window begins�

Auto Delay Off (mm) This is a delay added to prevent the wrapper from stopping as soon as

the No Product eye is unblocked�

Auto Delay On (mm) This is a delay added to prevent the wrapper from starting as soon as

the No Product eye is blocked�

Backlog Belt Accel Begin This is the point during a machine cycle at which the backlog belt starts

to accelerate to high speed�

Backlog Belt Decel Begin This is the point during a machine cycle at which the backlog belt starts

to decelerate to low speed�

Backlog Belt Hi Rate Accum Hi Speed

Ratio (%)

This is a percent of the backlog belt base rate used to set the high

speed required while product is fed into the sweep area�

Backlog Belt Lo Rate This is a percent of the backlog belt base rate used to set the low speed

required during the product transfer�

Backlog Gap Close Eye Enable In the ON position the backlog gap closing eye is active� In the OFF posi-

tion the eye is disabled�

Backlog Gap High Delay (mm) This is the distance the backlog eye is unblocked before the backlog belt

speeds up�

Backlog Gap High Ratio (%) This is a ratio of the backlog belt speed to 100 to 200% of the base

speed when the speed eye is blocked�

Backlog Gap Low Delay (mm) This is the distance the backlog eye is blocked before the backlog belt

slows down�

Backlog Gap Low Ratio (%) This is a ratio of the backlog belt speed to 50 to 100% of the base speed

when the speed eye is unblocked�

Backlog To Infeed Ratio (%) This is the ratio between the backlog belt speed and the infeed chain

speed�

Coder Enable In the ON position the coder is active� In the OFF position the coder is

disabled�

Coder Offset This is a correction that may be added to change the position of the

code on the package�

Consecutive Rejects Allowed This is the maximum number of consecutive reject conditions detected

allowed before the wrapper stops�

Cut Head to (Pusher) Dropout (mm) This is the measured distance from the closed crimpers to the point

where the infeed pusher last contacts the product�

Cut Position (mm)

(See Registration Offset)

This is the position of the cutoff on a package when running registered

lm.

Loading...

Loading...