RE 91485-01-B/2021-11-18, BoschRexrothAG

Transport and storage | A10FZO/G, A10VZO/G 27/72

Size 10 18 28 63

Width mm Dimensions vary by equipment. The values applicable for

your axial piston unit can be found in the installation drawing

(request if necessary).

Height mm

Depth mm

Weight may vary by equipment.

6�1�1 Transport by hand

Up to aspecific maximum weight, axial piston units can be transported by hand

for ashort distance. Observe the national regulations in your country. To prevent

health damage, we recommend renouncing any transport by hand.

CAUTION! Risk of injury due to heavy loads!

Health hazard from carrying axial piston units.

▶ Only manually transport the axial piston unit for ashort period of time.

Observe the national regulations in your country for manual transport.

▶ Always use appropriate lifting, lowering and moving techniques.

▶ Use your personal protective equipment (e.g.safety goggles, safety gloves,

suitableworking clothes, safety shoes).

▶ Do not transport the axial piston unit by sensitive assembled parts

(e.g.sensors or valves).

▶ Carefully place the axial piston unit on the seating to prevent it from being

damaged.

6�1�2 Transport with lifting devices

For transporting, the axial piston unit can be connected to alifting device via an

eye bolt or alifting strap.

The axial piston unit can be transported suspended from an eye bolt screwed into

the drive shaft as long as only outward (pulling) axial forces are applied.

▶ For all female threads, use astud end from the same system of units and of the

correct size.

▶ To do this, screw an eye bolt completely into the female thread on the drive

shaft. The thread size is indicated in the installation drawing.

▶ Make sure that the eye bolt can bear the total weight of the axial piston unit

plus 20%.

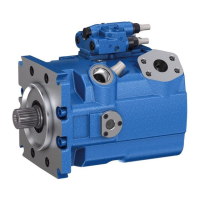

You can lift the axial piston unit as shown in Abb. 10 with the eye bolt screwed

into the drive shaft.

Transporting with eye bolt

Loading...

Loading...