RE-A 91610/12.2015, Bosch Rexroth Corp.

Axial piston variable motor | A6VM series 71

Counterbalance valve BVD and BVE

65

Counterbalance valve BVD and BVE

Function

Counterbalance valves for drives and winches should

reduce the danger of overspeed and cavitation in open

circuits of axial piston motors. Cavitation occurs if, during

braking, when going downhill or during the load-lowering

process, the motor speed is greater than it should be for

the given inlet flow and thus the inlet pressure collapses.

If the inlet pressure falls below the level specified for the

relevant counterbalance valve, the counterbalance valve

piston moves into the closed position. The cross-sectional

area of the counterbalance valve return duct is then

reduced, creating a restriction in the return flow of the

hydraulic fluid. The pressure increases and brakes the

motor until the speed of the motor reaches the specified

value for the given inlet flow.

Note

▶ BVD available for sizes 60 to 215 and BVE available for

sizes 115 to 215.

▶ The BVD counterbalance valve must be ordered addi-

tionally. We recommend ordering the counterbalance

valve and the motor as a set.

Order example:A6VM085HA1T30004A/71AWV0C2

97W0-0 + BVD20F27S/41B–V03K16D0400S12

▶ For safety reasons, controls with beginning of control at

V

g

min

(e.g. HA) are not permissible for winch drives!

▶ Counterbalance valves must be optimized during proto-

type commissioning to prevent unacceptable operating

conditions and compliance with the specification must

be verified.

▶ The counterbalance valve does not replace the mechani-

cal service brake and parking brake.

▶ Observe the detailed notes on the BVD counterbalance

valve in RE 95522 and BVE counterbalance valve in

RE 95525.

▶ For the design of the brake release valve, we require the

following data for the mechanical holding brake:

– the cracking pressure

– the volume of the brake spool between minimum

stroke (brake closed) and maximum stroke (brake

released with 305psi (21bar))

– the required closing time for a warm device (oil

viscosity approx.69.6SUS (15mm

2

/s))

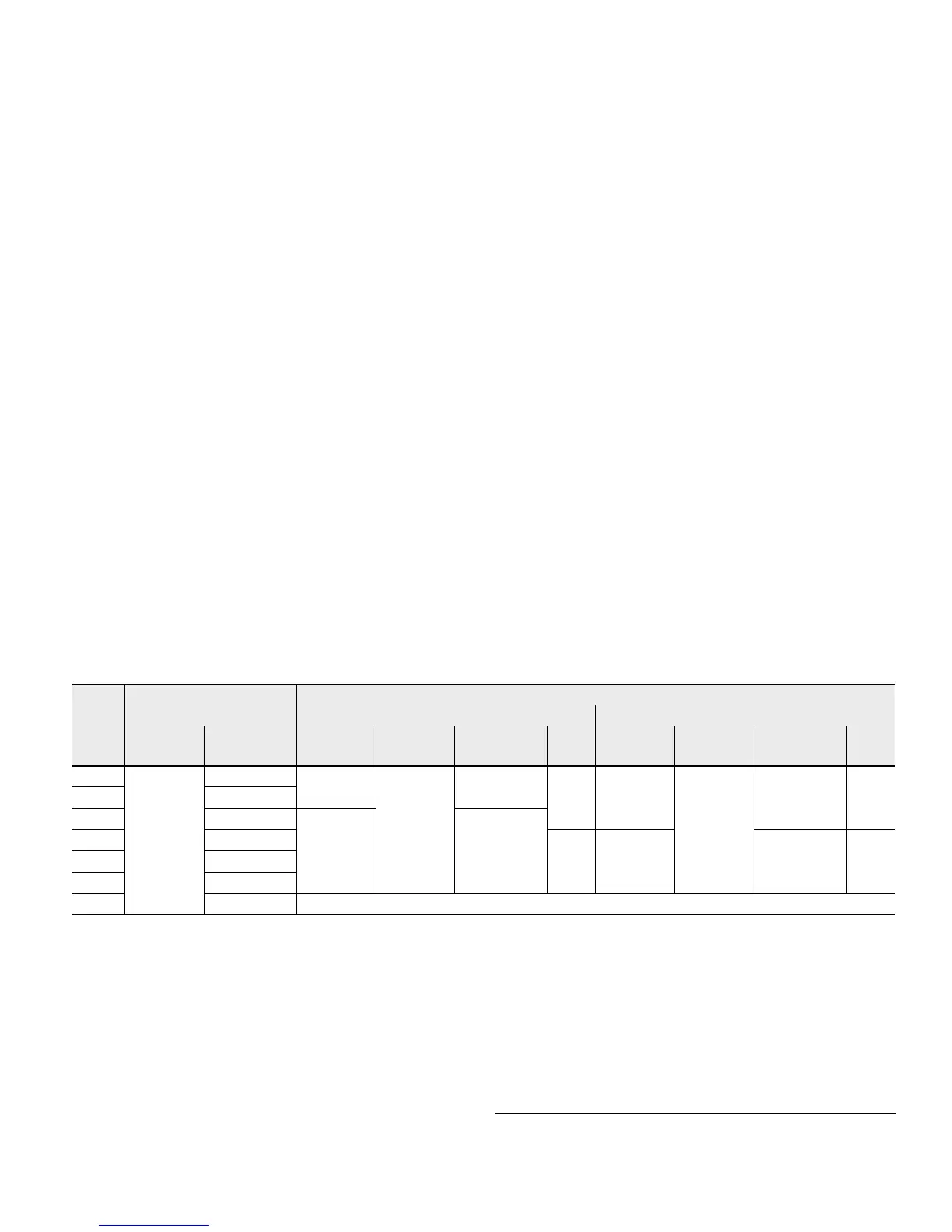

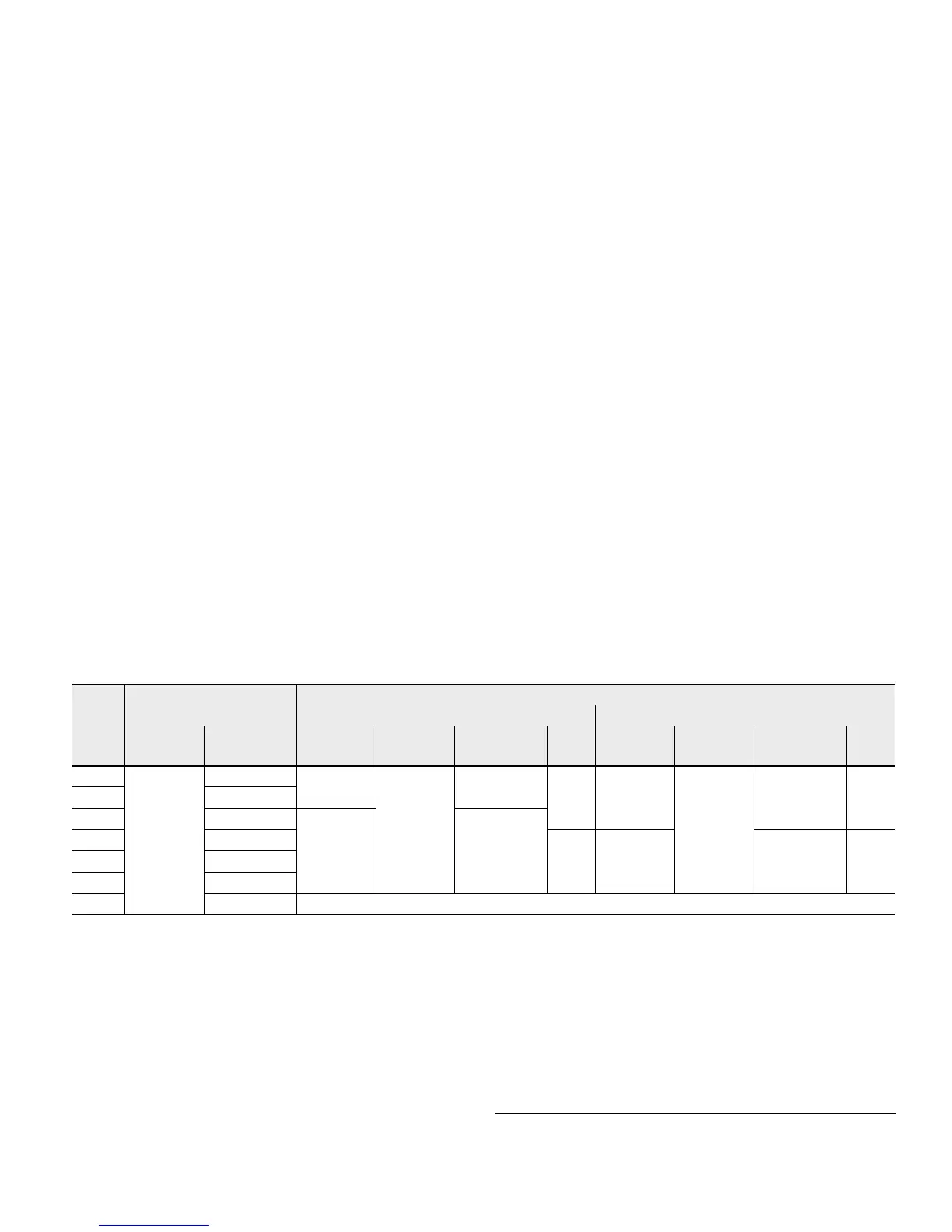

Permissible input flow or pressure when using DBV and BVD/BVE

Without valve Limited values when using DBV and BVD/BVE

Motor DBV

1)

BVD

2)

/BVE

3)

NG

p

nom

/p

max

[psi (bar)]

q

V max

[gpm (l/min)]

NG

p

nom

/p

max

[psi (bar)]

q

V

[gpm (l/min)]

Code NG

p

nom

/p

max

[psi (bar)]

q

V

[gpm (l/min)]

Code

60 6500 /7250

(450/500)

73 (276) 22 5100/6100

(350/420)

63 (240) 7 20

(BVD)

5100/6100

(350/420)

58 (220) 7W

85 88 (332)

115 108 (410) 32 106 (400)

115 108 (410) 8 25

(BVD/BVE)

85 (320) 8W

150 131 (494)

170 141 (533)

215 166 (628) On request

Mounting of the counterbalance valve

When delivered, the counterbalance valve is mounted to the

motor with two tacking screws (transport lock). The tack-

ing screws may not be removed while mounting the working

ports. If the counterbalance valve and motor are delivered

separately, the counterbalance valve must first be mounted

to the motor port plate using the provided tacking screws.

The final mounting of the counterbalance valve on the

motor is done with screw fitting of the SAE flange.

The screws to be used and the procedure mountings can be

found in the instruction manual.

1) Pressure-relief valve

2) Counterbalance valve, double-acting

3) Counterbalance valve, single-acting

Loading...

Loading...