BoschRexrothAG, RE 91485-01-B/2021-11-18

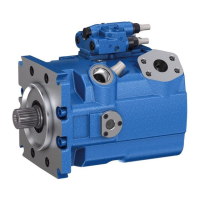

58/72 A10FZO, A10VZO, A10FZG and A10VZG series 10 | Operation

9 Operation

This product is acomponent which requires no settings or changes during

operation. For this reason, this chapterof the manual does not contain any

information on adjustment options. Use the product only within the performance

range specified in the technical data. The machine/system manufacturer is

responsible for proper project planning of the hydraulic system and its control.

10 Maintenance and repair

NOTICE

Overdue inspection and maintenance work!

Property damage!

▶ Perform the specified inspection and maintenance work at the intervals

described in this manual.

10�1 Cleaning and care

NOTICE

Damage to seals and electrical system due to mechanical effects!

The jet of ahigh-pressure cleaner may damage the seals and electrical system of

the axial piston unit!

▶ Do not point ahigh-pressure cleaner at sensitive components, e.g.shaft seal,

electrical connections and components.

For cleaning and care of the axial piston unit, observe the following:

▶ Check whether all seals and plug-in connections are securely seated to ensure

no moisture can penetrate into the axial piston unit during cleaning.

▶ Use only water and, if necessary, amild cleaning agent to clean the

axial piston unit. Never use solvents or aggressive cleaning agents.

▶ Remove major external contamination and keep clean sensitive and important

components, such as solenoids, valves, indicators and sensors.

10�2 Inspection

In order for the axial piston unit to be reliable and long-lasting, BoschRexroth

recommends inspecting the hydraulic system and axial piston unit on aregular

basis, and documenting and archiving the following operating conditions:

Loading...

Loading...