RE 91485-01-B/2021-11-18, BoschRexrothAG

Installation | A10FZO/G, A10VZO/G 45/72

3

4

1

1

1

2

1

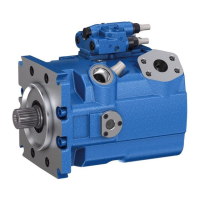

Abb� 26: Removal of transport protection, example A10FZG and A10VZG

1 Protective covers

2 Protective plugs/threaded plugs

3 For version with through drive,

protective cover and mounting bolts

4 Transport protection for the through drive

Ports intended for connecting lines come with protective plugs and/or

threaded plugs, which serve as transport protection. All ports required

for the function must be connected (see Tabelle 25 to Tabelle 28

"Ports A10FZO, A10VZO, A10FZG and A10VZG" starting on page48). Failure

to do so could lead to malfunctions or damage. If aport is not being used, plug

it with athreaded plug since the protective plugs are not pressure-resistant.

7�5�7 Hydraulically connecting the axial piston unit

NOTICE

Insufficient suction pressure!

Generally, aminimum permissible suction pressure at portS(A/B) is specified

for axial piston pumps in all installation positions. If the pressure at portS(A/B)

drops below the specified values, damage may occur which may lead to the

axial piston pump being damaged beyond repair!

▶ Make sure the required suction pressure is maintained. This is influenced by:

– The piping (e.g.suction cross-section, pipe diameter, length of suction line)

– The position of the reservoir

– The viscosity of the hydraulic fluid

– A filter element or check valve in the suction line (check the level of

contamination of the filter element regularly)

– The geodesic height of the place of use

CAUTION

Incorrectly connected suction and pressure lines!

Risk of injury and property damage!

▶ Make sure that the corresponding suction and pressure port is assigned to the

correct direction of rotation. Information on this can be found in data sheet

91485 and in Tabelle 7 to Tabelle 9 "Flow direction" starting on page24.

Loading...

Loading...